Environmental-friendly pavement regeneration treatment equipment

An environmentally friendly and well-equipped technology, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of reducing the service life of the shot blasting machine, severe blows, and increased steel sand blow loss, so as to reduce and increase the difficulty of turning around and transitioning Long service life and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with embodiment, further illustrate the present invention.

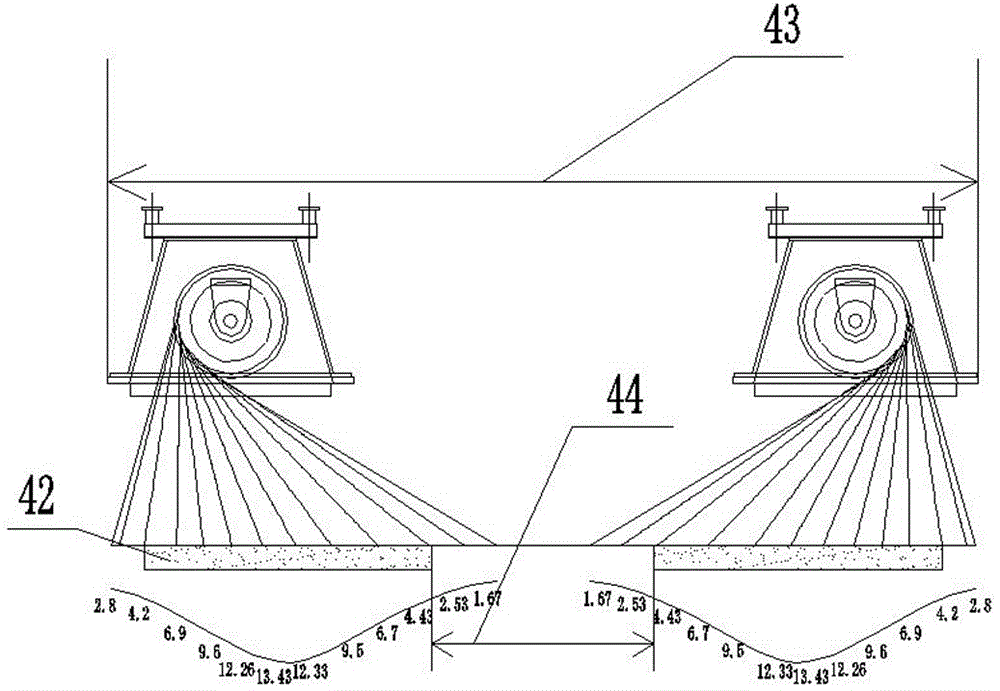

[0041] image 3 , Figure 4 , Figure 5 It is a schematic diagram of the main frame 43 of the road surface regeneration treatment equipment in the prior art, the corresponding shot blaster and its hot zone 42, the hot zone interval 44 and the severe interference zone 45 of the steel shot flow.

[0042] see image 3 , the road surface anti-skid ability recovery engineering vehicle shot blasting device is equipped with two shot blasting devices on the left and right. The angle between the shot blasting device and the road surface is 90 degrees. The treatment of the working surface is uneven. , the area of the shot blasting hot zone is small, the treatment is frivolous, and the uniform regeneration effect of the road surface cannot be achieved, because the shot blasting machine is at a 90-degree angle to the road surface, and the steel grit hits the rebound on the road surface, which wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com