Patents

Literature

41results about How to "Does not affect cooling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

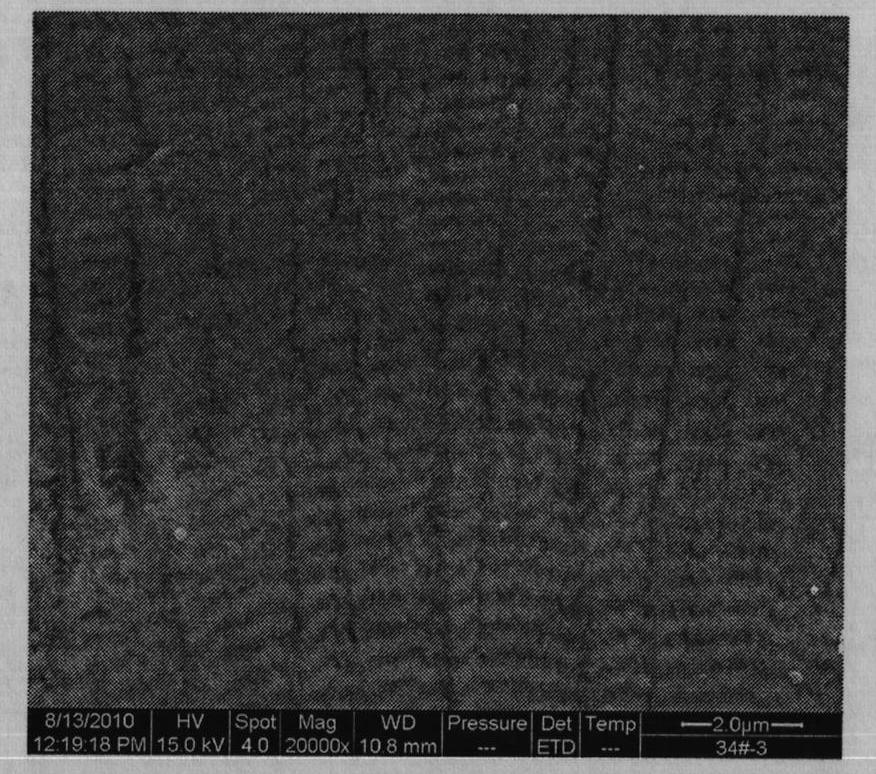

Method for preparing thermal barrier coating

ActiveCN102212786AImprove thermal shock resistanceExtend your lifeVacuum evaporation coatingSputtering coatingBiological activationPhonon

The invention discloses a method for preparing a thermal barrier coating. According to the method disclosed by the invention, a deposition matrix is bombarded by ion beams while a deposition coating is evaporated by electron beams, the steam energy of the electron beams is about 0.1-1 electron volts, and the energy is not enough to well migrate atoms in the process of depositing the coating; and the energy of the ion beams can reach thousands of electron volts, and the energy is enough to interfere growth of columnar crystals to increase crystal boundaries and crystal sub-boundaries and enlarge or increase microscopic holes so as to reduce phonon and photon scattering mean free path and reduce the thermal conductivity of the thermal barrier coating. The energy of vaporous clouds can be increased through activation ionization effects of ions; and compared with the conventional EB-PVD (Electron Beam Physical Vapour Deposition), the method can ensure that same performances can be achieved at low deposition temperature; furthermore, forms, structures and stresses of the columnar crystals can be also adjusted and controlled through ion assisted deposition, and thus, the service life ofthe thermal barrier coating can be prolonged.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

