Method of machine tool calibration

A technology for machine tools and rotating parts, used in milling lathes, calibration lathes such as lathes, and can solve problems such as unacceptable time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

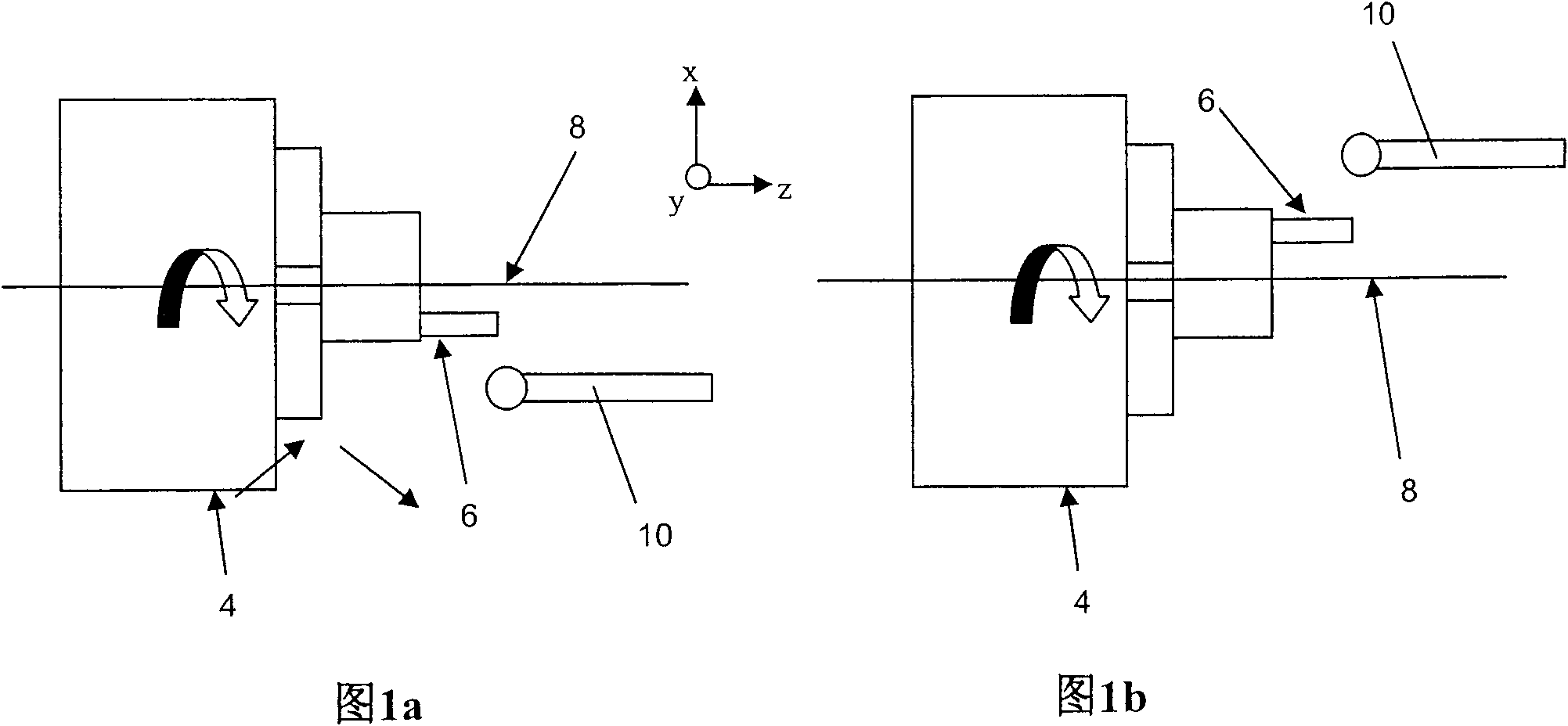

[0083] Referring to FIG. 1 , a plan view of a lathe chuck 4 is shown, with features 6 . Feature 6 may be an integral feature formed in or on the chuck or may be formed in a part held by the chuck. Also shown is an associated measurement probe 10, such as a touch trigger probe of the kind described in EP0283486. Such probes are typically mountable on a lathe (not shown) tool holder and are interchangeable with one or more cutting tools.

[0084] The chuck 4 is rotatable about an axis of rotation 8, commonly referred to as the lathe centerline or C-axis.

[0085] Figure 1a Illustrates the chuck 4 in a first orientation, while Figure 1b A second orientation is shown in which the chuck 4 is turned by 180° relative to the first orientation.

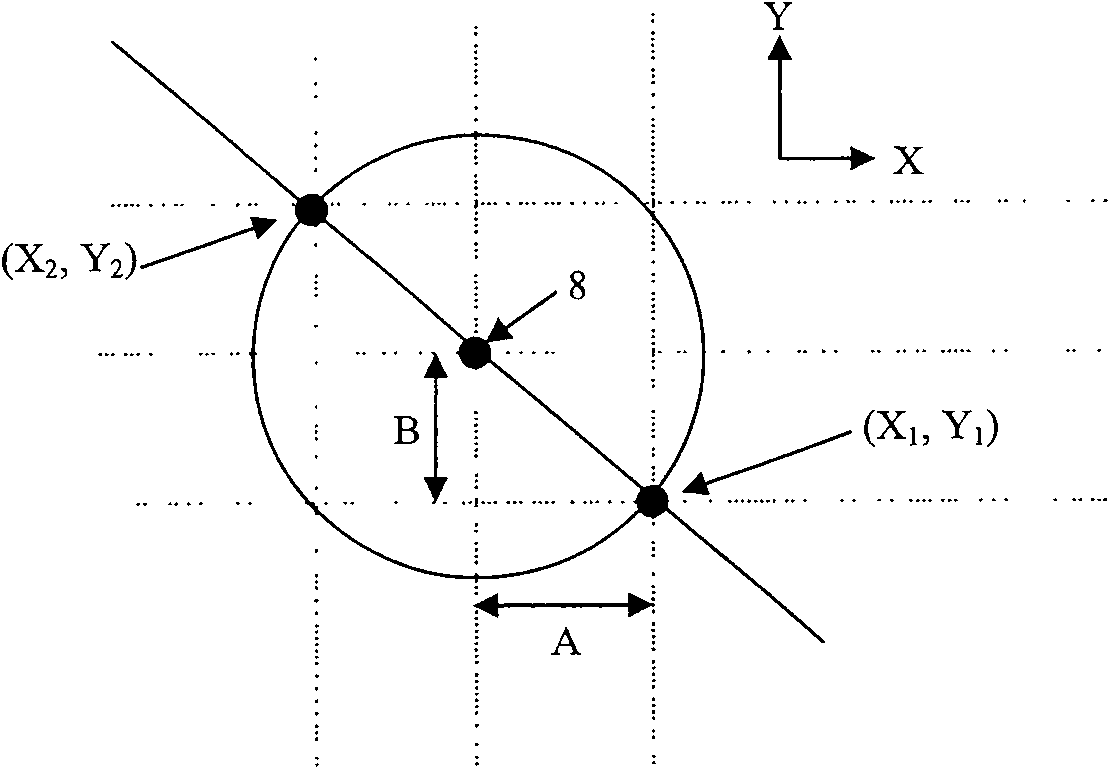

[0086] As mentioned above, the lathe centerline (ie, the axis of rotation of the chuck) must be accurately determined to ensure that the part can be accurately turned to the desired diameter. In order to determine precisely the axis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com