Internal core-pulling mechanism for inclined hole of injection-molded plastic piece

A technology of injection molding plastic and inner core pulling, which is applied in the field of plastic molds to achieve the effects of reducing friction, convenient connection and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

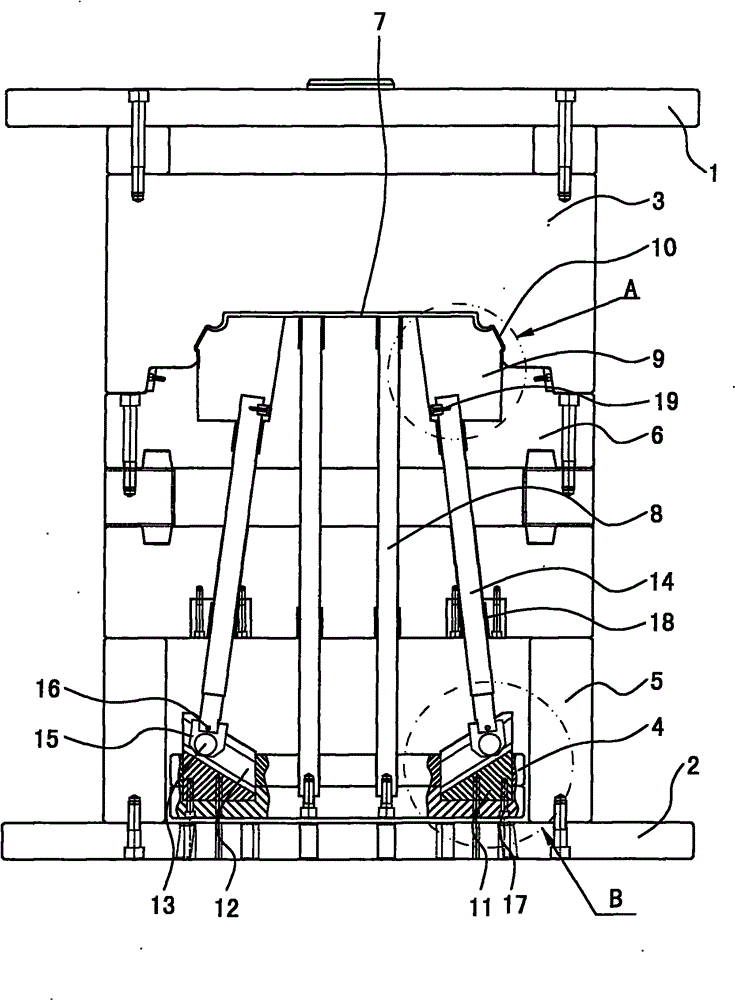

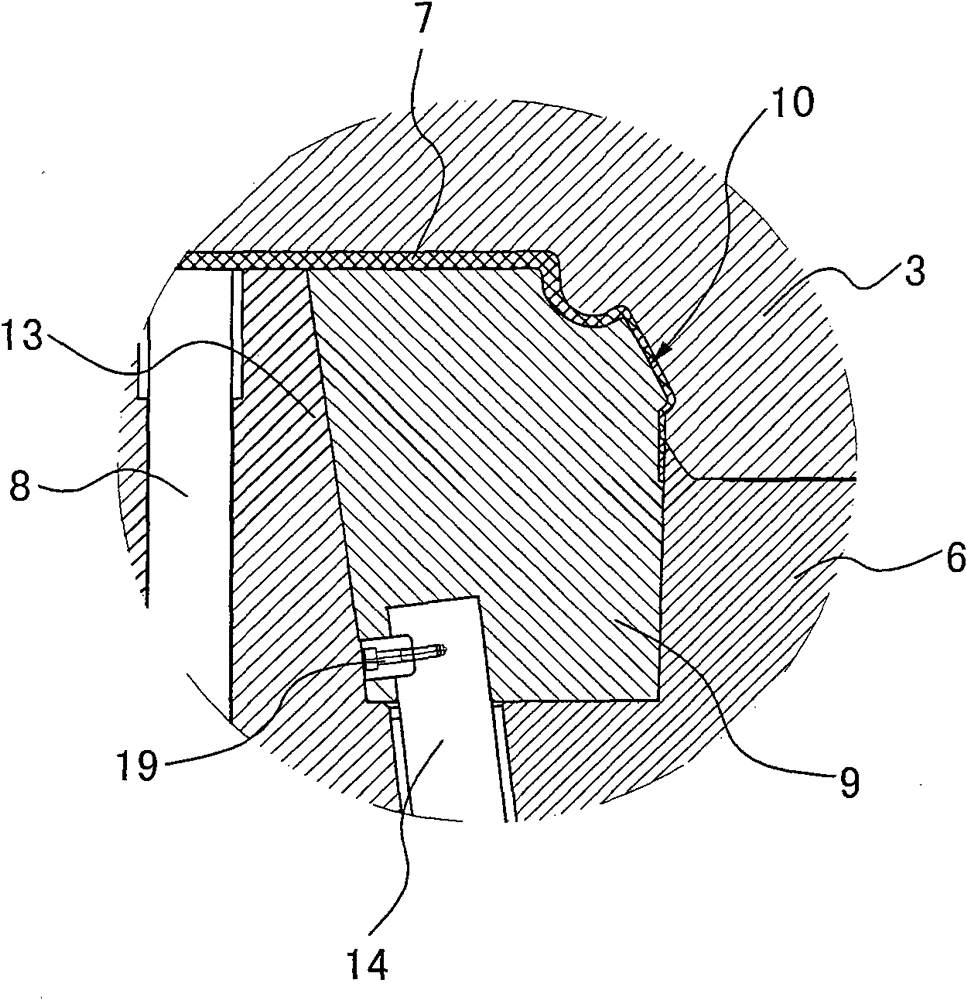

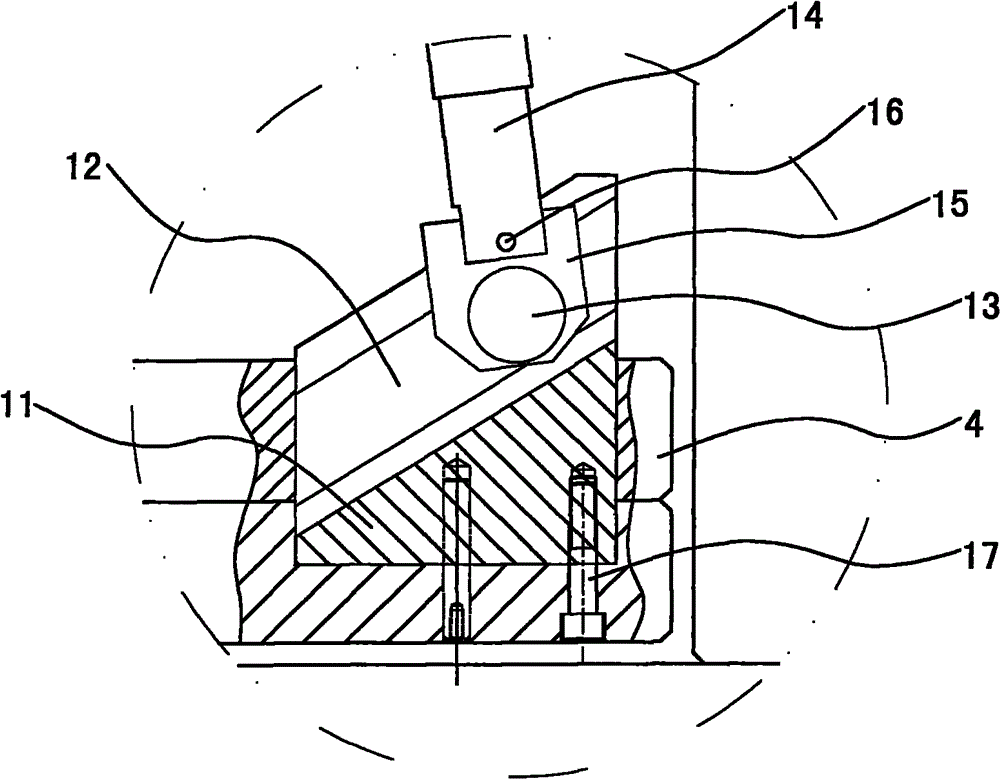

[0010] The invention discloses a core-pulling mechanism in an inclined hole of an injection-molded plastic part, such as Figure 1-Figure 3 As shown, it includes an upper template 1 and a lower template 2, the upper template is connected to the cavity 3, the top plate 4 and the mold foot 5 are installed on the lower template, the core 6 is installed on the mold foot, and the mold cavity is formed between the core and the mold cavity. There is a molded plastic part 7 in the cavity, and a straight ejector rod 8 is installed on the top plate. The straight ejector rod passes through the core 6 and contacts the plastic part. The inner pumping block 9 is installed in the core 6, and the inner pumping block 9 is connected to the inclined hole 10 of the plastic part. Matching, it is characterized in that an inclined slide seat 11 is installed on the top plate 4, an inclined slide groove 12 is formed in the inclined slide seat, a rolling pin 13 is arranged in the inclined slide groove, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com