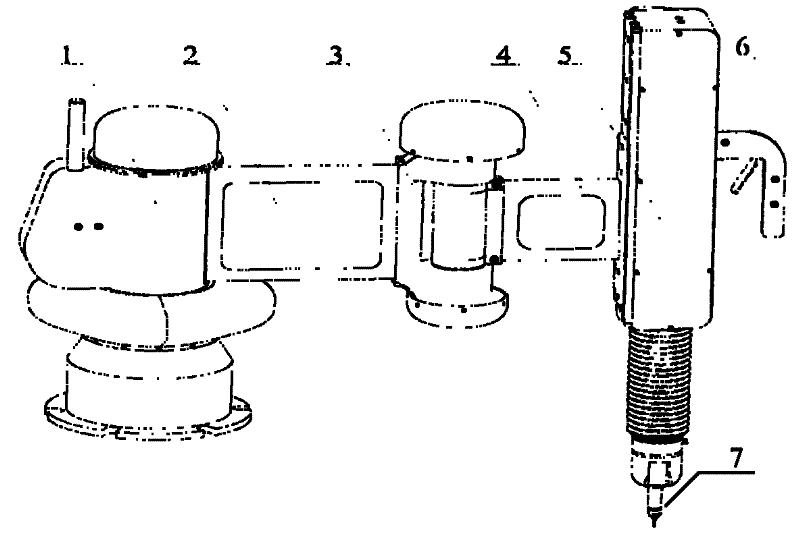

Method for calibrating lengths of connecting rods of parallel double-joint coordinate measuring machine

A technology of a coordinate measuring machine and a calibration method, which is applied in the direction of measuring devices and instruments, and can solve the problems of many error terms and low precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The purpose of the present invention is to provide a set of technology for calibrating the length of the connecting rod of the parallel double-joint coordinate measuring machine, and improve the calibration accuracy of the length of the connecting rod of the parallel double-joint coordinate measuring machine.

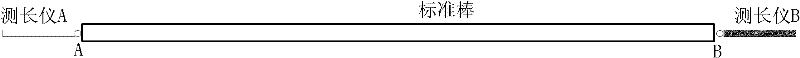

[0039] In order to solve the error problem, the present invention proposes a set of experimental methods for calibrating the length of the connecting rods of the parallel double-joint coordinate measuring machine. Some rods are fixed, and the undetermined parameters are calibrated step by step. Effectively calibrate the system error parameters of the instrument.

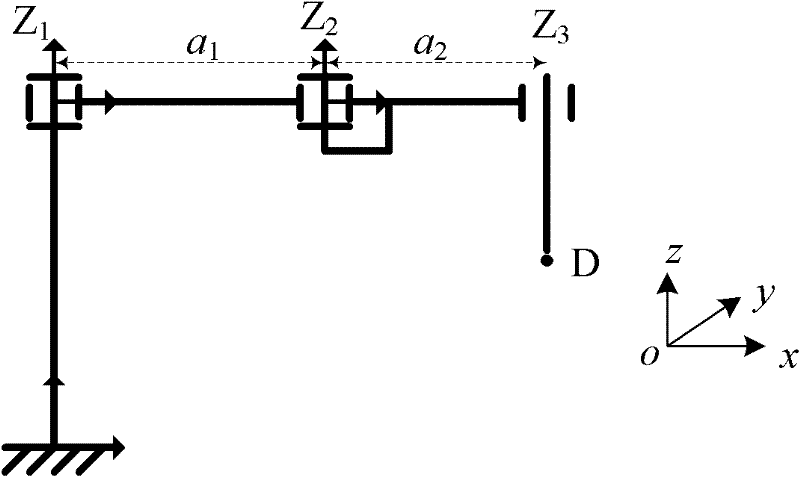

[0040] There are two aspects in the length calibration of the connecting rod of the parallel double-joint coordinate measuring machine:

[0041] 1. Connect the axis of rotation Z 2 with linear joint Z 3 The small connecting rod a 2 The length calibration.

[0042] 2. Connect the axis of rotation Z ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com