Pipe bender

A pipe bending machine and frame technology, applied in the field of pipe bending machines, can solve the problems of large investment and difficult guarantee of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

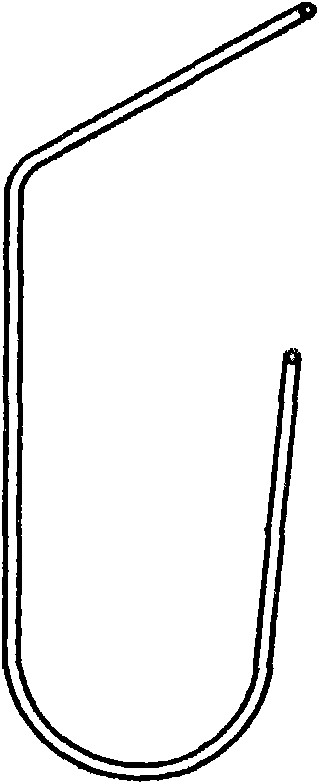

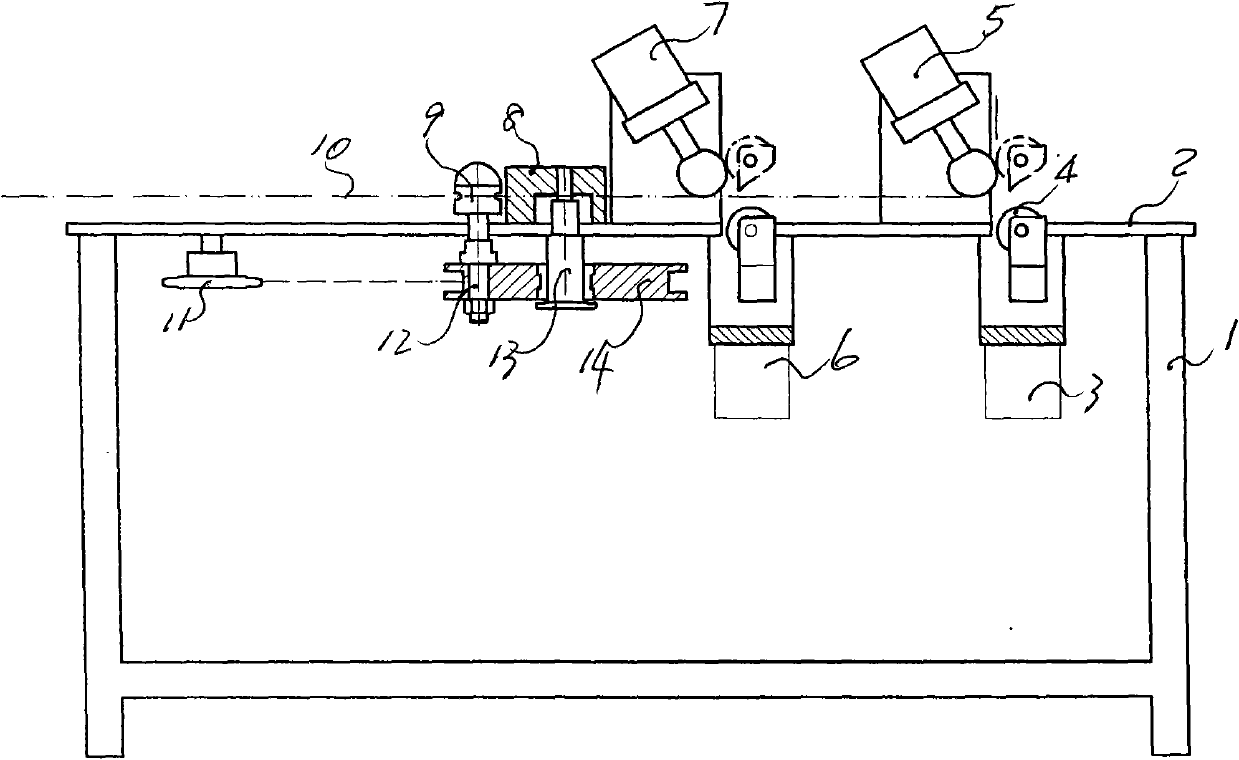

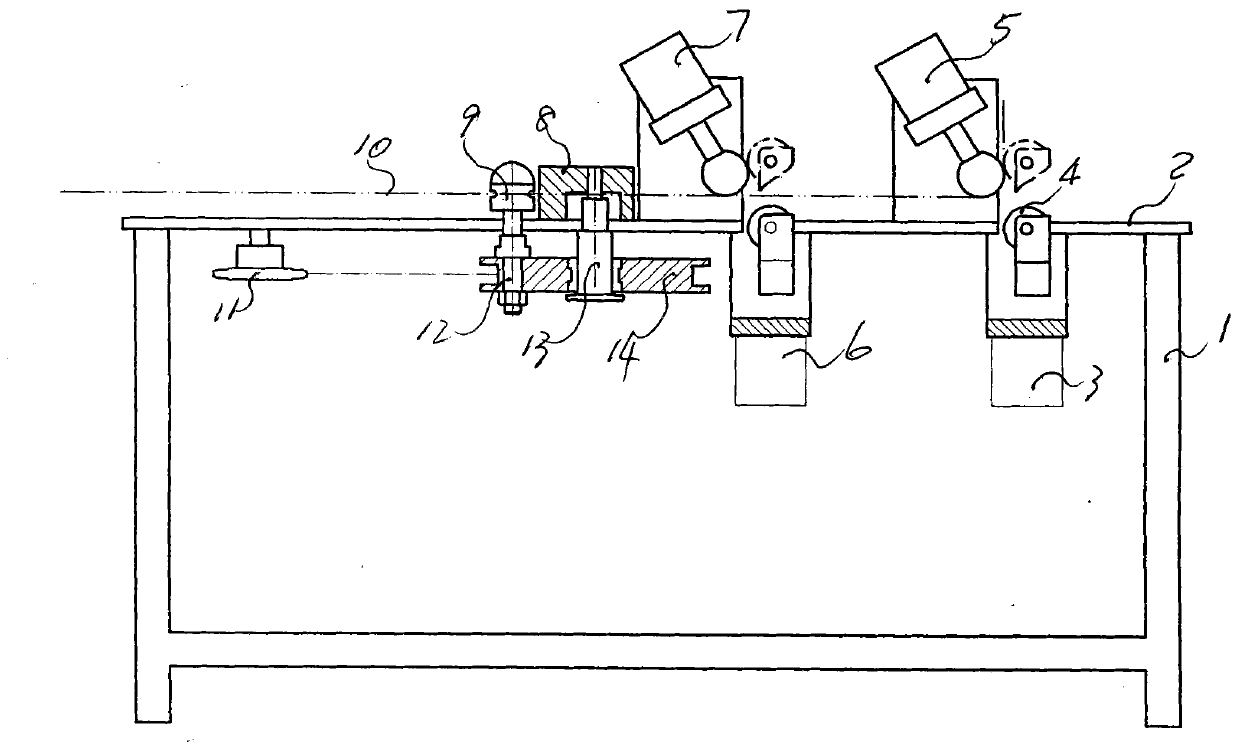

[0005] As a specific embodiment of the present invention, the above figure 1 , 2 It is a 120° bend and a 175° bend on the plane, and each of the two ends of the bend has a 90° bend perpendicular to the plane pipe. The pipe bender of the present invention can bend this pipe. There is a vertical first cylinder 3 under the platen 2 of the frame 1, and a roller 4 with an annular groove matching the bent pipe is arranged on its peripheral surface, and the roller is matched with the shaft on the piston rod of the cylinder 3, Above the platen opposite to this first cylinder 3 is provided with an inclined second cylinder 5, the piston end of this second cylinder has a rotating roller, the left outer edge of the roller on the piston rod of the first cylinder It is tangent to the outer edge of the right side of the roller on the piston rod of the second cylinder; a third cylinder 15 is arranged horizontally on the platen on the left side of the second cylinder, and the end of the pist...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap