Needle combined device for weft insertion mechanism of water-jet loom

A technology of water jet loom and weft insertion mechanism, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of easy deformation of the spray needle combination device, pressure loss, difficult to arrange the spray needle, etc. The effect of compactness, reduced water pressure loss, and convenient arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

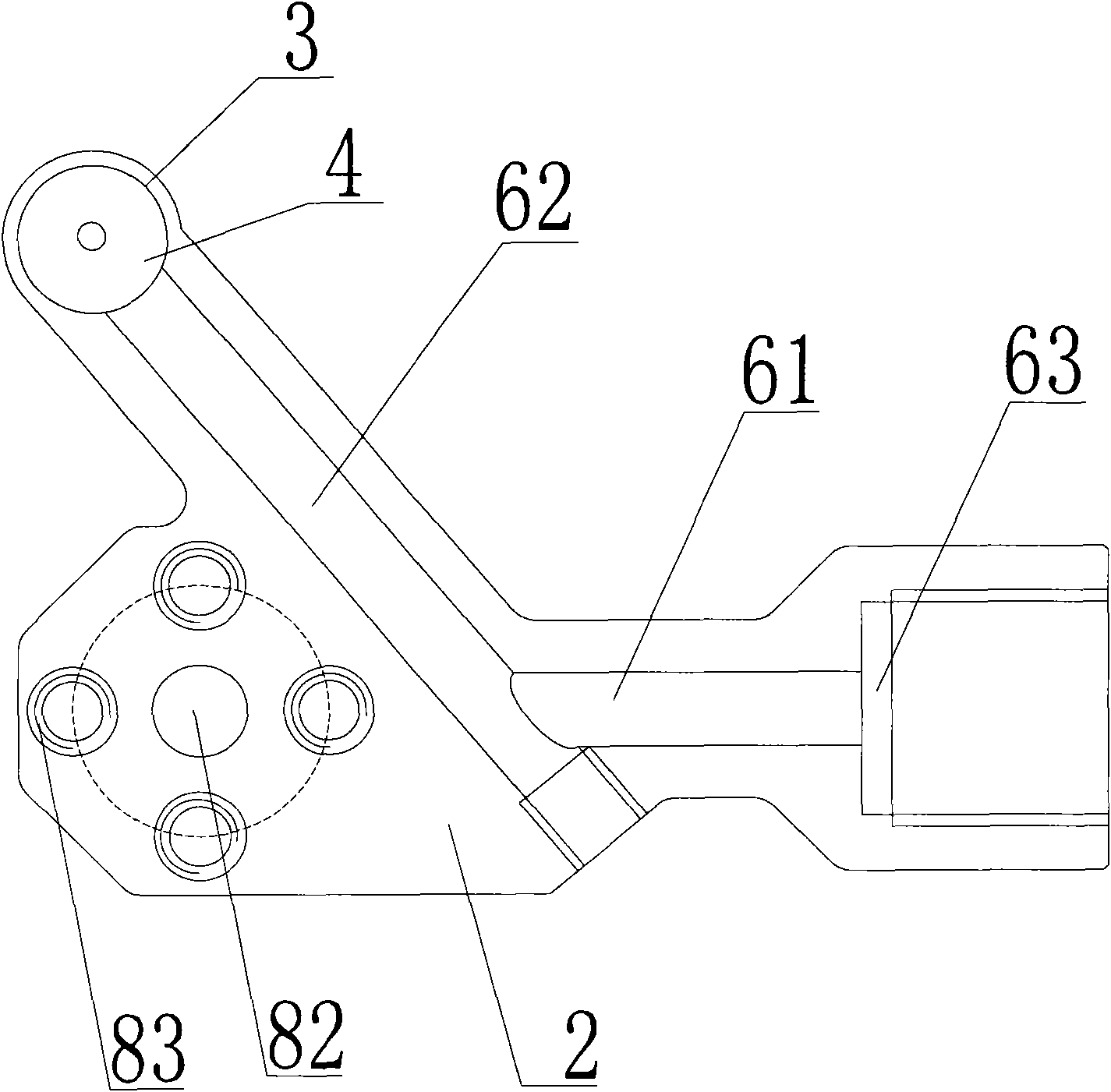

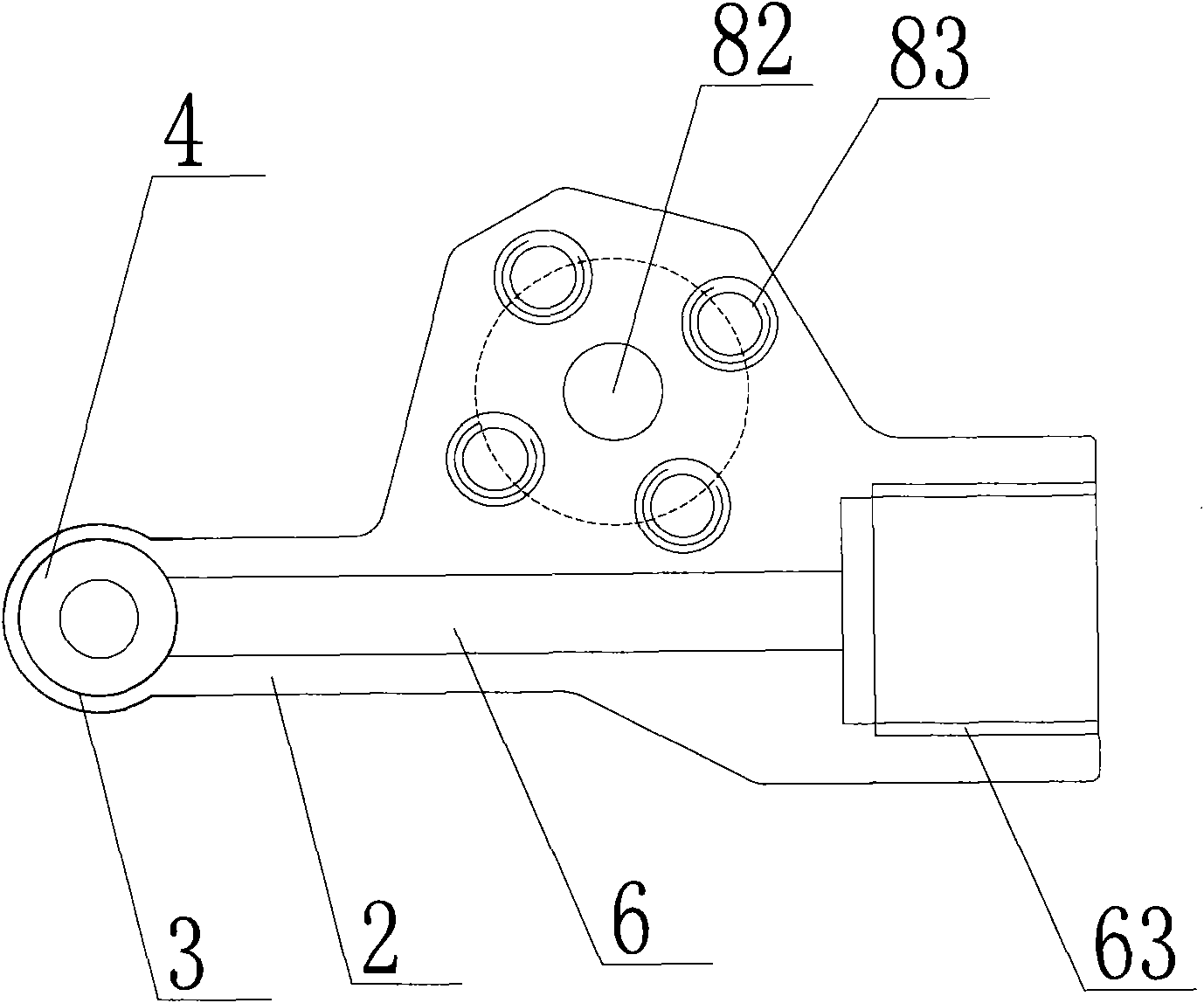

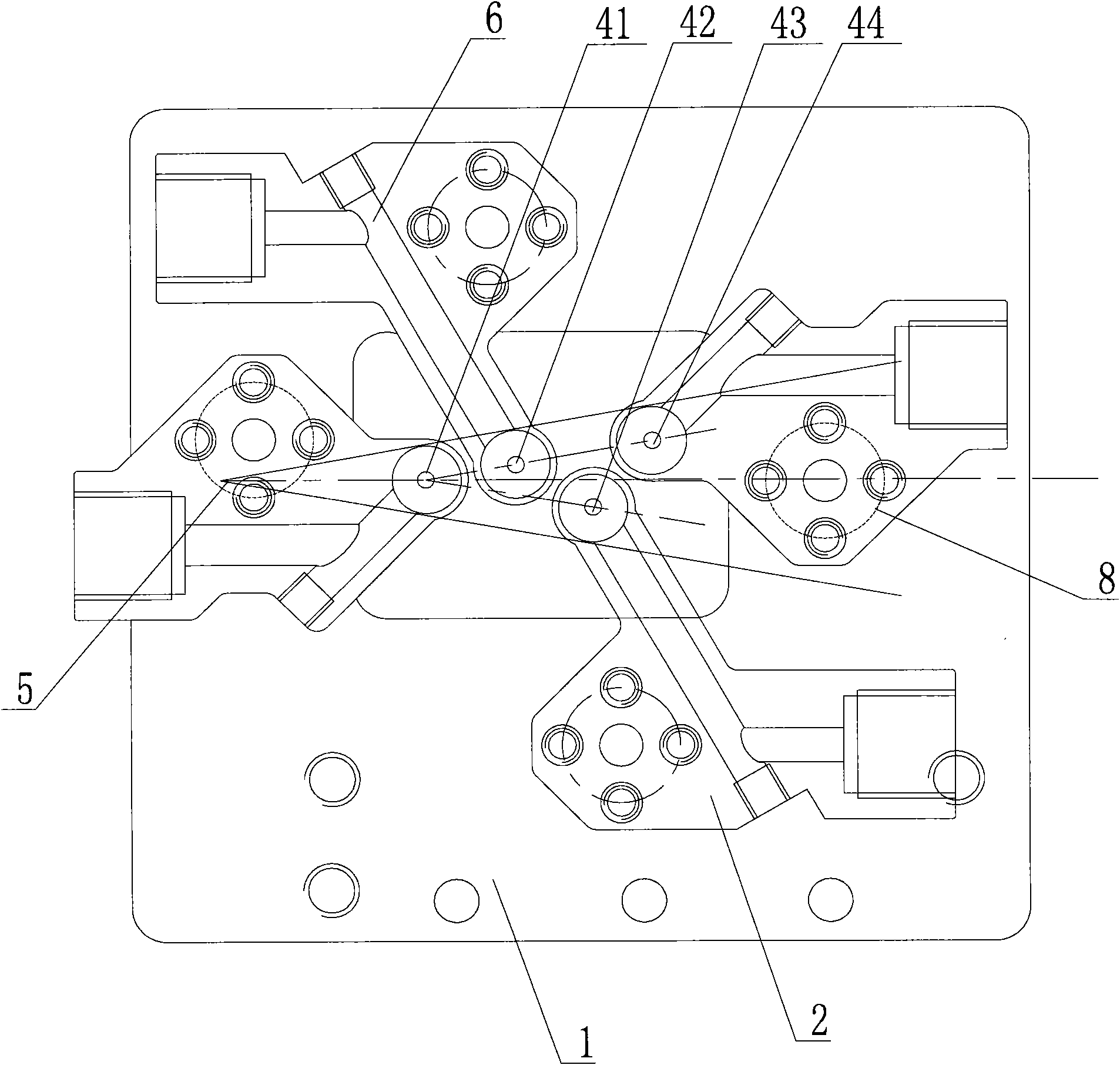

[0038] Example image 3 As shown, the needle combination device of the weft insertion mechanism of the water jet loom includes four needle bases 2 installed on the bracket 1, and each needle base 2 is provided with a mounting hole 3, and each mounting hole is equipped with Needle body 4, each needle body is equipped with a needle, the needles are arranged sequentially from the weaving mouth 5, including the first needle 41, the second needle 42, the third needle 43 and the fourth needle 44, The center of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com