Grids for sintering pallet

A technology for sintering trolleys and grates, which is applied in the structural field of sintering trolleys and grates for metallurgical machinery. It can solve problems such as increasing production costs and affecting production efficiency, so as to prolong service life, improve production efficiency, and reduce U-turns. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

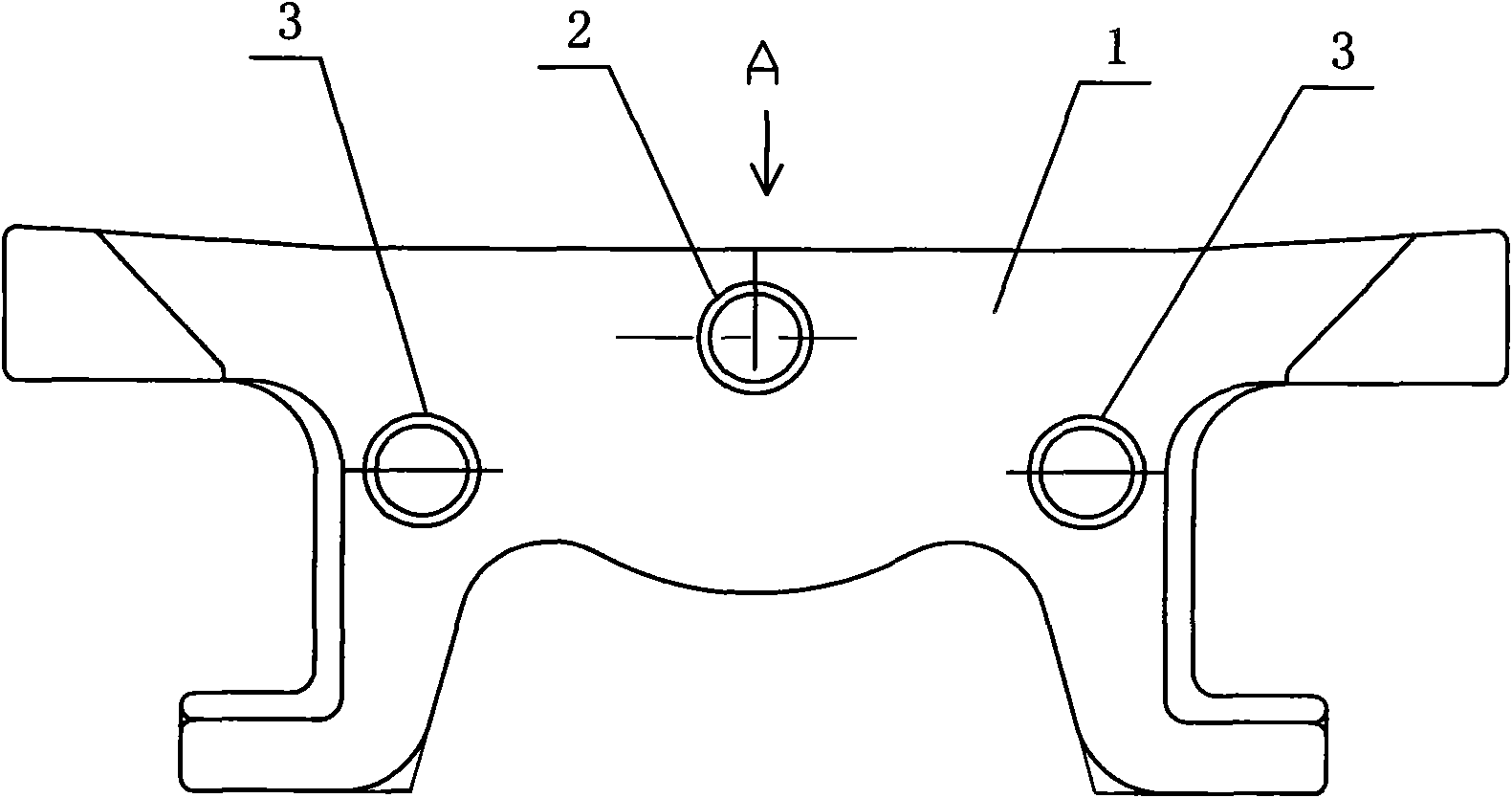

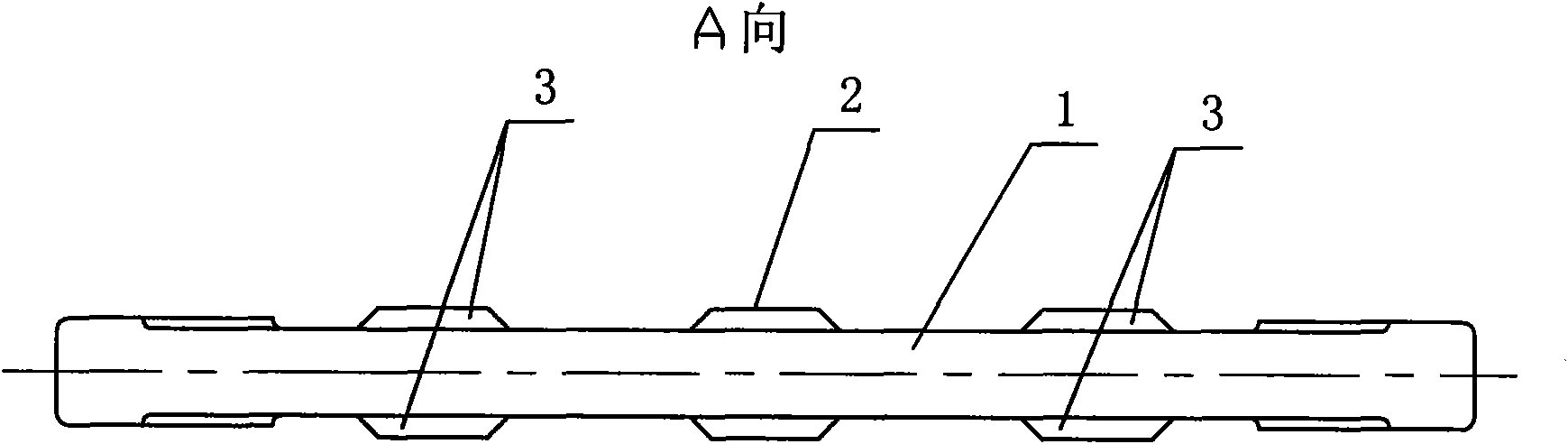

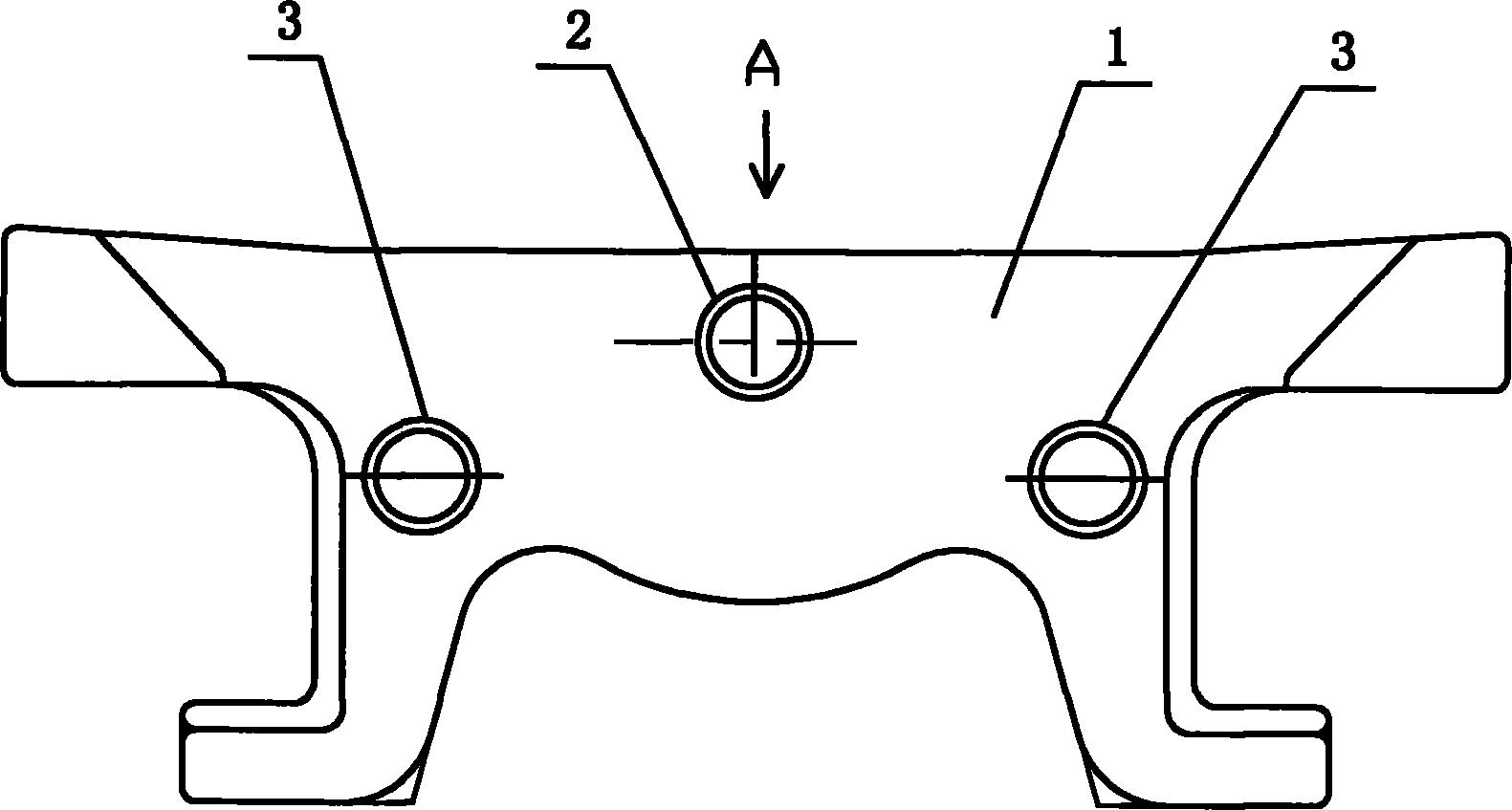

[0009] Such as figure 1 , 2 As shown, it is a grate bar for a sintering trolley, including a grate bar body 1, the two sides of the grate bar body 1 are respectively fixedly connected with the first bosses 2, and the two sides of each first boss 2 are respectively provided with second Bosses 3 , each second boss 3 is fixedly connected with the grate body 1 respectively, and the central horizontal line of each second boss 3 on the same side is lower than the central horizontal line of the first boss 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com