Method for polishing semiconductor wafer

A semiconductor and wafer technology, applied in the field of double-sided polishing of semiconductor wafers, can solve problems such as unfavorable polishing machines and wafer fixing systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

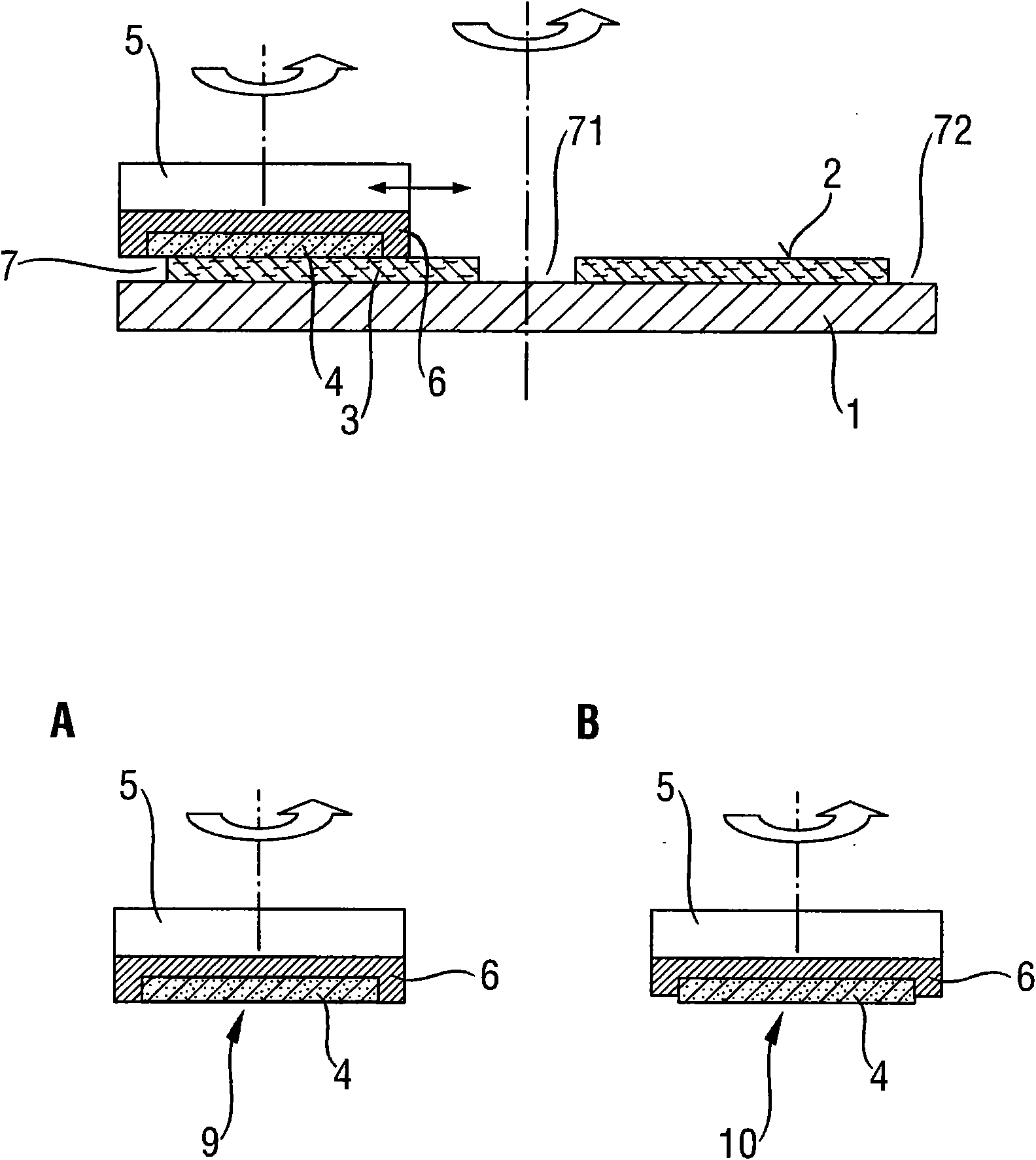

[0110] All polishing processes presented below were carried out using monolithic supports (no membrane supports, no multi-region supports) equipped with templates.

[0111] The carrier substrate itself may have a planar, convex or concave shape.

[0112] A 3-plate polisher such as AMAT Reflection from Applied Materials, Inc. was used as the polisher.

[0113] A. Polishing the backside of a semiconductor wafer with workpiece offset:

[0114] An FA polishing pad with an average abrasive grain size of 0.5 μm was used. Abrasive-free polishing compounds such as dilute K are available 2 CO 3 .

[0115] A second partial polishing step of the backside of the semiconductor wafer is optionally carried out on the same polishing pad, but with a supply of silica sol, eg Glanzox 3900, in order to adjust the roughness of the backside of the wafer in a targeted manner.

[0116] B. Polishing the front side of the semiconductor wafer in three steps:

[0117] B.1. Plate 1 equipped with a F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com