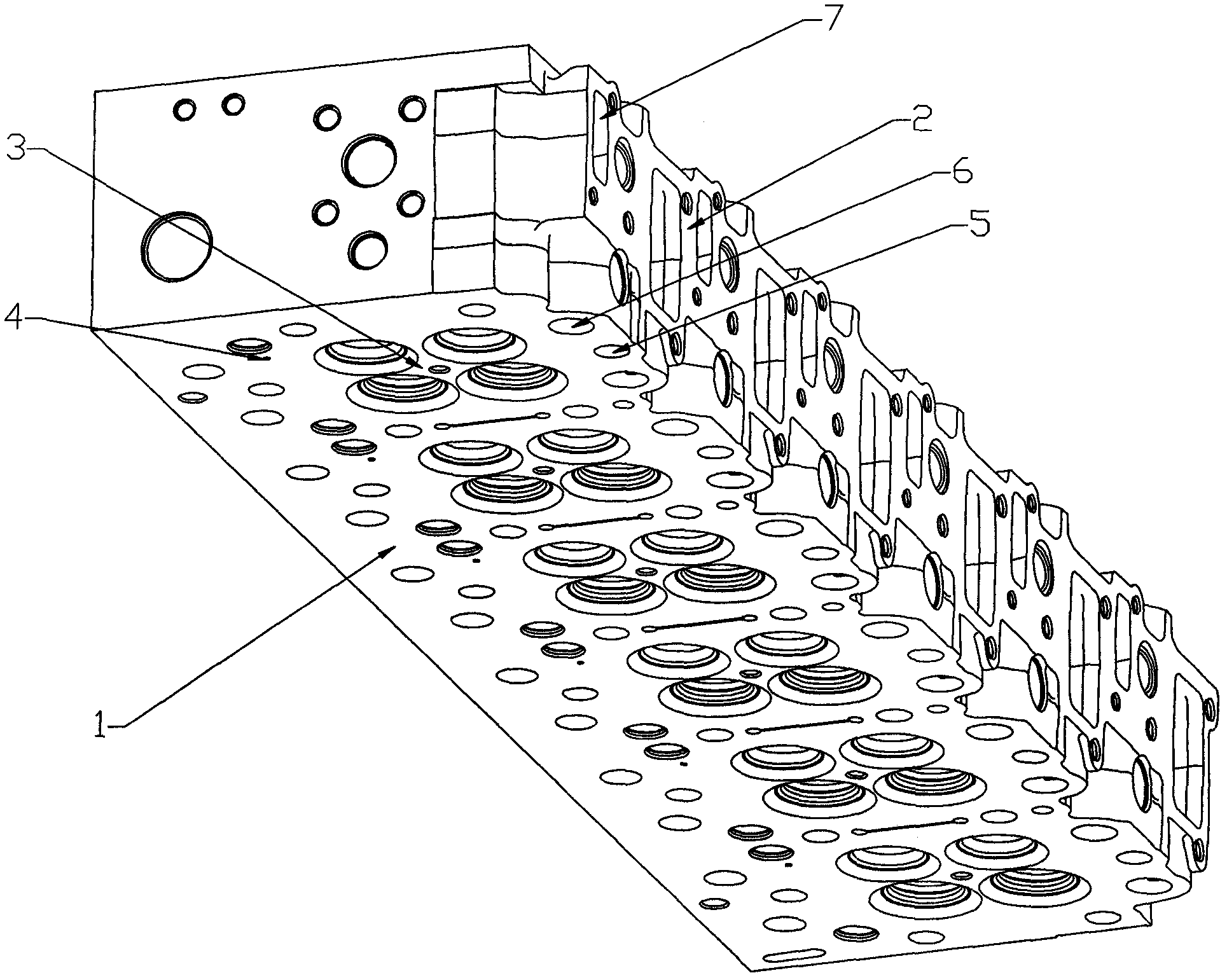

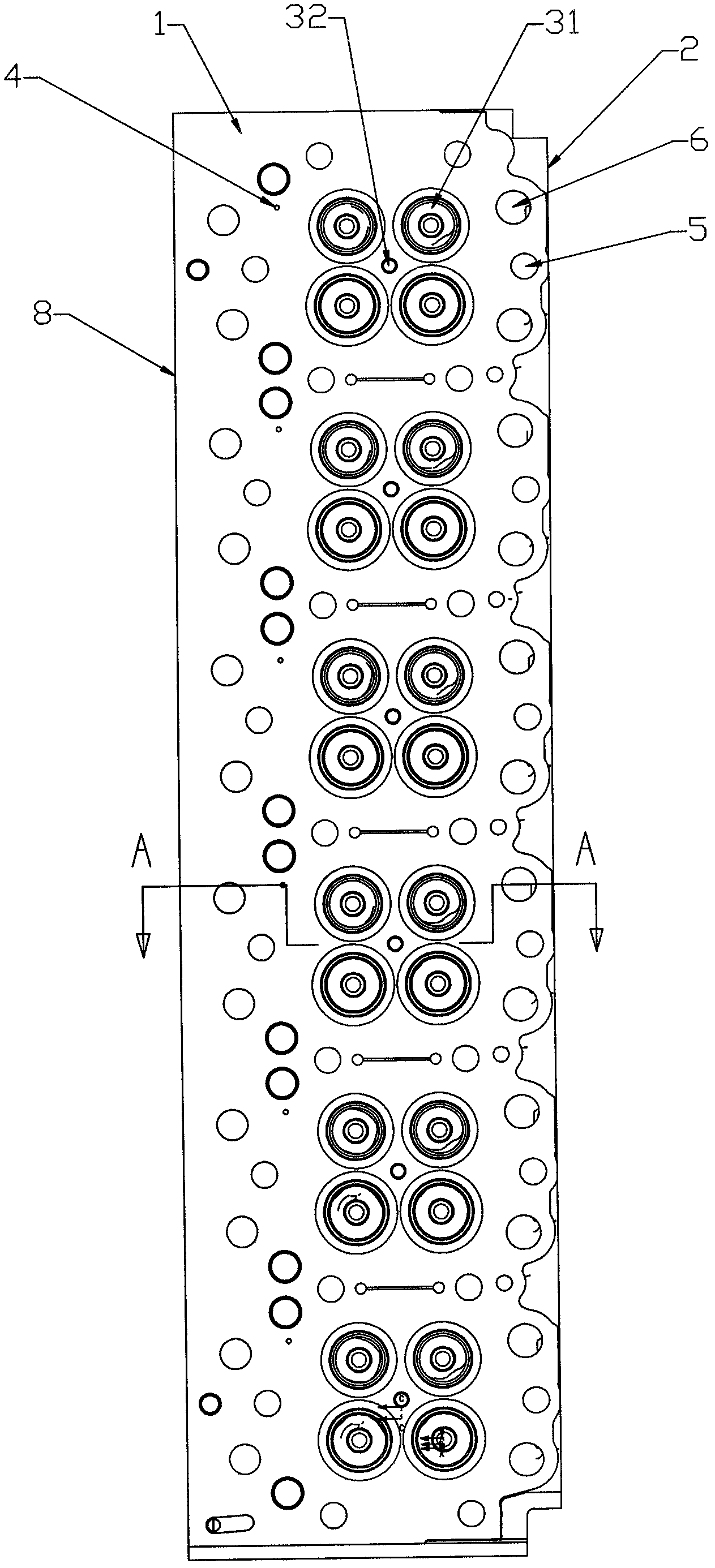

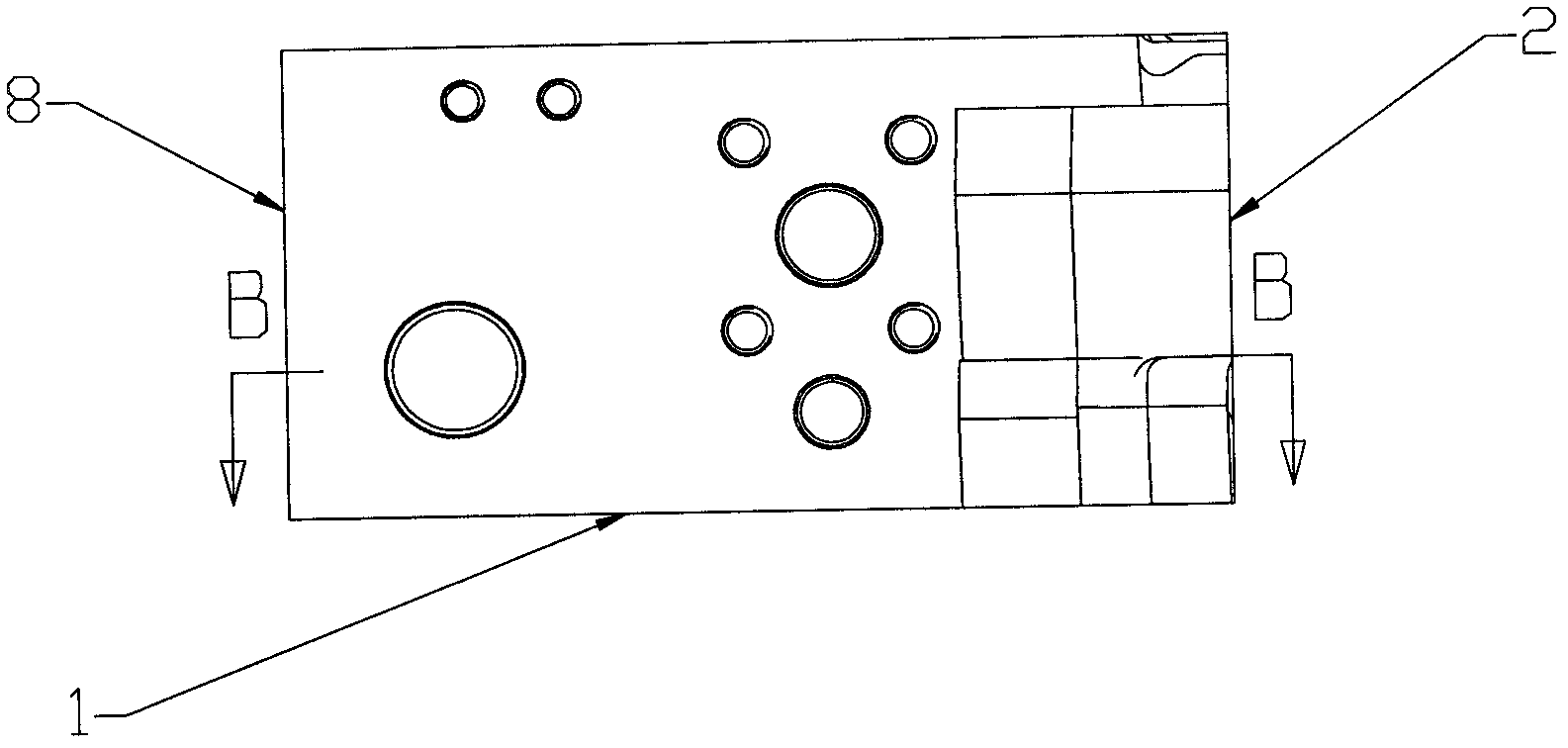

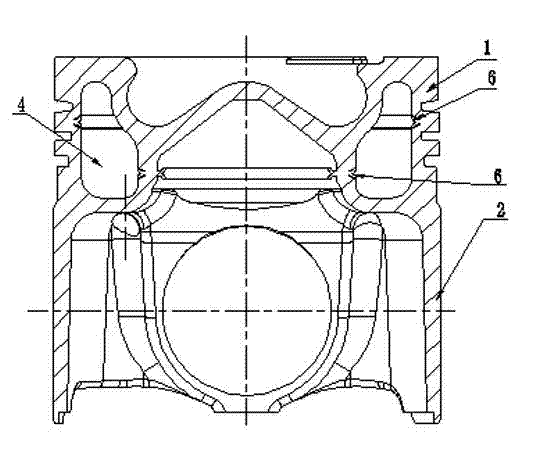

Integral cylinder cover of water-cooled four-valve diesel engine and corresponding diesel engine water cooling method

