Device for measuring wall thickness of pipe

A wall thickness measurement and pipe technology, which is applied in the field of analysis and testing of polymer materials, can solve problems such as difficulty in finding the minimum value of wall thickness, difficulty in finding the minimum wall thickness value, and inability to perform continuous measurement, and achieve reliable measurement results, The effect of eliminating measurement errors and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

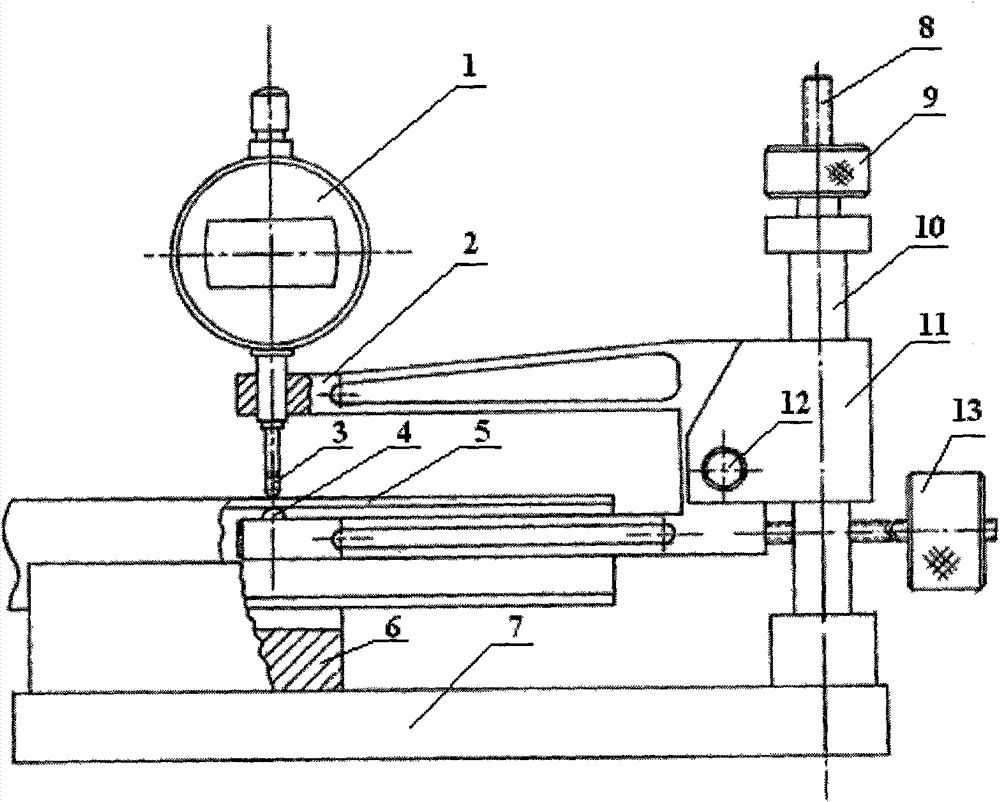

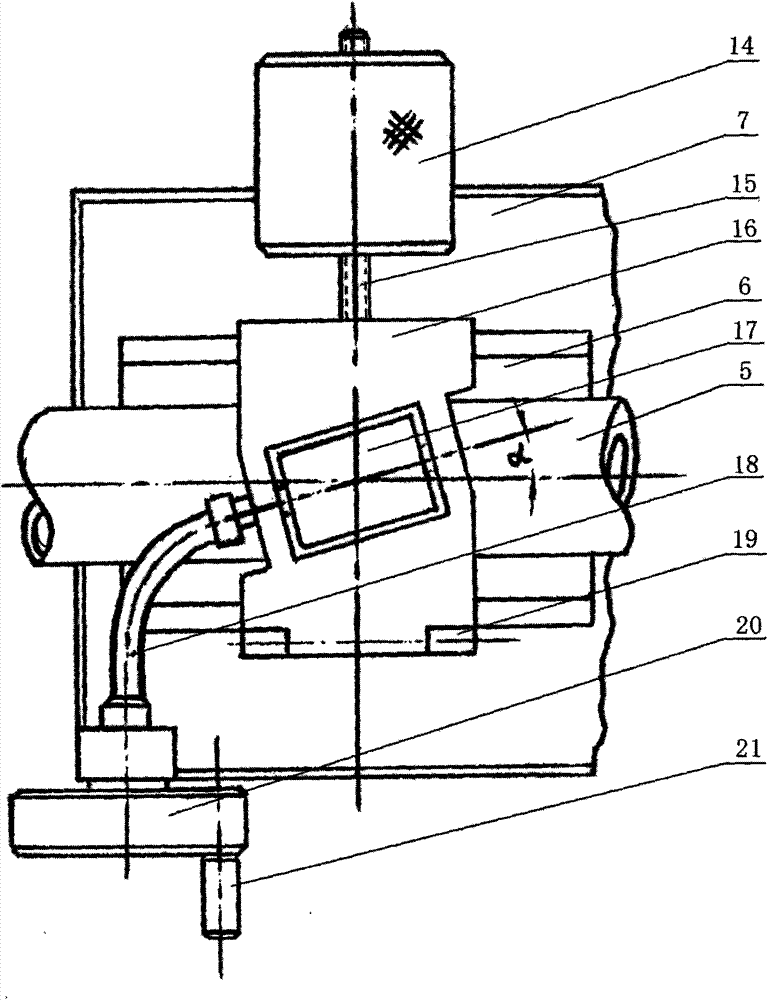

[0021] like figure 1 As shown, the pipe wall thickness measuring device of the present invention includes a dial indicator 1 , a measuring rocker 2 and a base 7 .

[0022] The lower end of the dial gauge 1 is a measuring rod, and the lower end of the measuring rod is equipped with a dial gauge measuring head 3; the measuring rocker arm 2 includes parallel upper arms and lower arms, and one end on the same side of the upper arm and the lower arm is formed by a vertical rod Fixedly connected, the upper surface of the other end of the lower arm is equipped with a fixed measuring head 4, the other end of the upper arm is vertically fixed with the dial indicator 1, the measuring rod of the dial indicator 1 passes through the upper arm of the measuring rocker arm 2, and the dial indicator at the lower end The sub-meter measuring head 3 is aligned with the fixed measuring head 4 on the lower arm. A first screw rod is installed on the backward extension of the lower arm of the measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com