Device for filtering naked flame particles in mixed flue gas

A flue gas and particle technology, applied in the field of filtration and fire prevention, can solve the problems of unsuitable flue gas and the reduction of flue gas temperature, and achieve the effect of reducing loss, uniform particle size and providing coal quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

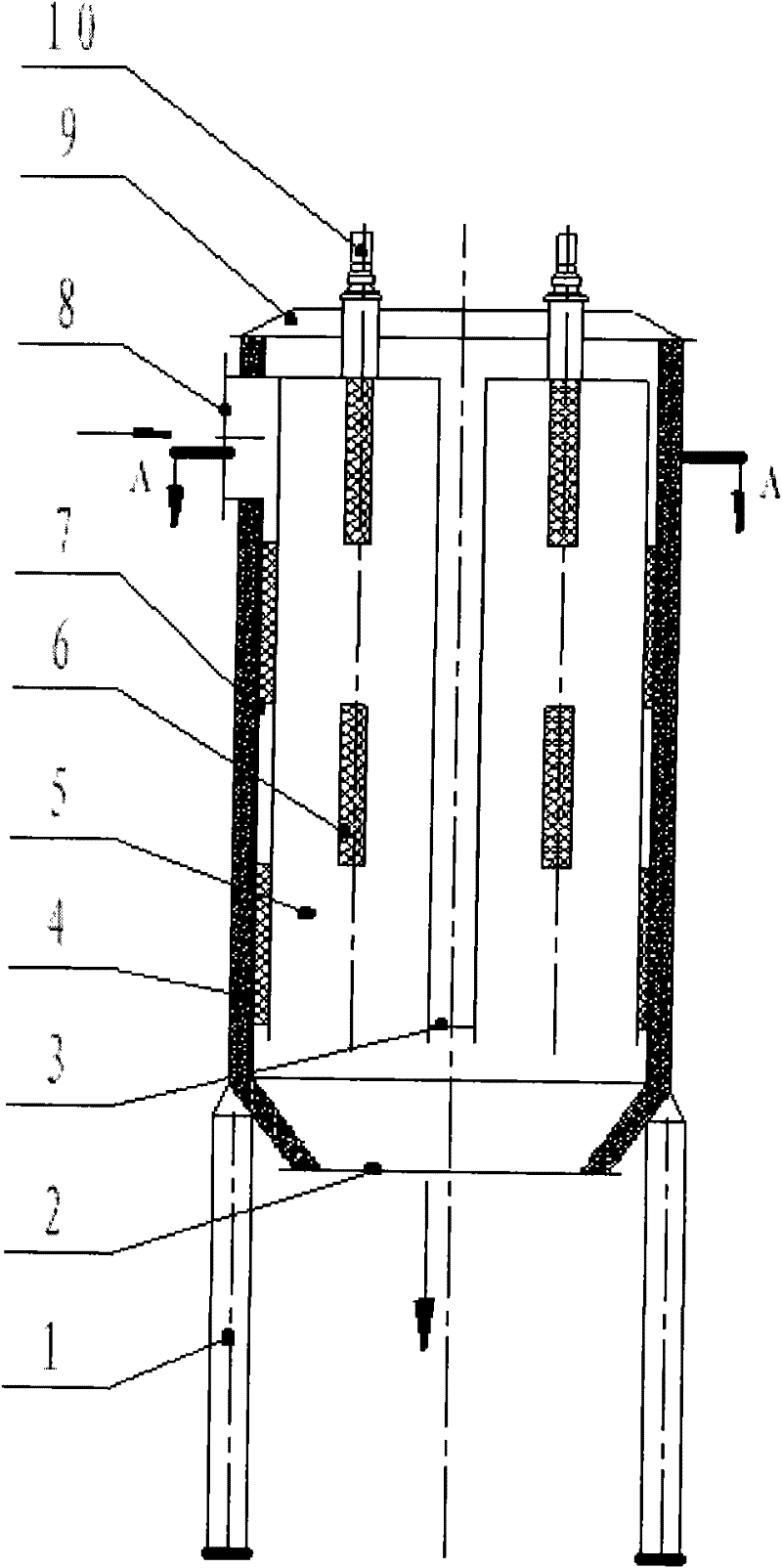

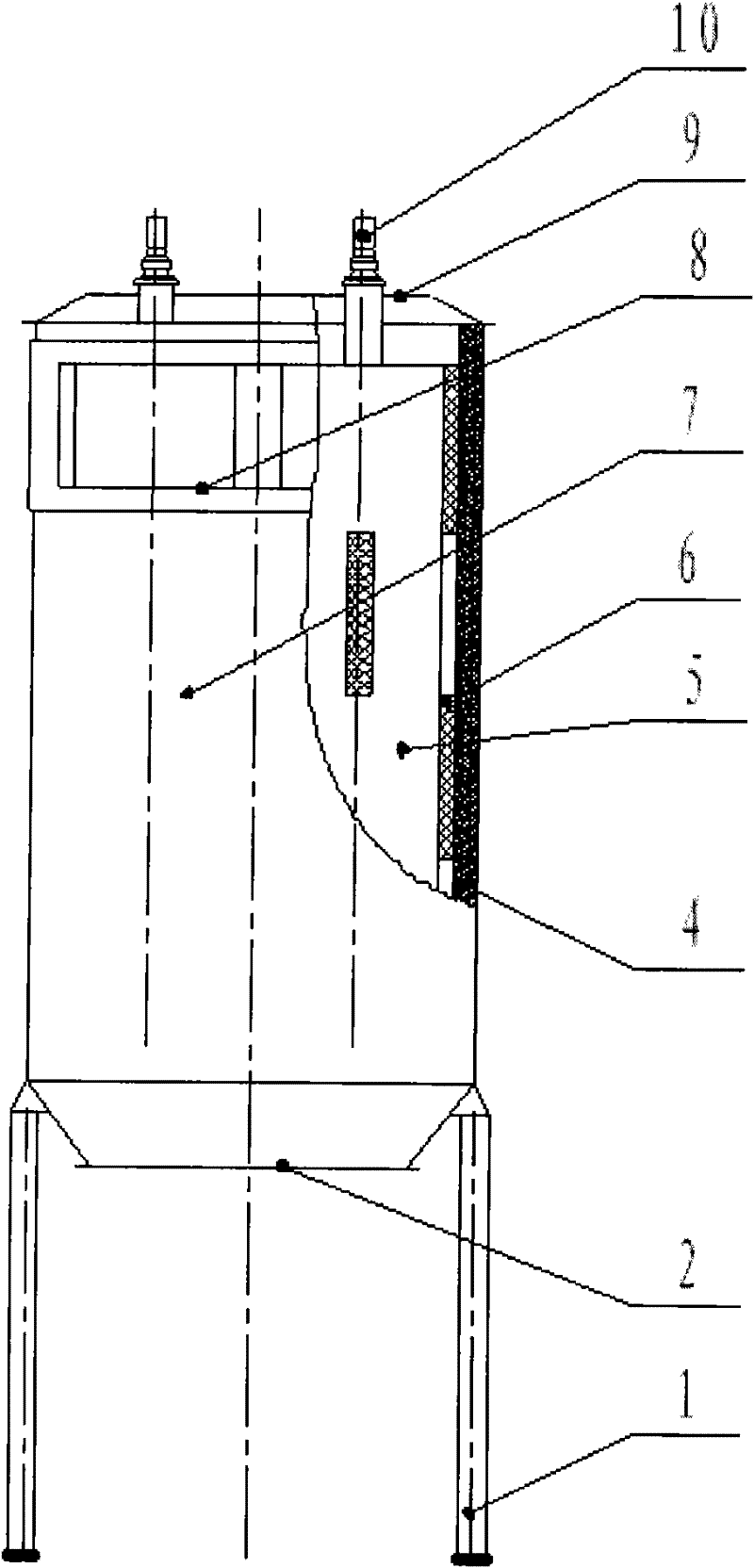

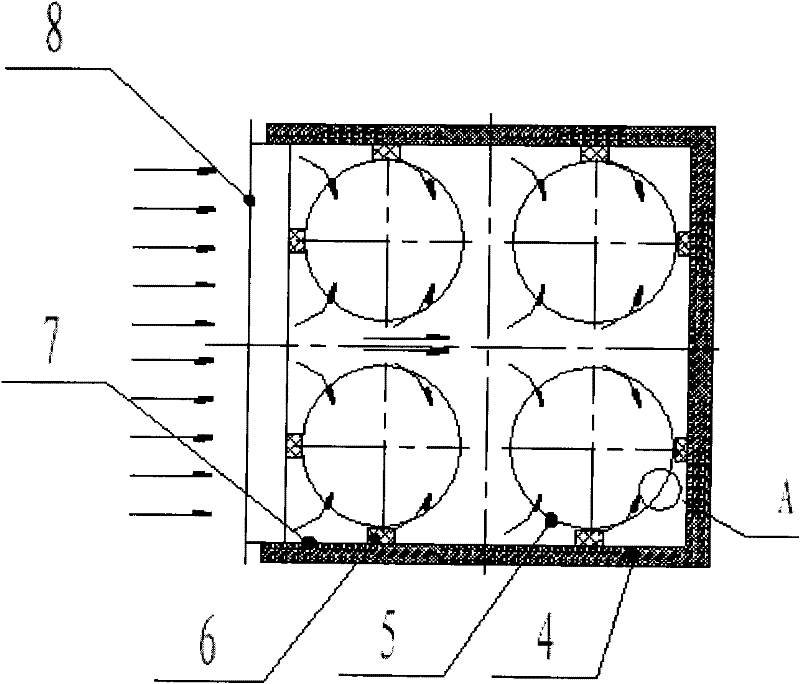

[0017] According to the technical scheme and accompanying drawings of the invention. Parts and their reference signs are indicated as follows:

[0018] Support 1, air outlet 2, retaining ring 3, insulation layer 4, screen cylinder 5, cleaner 6, box body 7, air inlet 8, upper cover 9, transmission device 10, strip wire mesh 11.

[0019] exist Figure 1-4 middle, figure 1 It is the main cross-sectional view of the device for filtering spark particles in the mixed smoke; figure 2 It is a partial cross-sectional view of the device for filtering spark particles in mixed smoke; image 3 is along figure 1 The cross-sectional view cut by A-A in the middle; Figure 4 is a cross-sectional view of the strip wire mesh covering the surface of the screen drum.

[0020] In the device for filtering spark particles in mixed smoke of the present invention, the mixed smoke is smoke containing smoke gas and spark particles, and the device for filtering spark particles in mixed smoke can re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com