Rough yarn conveying device

A transportation device and roving technology, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of easily damaged workshop floor, increase production cost, wrong position of roving, etc., so as to avoid fuzzing, occupy less space, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make those skilled in the art understand, the present invention will be further described below in conjunction with the accompanying drawings.

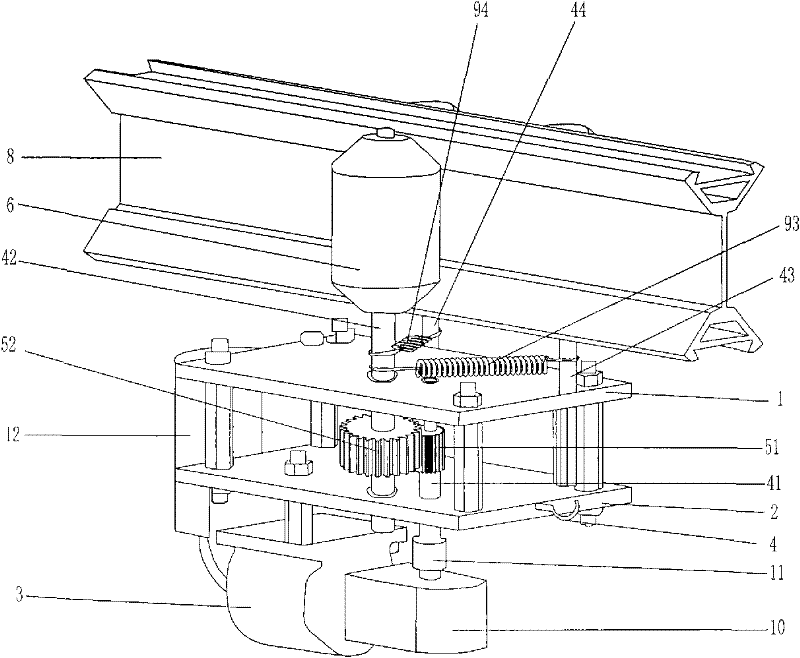

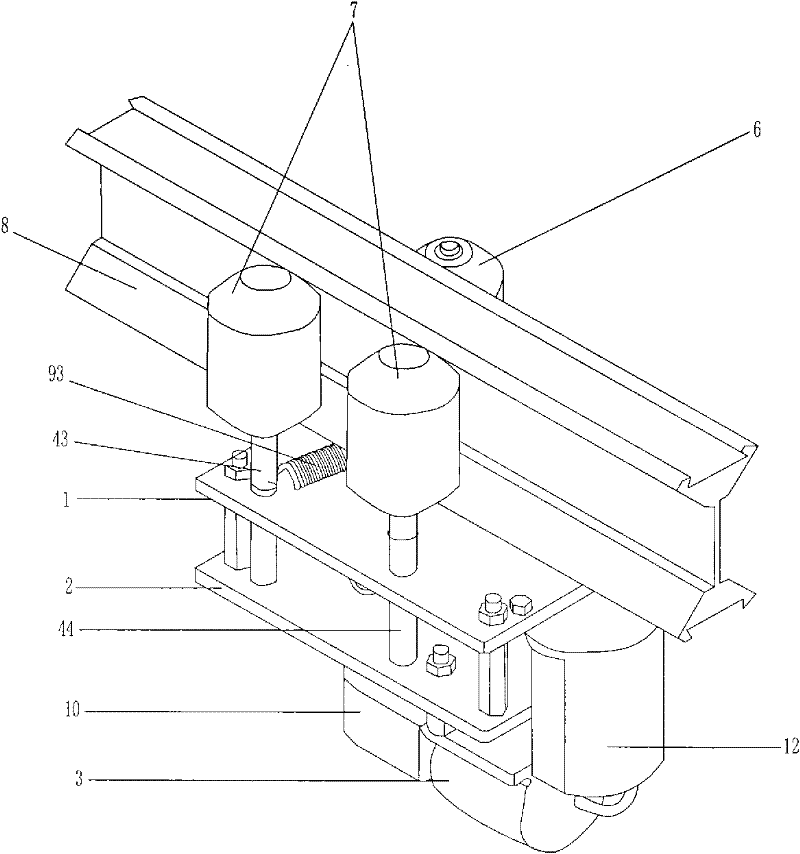

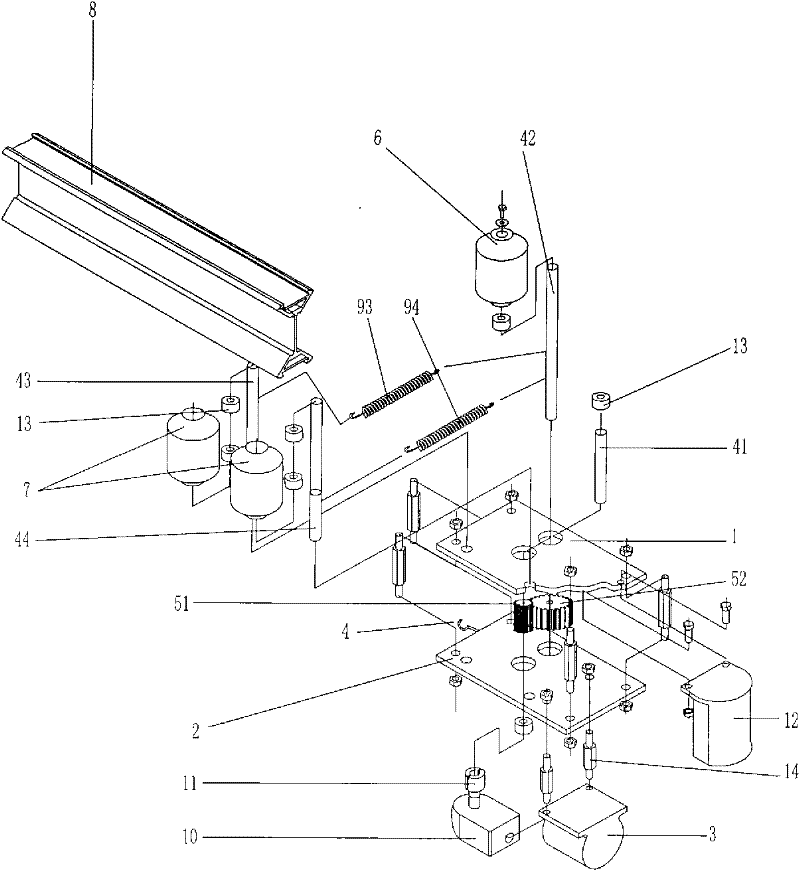

[0013] as attached figure 1 , 2 As shown in , 3, a kind of roving conveying device comprises the upper frame plate 1 and the lower frame plate 2 fixedly attached to each other, the upper frame plate 1 and the lower frame plate 2 are fixedly connected by connecting columns, and also includes a fixed The motor 3 that is installed on the bottom surface of the lower frame plate 2 and the transmission mechanism that is connected with the motor 3, and the track 8 that is connected with the transmission mechanism that is located at the upper frame plate 1 top. This transmission mechanism comprises driving transmission shaft 41, passive transmission shaft 42 and the driving gear 51 and the driven gear 52 that are positioned between upper frame plate 1 and lower frame plate 2, and the lower end of main transmission shaft 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com