InactiveCN102758701ANo short circuitImprove cooling effectLiquid coolingCylinder headsCooling effectWater cooling

The invention discloses an integral cylinder cover of a water-cooled four-valve diesel engine and a corresponding diesel engine water cooling method based on the cylinder cover. According to the cylinder cover, a partition plate for partitioning a water cooling cavity into an upper cavity and a lower cavity is arranged in the water cooling cavity, wherein a water feeding passage for communicating the upper cavity and the lower cavity is formed on one side of the partition plate; a bottom plate is provided with an exhaust duct side exhaust hole corresponding to the water feeding passage; and a water inlet hole and an intake duct side exhaust hole which are communicated with the lower cavity are formed on the other side of the bottom plate. The diesel engine water cooling method comprises the following steps of: circulating water cooling outside a diesel engine cylinder from one side to the other side through a circulating water pump; and flowing the cooling water into the lower cavity from the water inlet hole on the bottom plate of the cylinder cover, then flowing to the upper cavity through the water feeding passage from the lower cavity and flowing out from the water outlet. By arranging the partition plate in the cylinder cover, forced cooling water passes through a nose bridge region so as to guarantee a cooling effect of the noise bridge region and the bottom plate of the cylinder cover; and bubbles produced on the outer wall of the cylinder can be quickly washed away and vapor can be discharged, so that cooling water of high water temperature does not easily occur in the diesel engine.

