Elastic side bearing for bogie and bogie

A bogie and elastic technology, applied in the field of railway vehicle bogie structure, can solve problems such as large unsprung weight, design structure restrictions, and restrictions on railway cargo transportation, so as to reduce stiffness, increase vertical deflection, and improve axle load and the effect of low dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

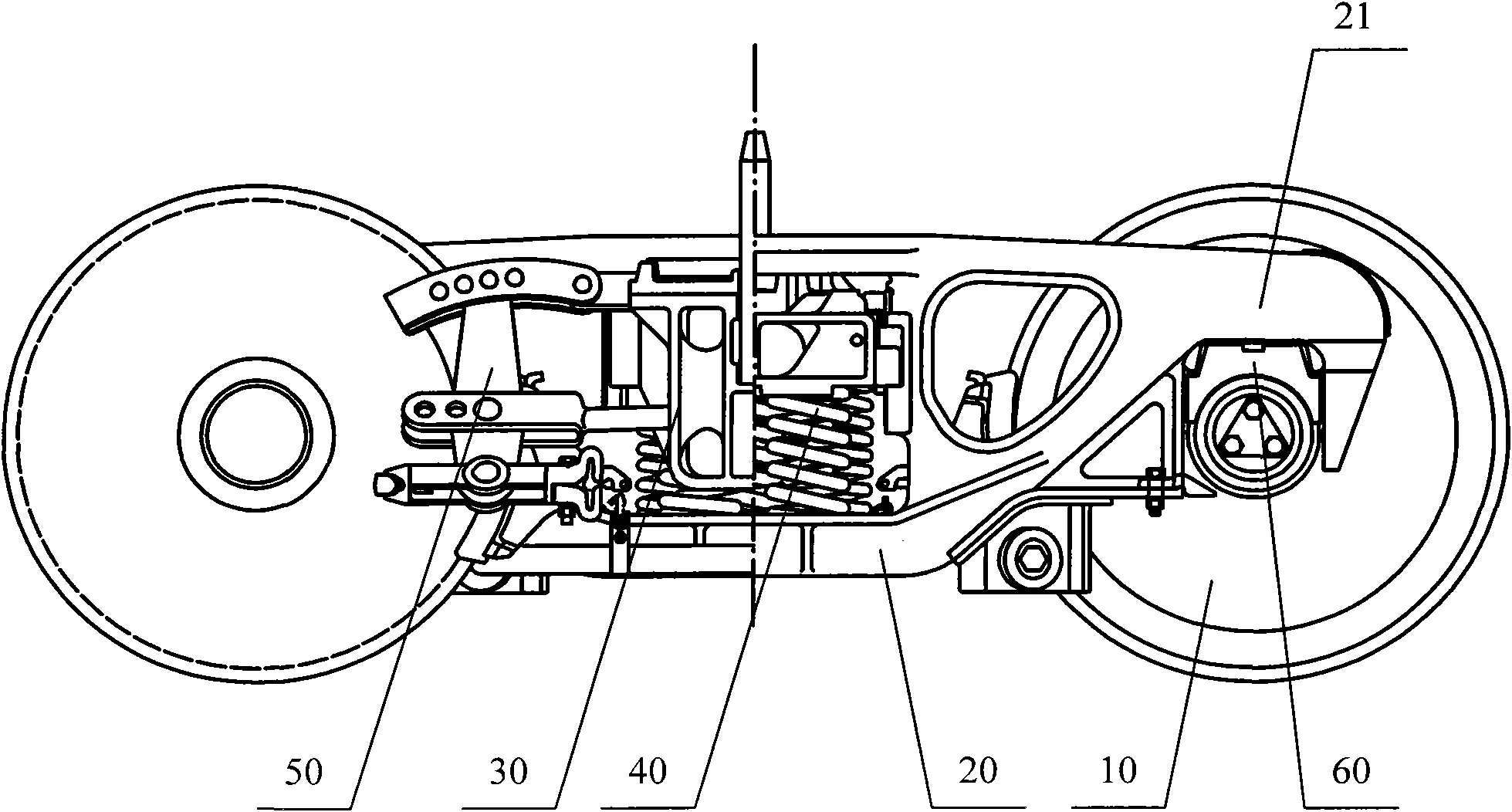

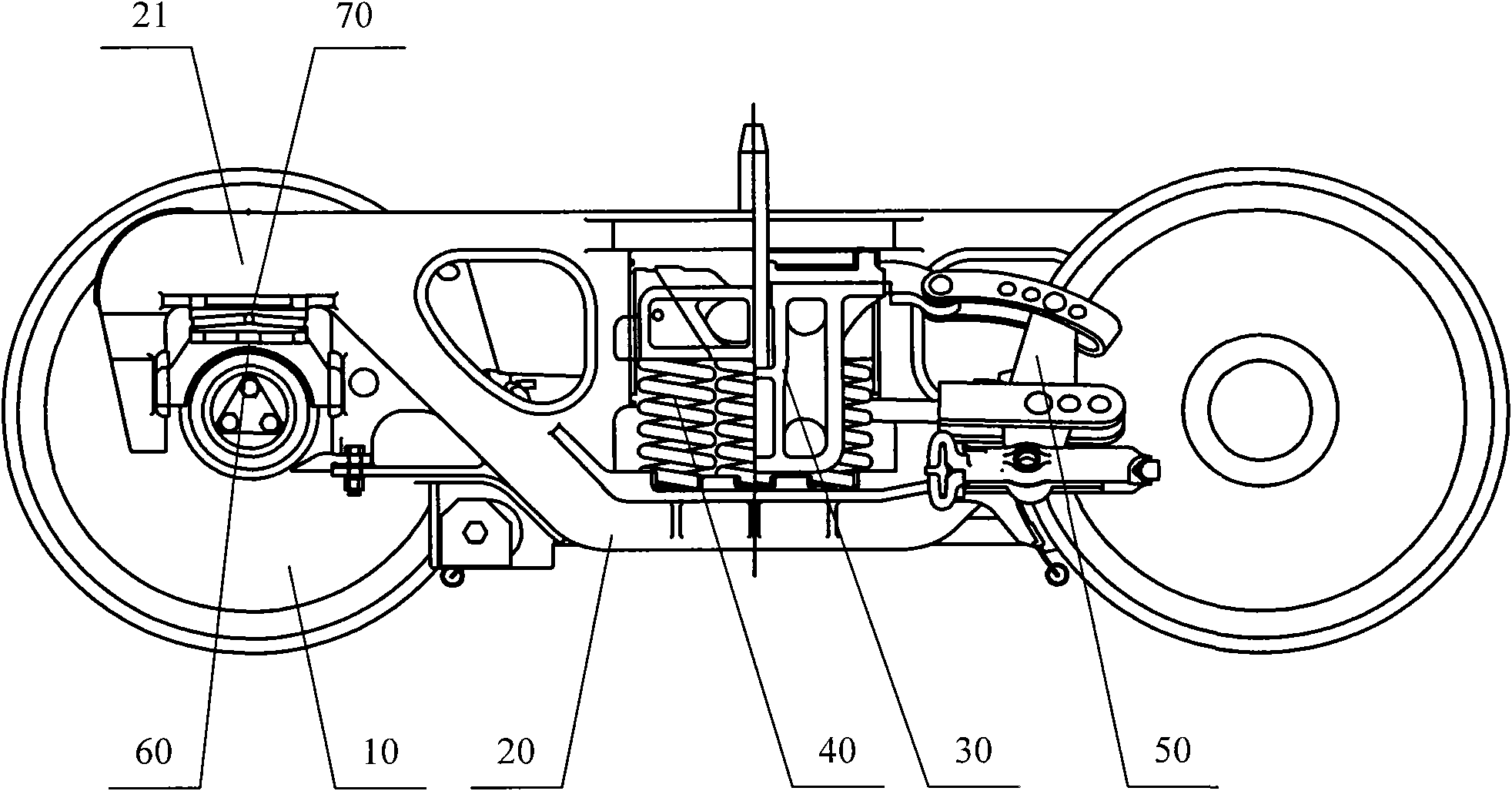

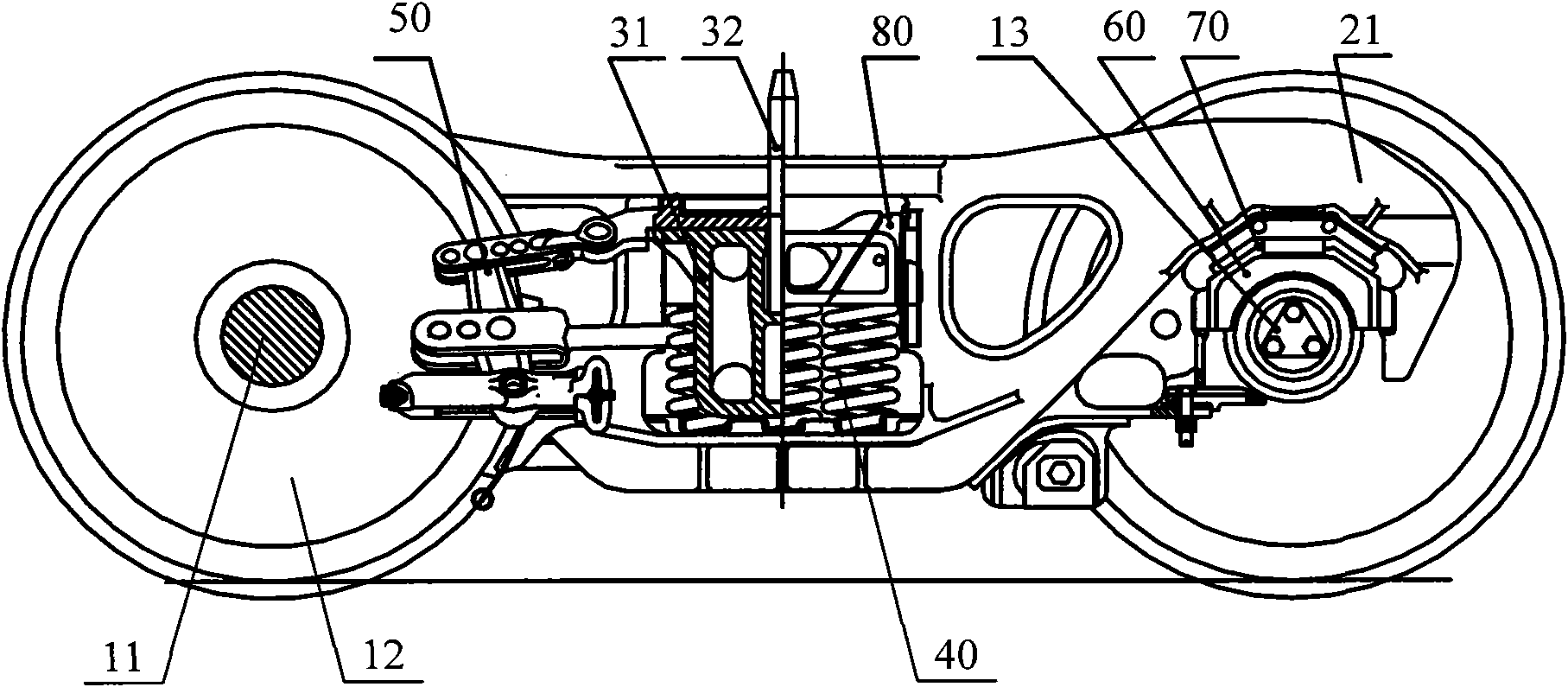

[0055] image 3 It is a schematic diagram of a semi-sectional structure of a bogie provided in Embodiment 1 of the present invention, Figure 4 for image 3 Schematic diagram of the side half-section structure of the middle bogie, Figure 5 for image 3 Schematic diagram of the top view structure of the middle bogie. Such as image 3 , 4 As shown in and 5, the bogie of this embodiment mainly includes a wheel set composition, a side frame composition, a bolster composition, a foundation braking device 50 and a vibration damping device 40, each structure will be described in detail below.

