Fuel gas low-nitrogen burner

A low-nitrogen burner and gas technology, applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of large fluctuations in flow parameters and reduce the generation of nitrogen oxides, and achieve small fluctuations in flow parameters and reduce nitrogen The amount of oxide generation and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

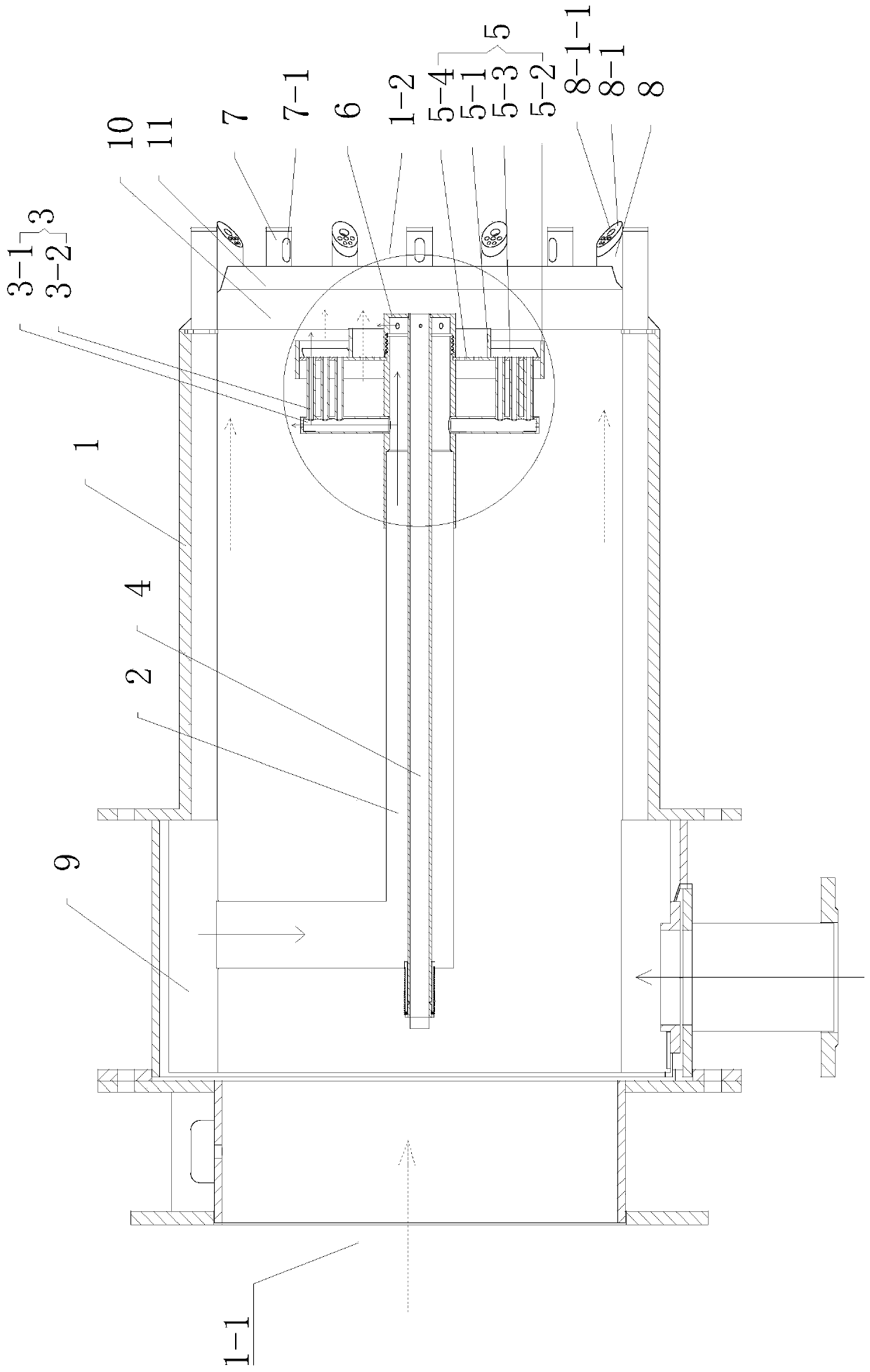

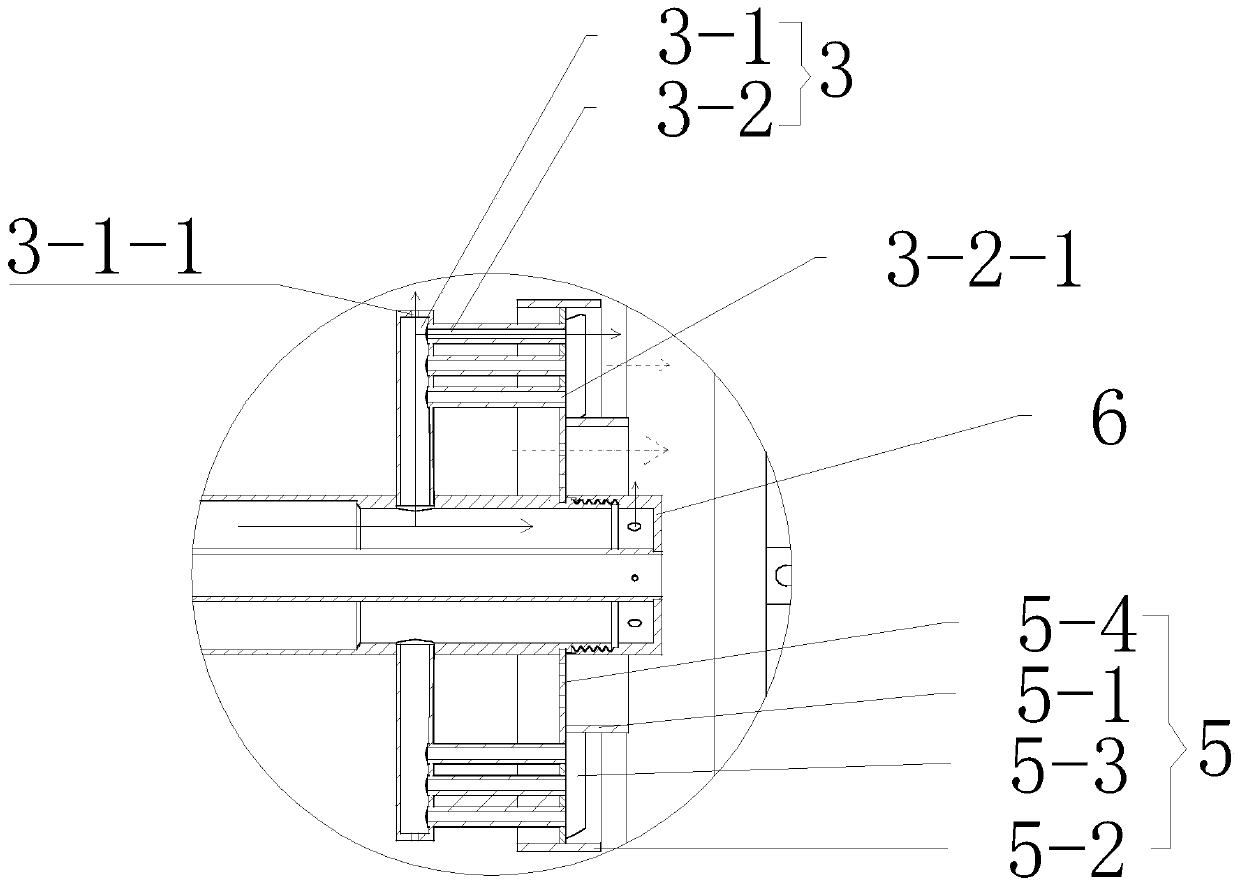

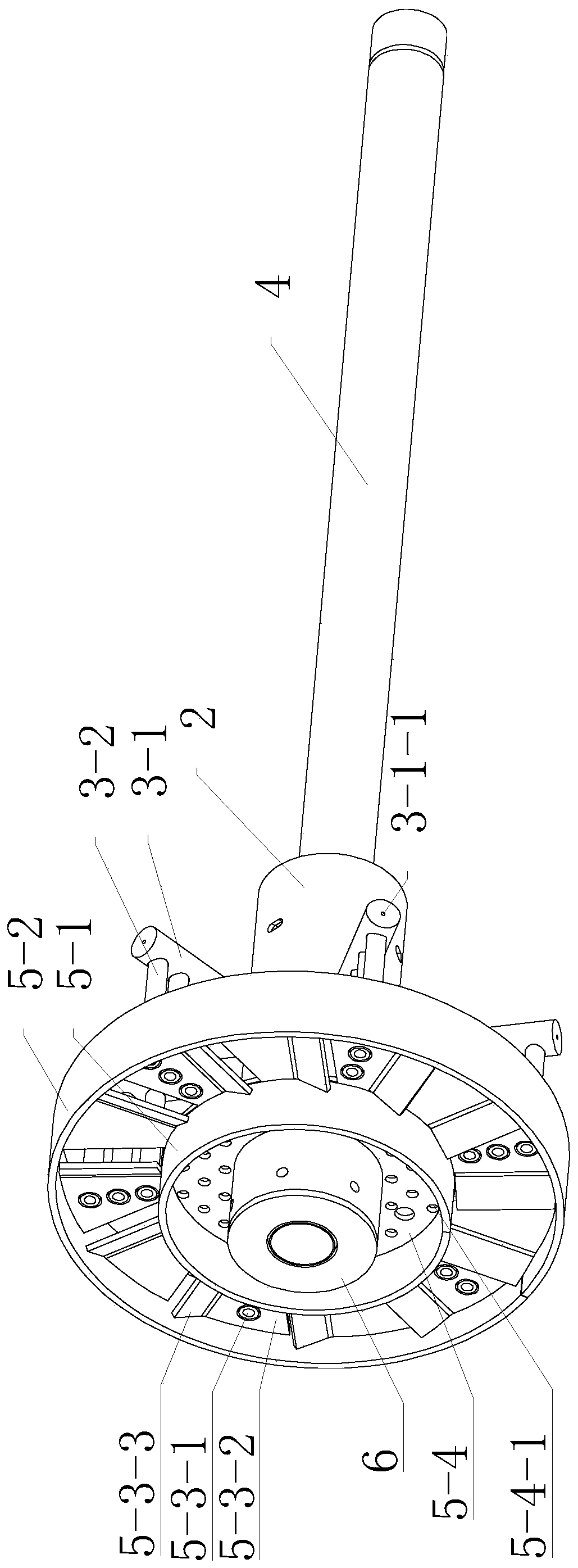

[0060] The following is attached with the manual Figure 1-7 The technical solution of the present invention is described in detail.

[0061] like Figure 1-7 As shown, a gas low-nitrogen burner according to the present invention includes a cylinder, a gas supply device, an ignition device and a swirl disk,

[0062] The cylinder is a hollow cylinder, the rear end is an air inlet, and the front end is an air outlet;

[0063] The gas supply device includes a central gas main pipe and a central gas branch pipe; the central gas main pipe is arranged in the inner cavity of the cylinder and extends along the central axis of the cylinder, the gas inlet end of the central gas main pipe is connected with the external gas supply device, and the gas outlet end is close to the air At the gas outlet; the central gas branch pipe includes multiple first-level distribution branch pipes, each of which extends radially along the central gas main pipe and is distributed along the circumferenti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com