Owner:GUANGXI YUCHAI MASCH CO LTD

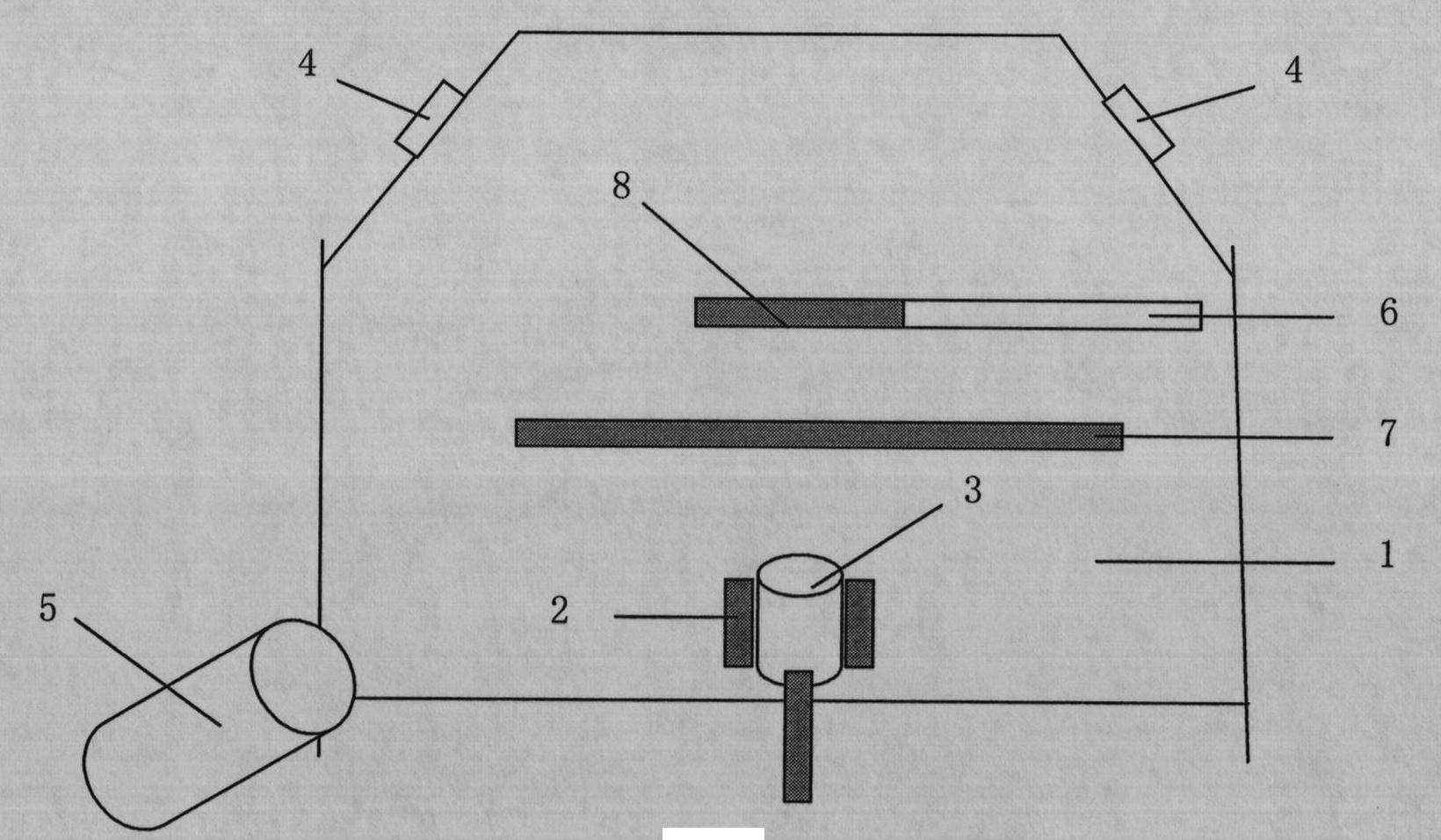

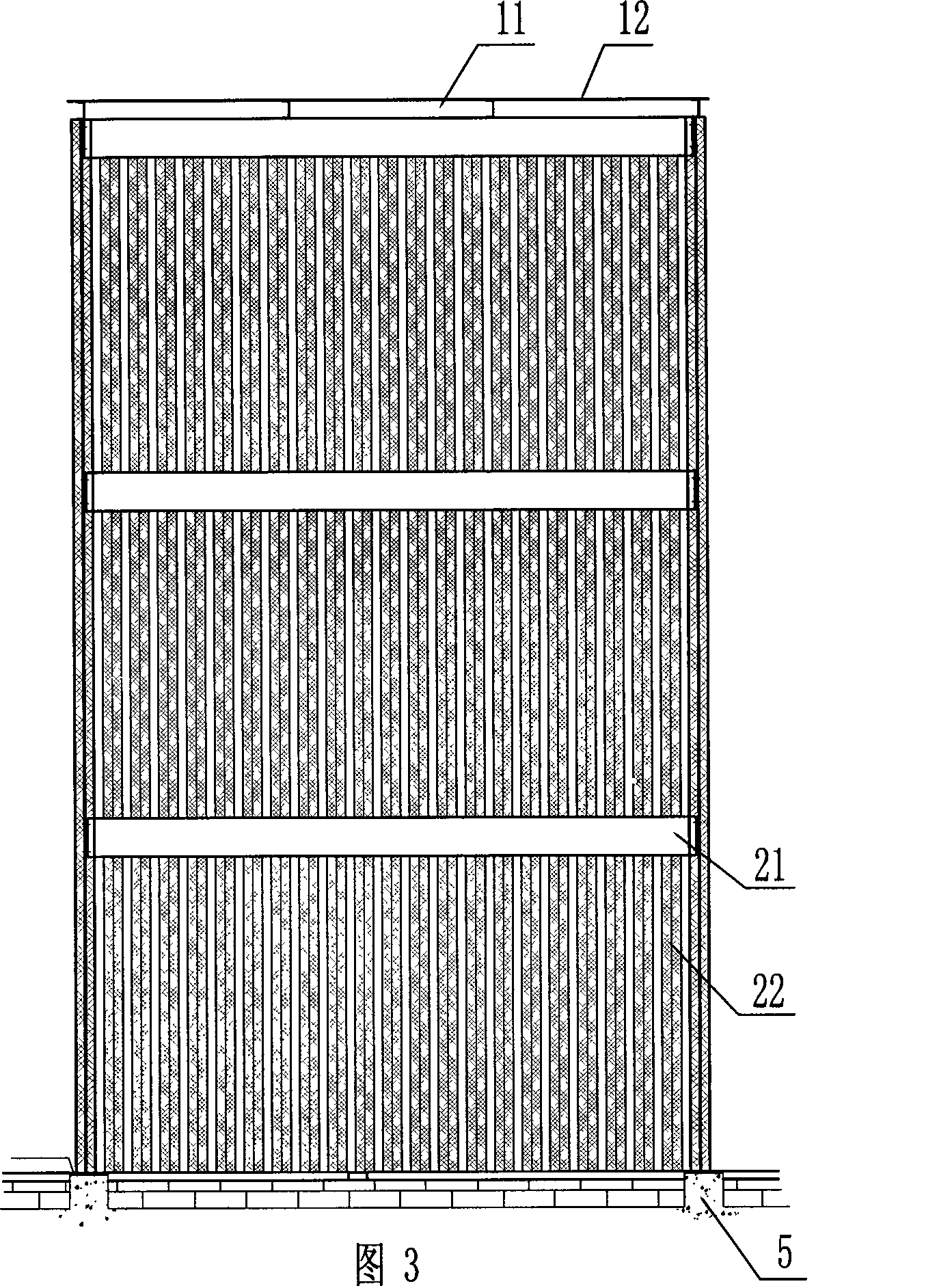

Noise reducing and anti-freezing device outside power plant cooling tower

InactiveCN101377387AStrong sound absorption and noise reduction abilityImprove noise reductionSound producing devicesTrickle coolersCooling towerAnti freezing

The invention provides a noise reducing and antifreezing device used outside a power plant. One of two adjacent noise absorbing plates is fixed with and has an included angle with a horizontal beam, while the other one is arranged in a rotatable way; the cross-sections of the two noise absorbing plates are in a bullet-shape, the effective size of noise absorption is larger, and the gap between the two noise absorbing plates is adjustable, therefore, sound waves produced by a noise source are attenuated repeatedly when passing between the two noise absorbing plates arranged in a slanted way, and the attenuating path is increased; under the conditions of the same distribution density, the effect of noise reduction is more ideal; compared with the prior vertical arrangement proposal, under the same noise reduction conditions, the number of noise absorbing plates adopted by the slanted arrangement proposal of the invention can be reduced by 20 to 40 percent, therefore, the proposal is an ideal proposal to reduce production cost; as the included angle between the two noise absorbing plates is adjustable, the effect of noise reduction can be improved, the cooling tower has antifreezing effect, and the safe and normal operation of the cooling tower in winter is ensured.

