Pipe composite-motion driving device

A technology of compound motion and driving device, applied in the direction of mechanical thickness measurement, can solve the problems of low efficiency, difficulty in finding the minimum value of wall thickness, and inability to achieve continuous measurement, and achieve the effect of improving accuracy and work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

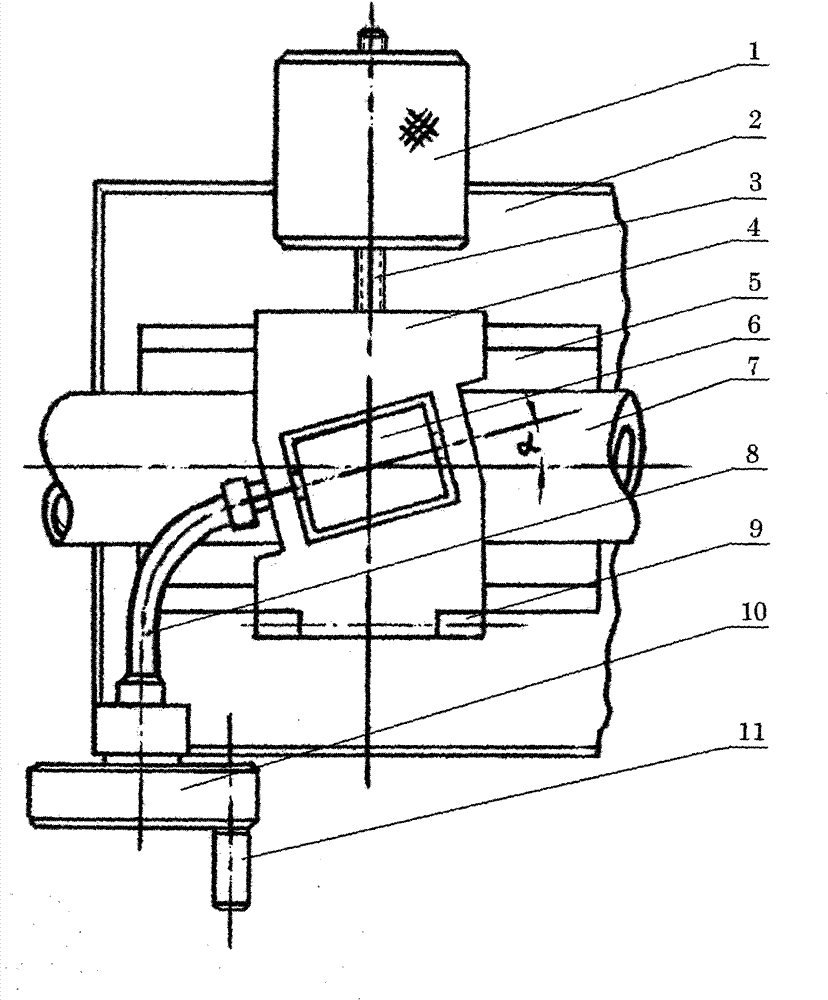

[0014] Such as figure 1 The shown pipe compound motion drive device includes a base 2 , a V-shaped support 5 , and a friction drive wheel 6 . Wherein the V-shaped support 5 is a long groove with a V-shaped cross section and an upward opening, and its bottom is fixed on the base 2 by screws.

[0015] The drive wheel mounting plate 4 is a horizontal plate with a square hole in the middle of the plate. Perforate on the vertical axis direction of square hole inner edge, the axle of friction drive wheel 6 is installed in the hole. An outer edge of the drive wheel mounting plate 4 is hinged to one side top edge of the V-shaped support 5 through a hinge plate 9 . A screw rod perpendicular to the longitudinal axis of the V-shaped support 5 is installed on the other side opposite to the hinged side of the V-shaped support 5 on the drive wheel mounting plate 4 , and a weight 1 is installed on the screw rod 3 . The driving wheel mounting plate 4 can cover the notch of the V-shaped sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com