Device for automatically expanding and punching pipe fittings

A technology for punching devices and pipe fittings, applied in positioning devices, metal processing mechanical parts, clamping and other directions, can solve the problems of needing manual intervention and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

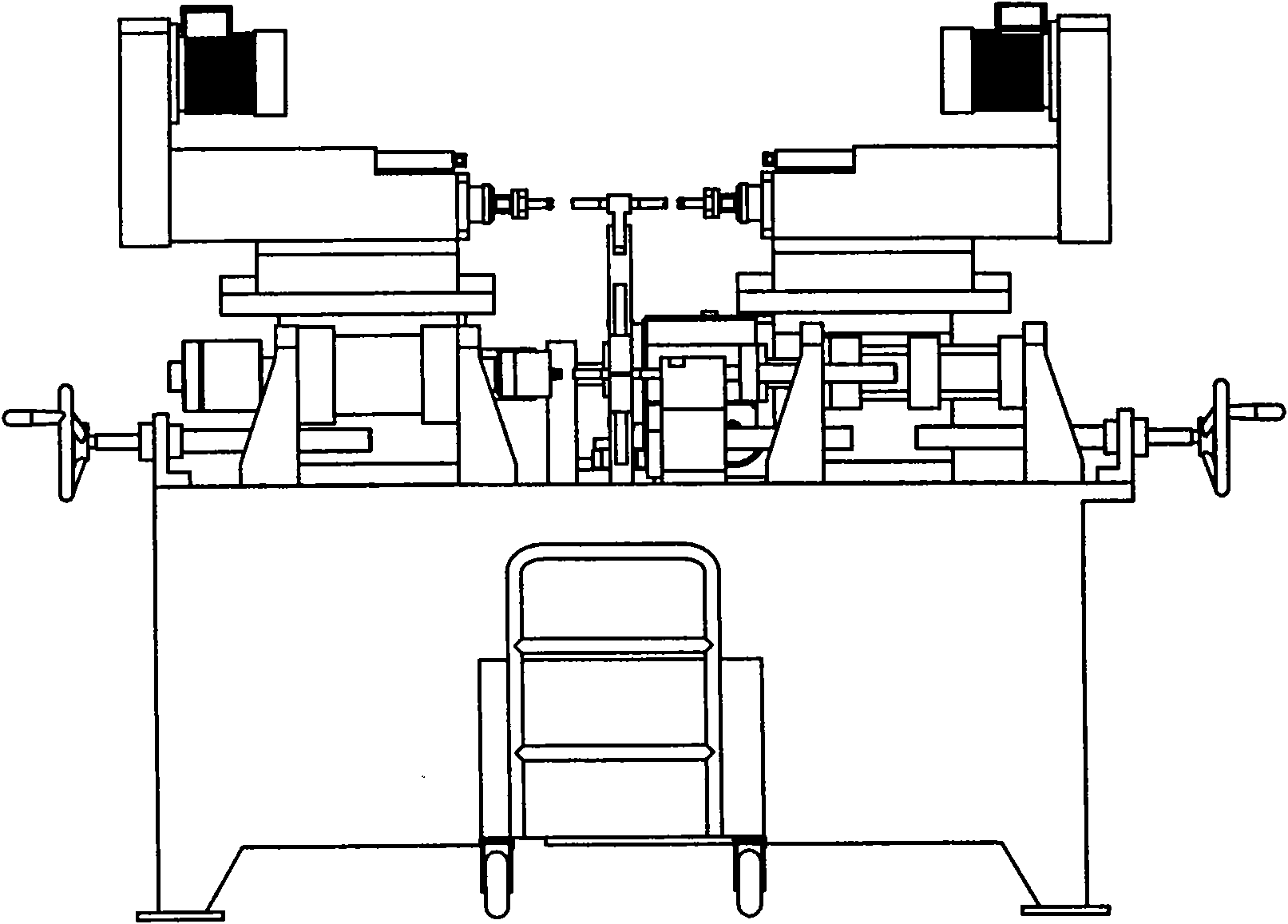

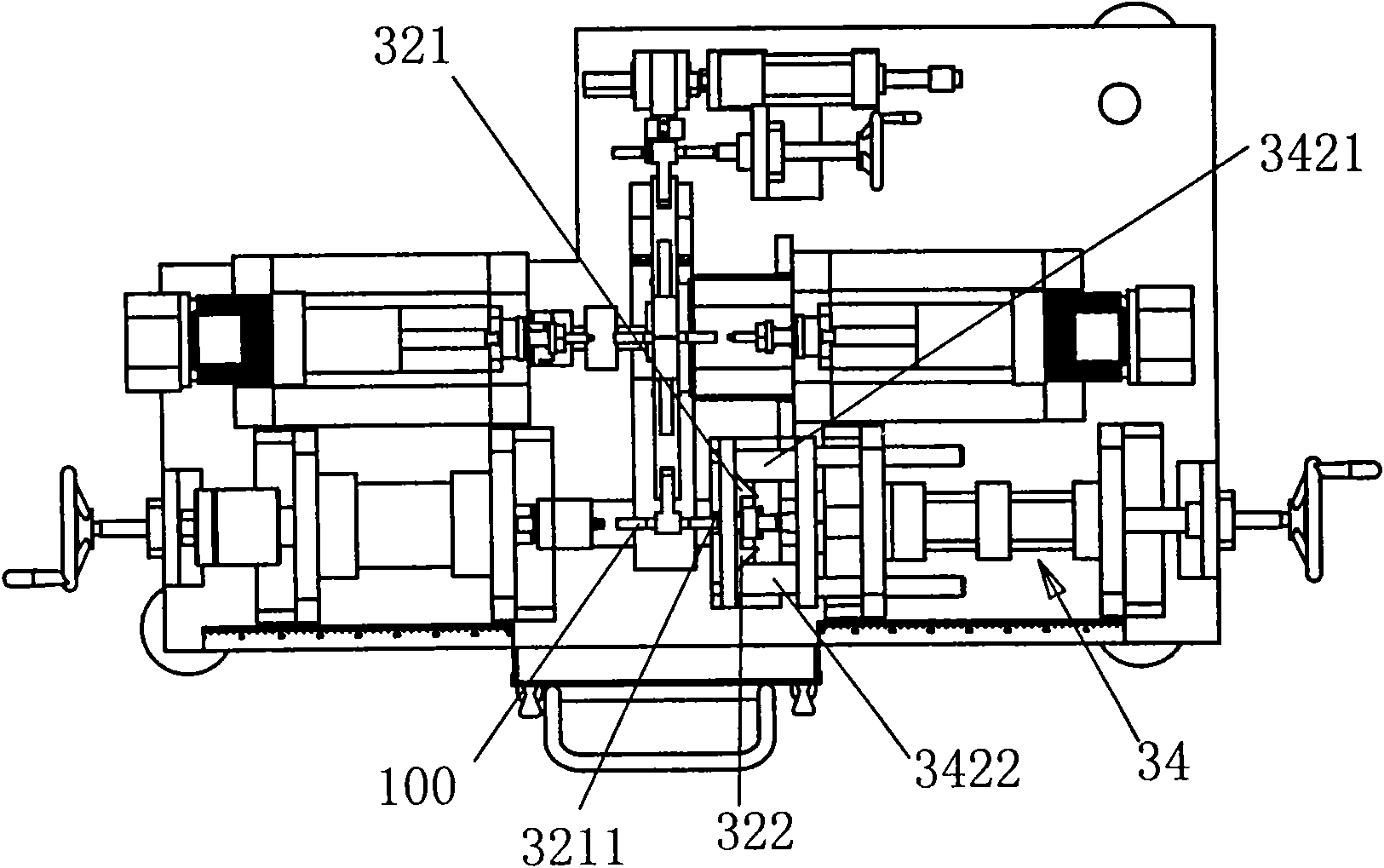

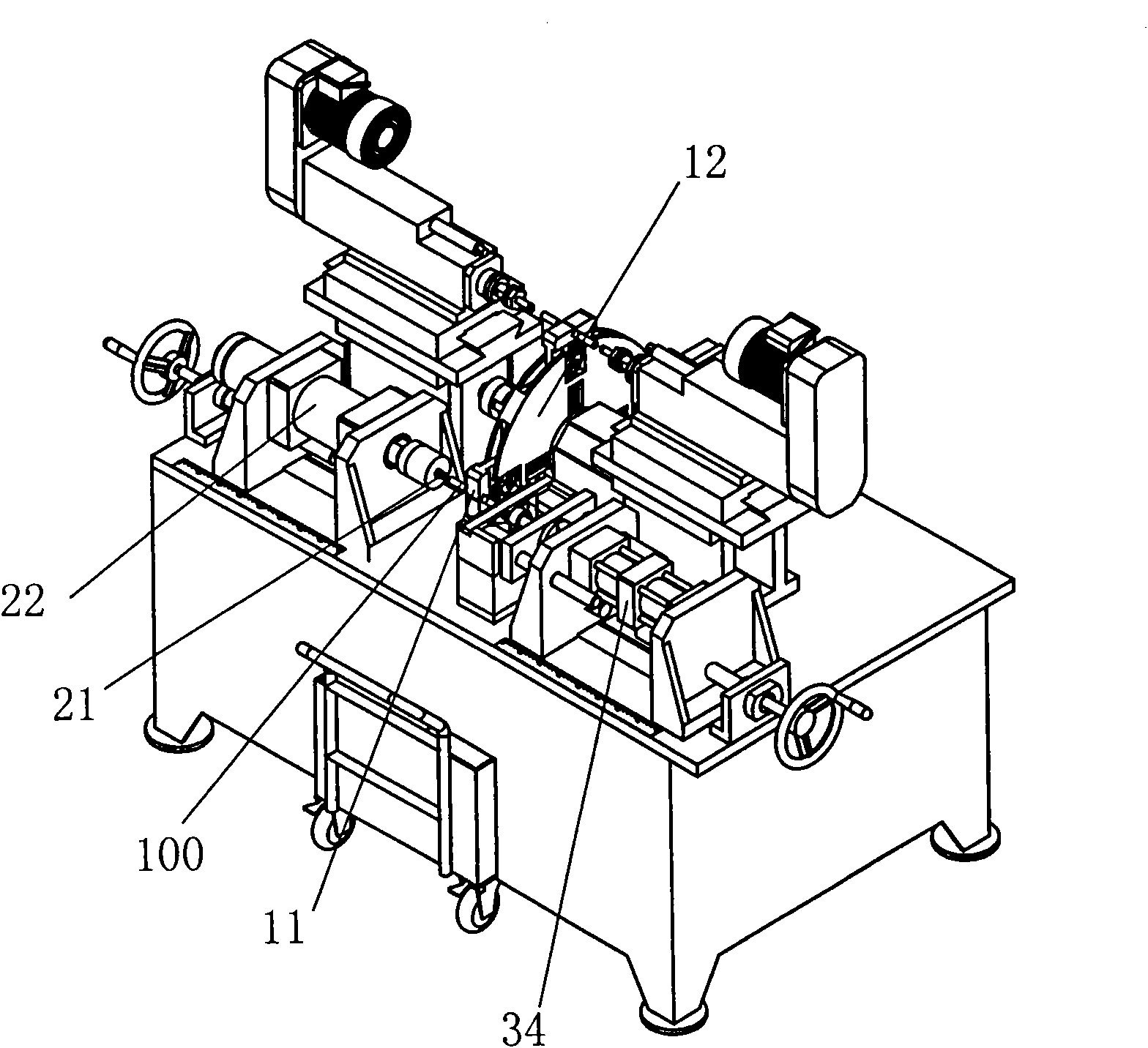

[0018] combine figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , as further described below:

[0019] An automatic pipe expansion and punching device for pipe fittings, comprising a clamping mechanism for clamping and fixing the middle part of the pipe fittings, and a pipe expansion mechanism and a punching mechanism respectively arranged on both sides of the clamping mechanism, wherein:

[0020] 1) The clamping mechanism has a pair of clamping molds 11 for clamping and fixing the pipe fitting 100, the pair of clamping molds 11 are arranged on the rotating disk 12, and are rotated and transposed by controlling the rotating disk;

[0021] 2) The pipe expansion mechanism includes a pipe expansion die 21 and a pipe expansion cylinder 22 that drives the pipe expansion die to expand the pipe opening. And adjust the distance between the handwheel and the clamping mechanism;

[0022] 3) The punching mechanism includes a piercing die, a pair of fixed blocks (321, 322)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com