Owner:常州金坛塑料厂

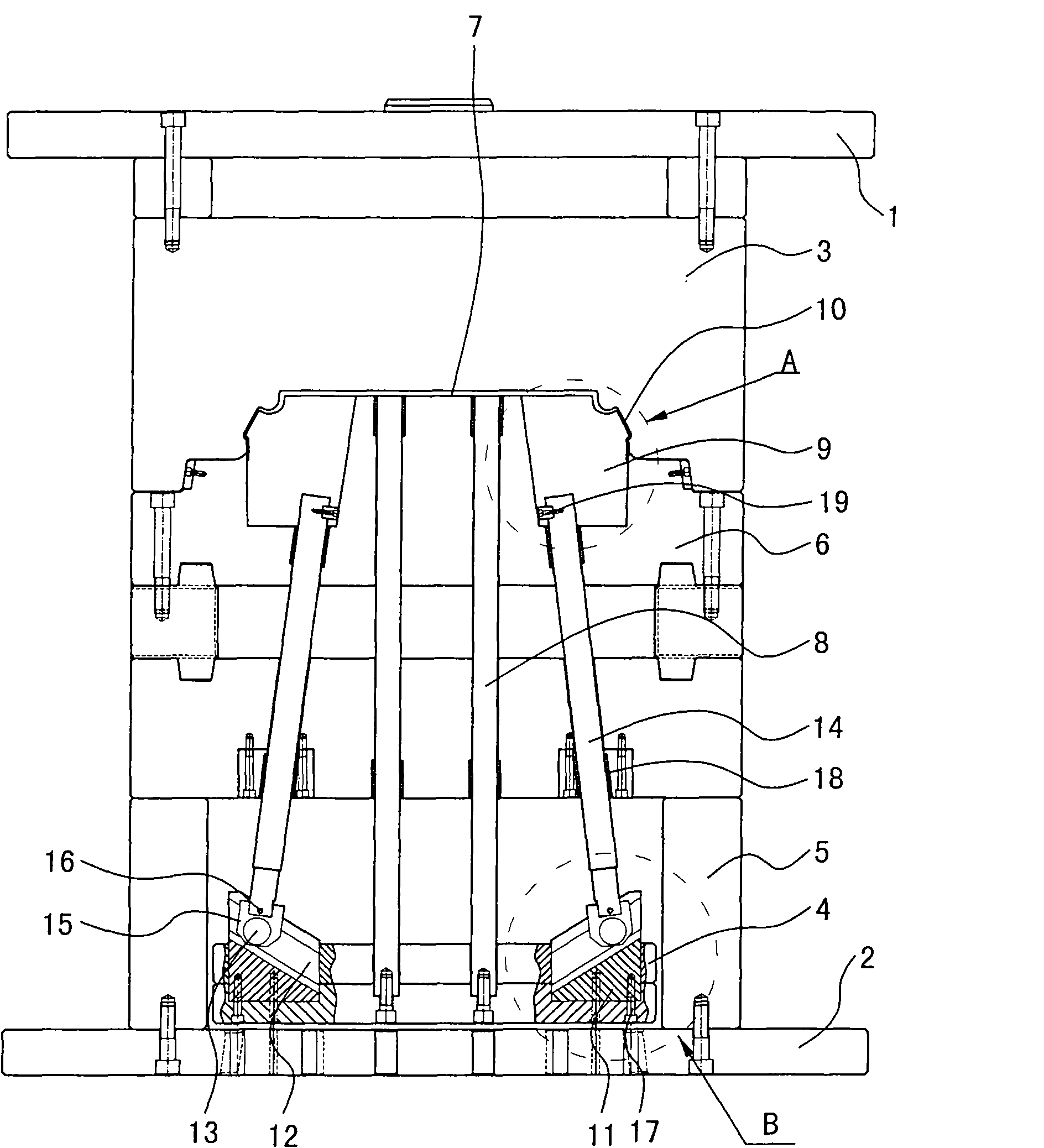