[0056] The wheelset consists of two axles 11 and their wheels 12 . Such as Figure 5 As shown, the side frame composition includes two side frames 21 respectively arranged on both sides of the wheel 12 . Two ends of each side frame 21 are respectively overlapped on the wheel shaft 11 , so that the wheel shaft 11 bears the side frame 21 and the load on the side frame 21 . At the joint...

Embodiment 2

[0061] Figure 6 The partial structural schematic diagram of the bogie provided by Embodiment 2 of the present invention specifically shows the structure at the rubber pad of the axle box. The bogie of this embodiment can further optimize and improve the axle box rubber pad based on the above bogie structure. Such as Figure 6 As shown, the axle box rubber pad is sandwiched between the side frame 21 and the bearing saddle 60, and the axle box rubber pad specifically includes a longitudinal support portion 71 and a lateral positioning portion 72; the lateral positioning portion 72 is along the longitudinal support portion 71 The longitudinal direction is set on the side of the longitudinal support part 71, and there is an included angle between the longitudinal support part 71 and the transverse positioning part 72, the included angle is greater than zero, as long as there is a certain bending relative to the longitudinal support part 71, it can To the lateral positioning eff...

Embodiment 3

[0068] Figure 7 The structure schematic diagram of the axle box rubber pad in the bogie provided by the third embodiment of the present invention, this embodiment can be based on the second embodiment, and the structural realization of the axle box rubber pad with the above shape is preferably: the axle box rubber pad Both the longitudinal support portion 71 and the lateral positioning portion 72 include an upper liner 75 and a lower liner 76 , and a rubber layer 77 is arranged between the upper liner 75 and the lower liner 76 . That is, the axle box rubber pad 70 is formed by interposing a rubber layer 77 between liners.

[0069] In this embodiment, specifically, a boss 73 may be provided on the upper liner 75 and the lower liner 76 , so as to rigidly engage with the bearing saddle 60 and the groove 74 of the side frame 21 . The upper liner 75 is in contact with the side frame 21 and bears the weight from the parts above the side frame 21. The lower liner 76 is closely atta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com