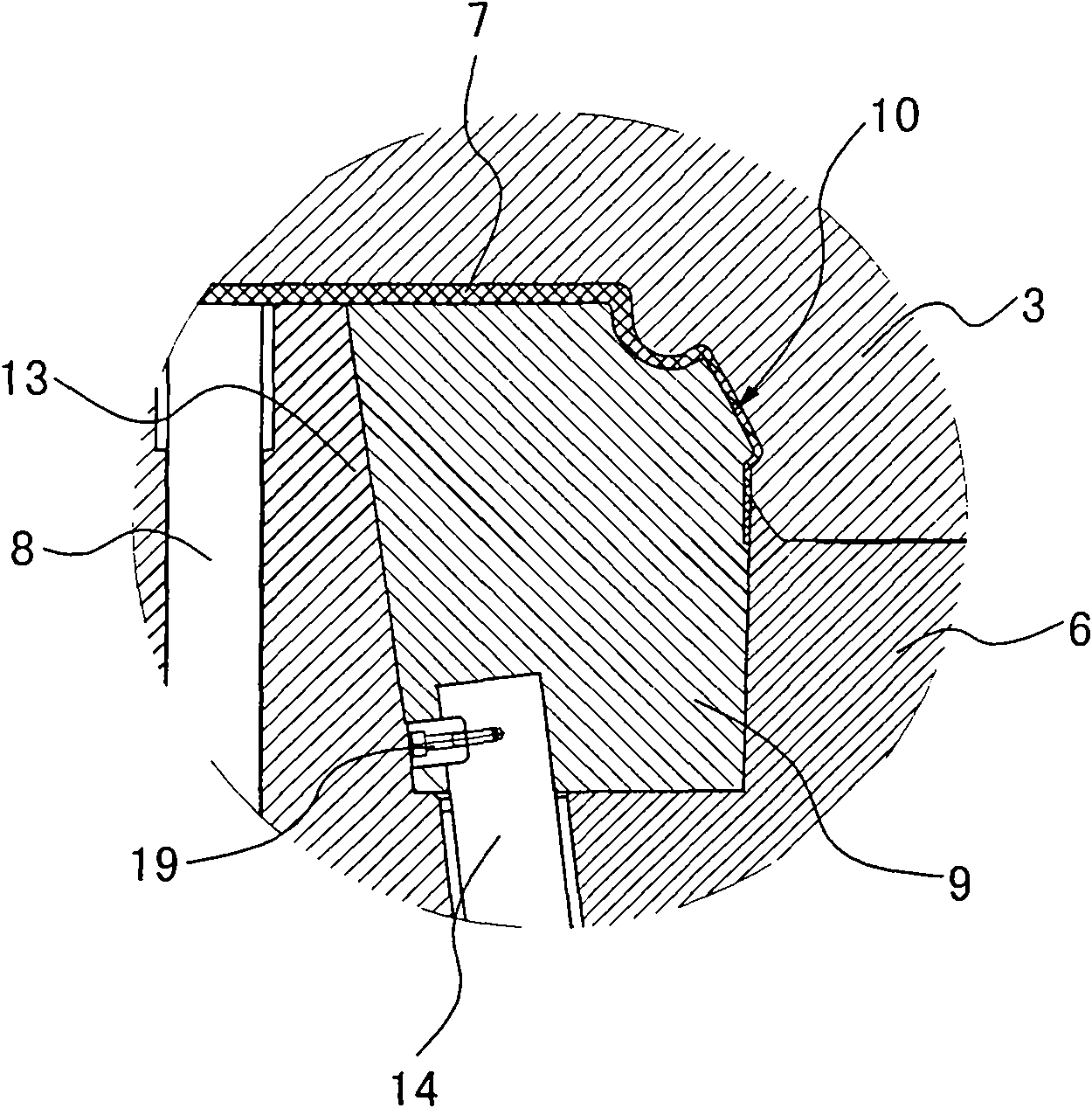

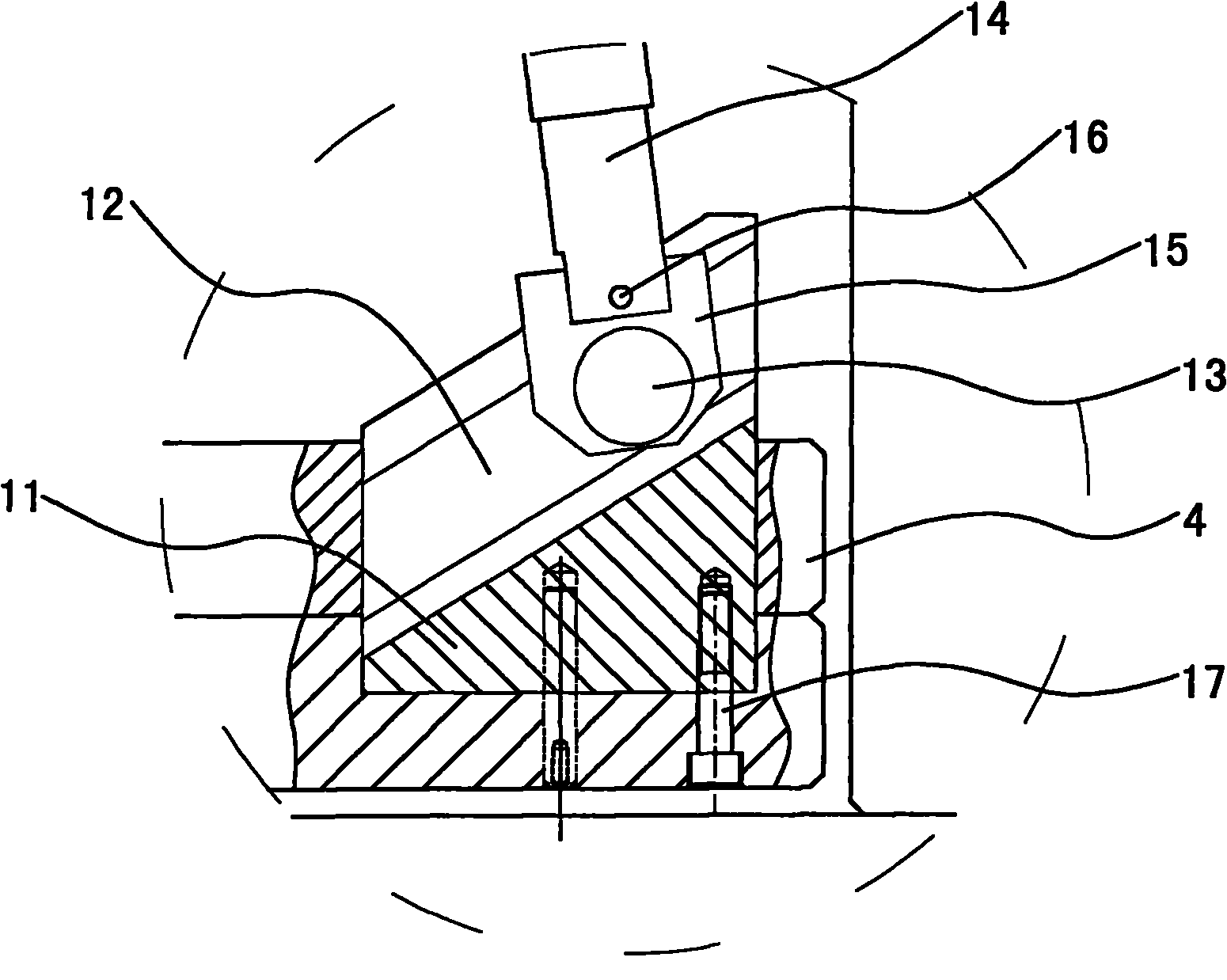

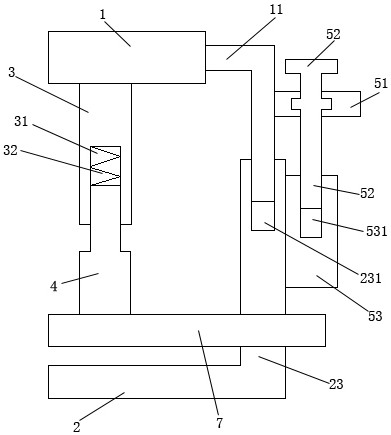

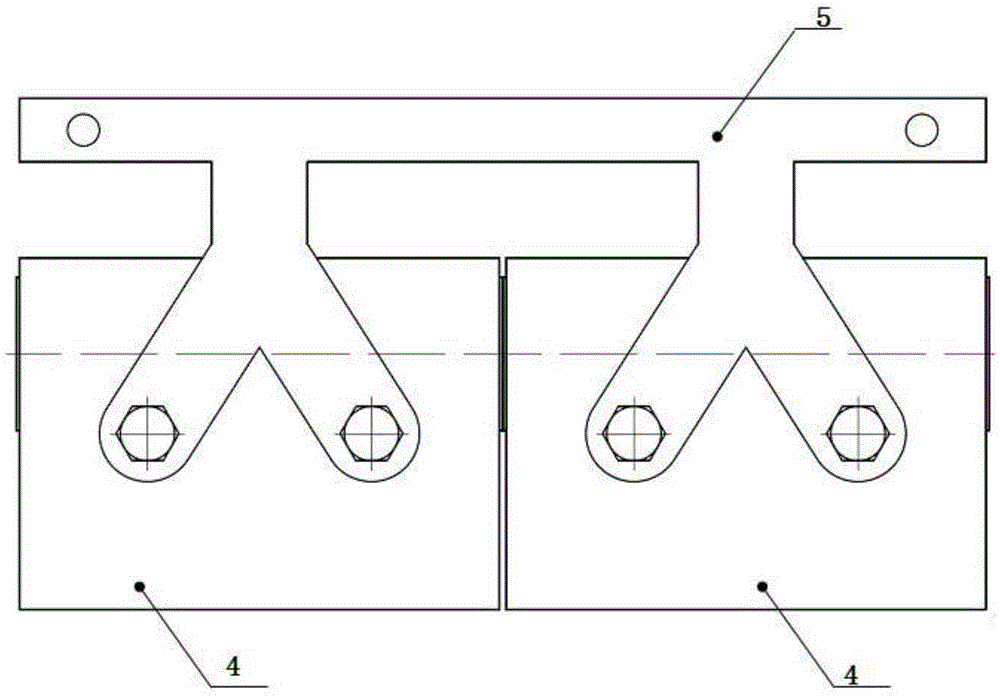

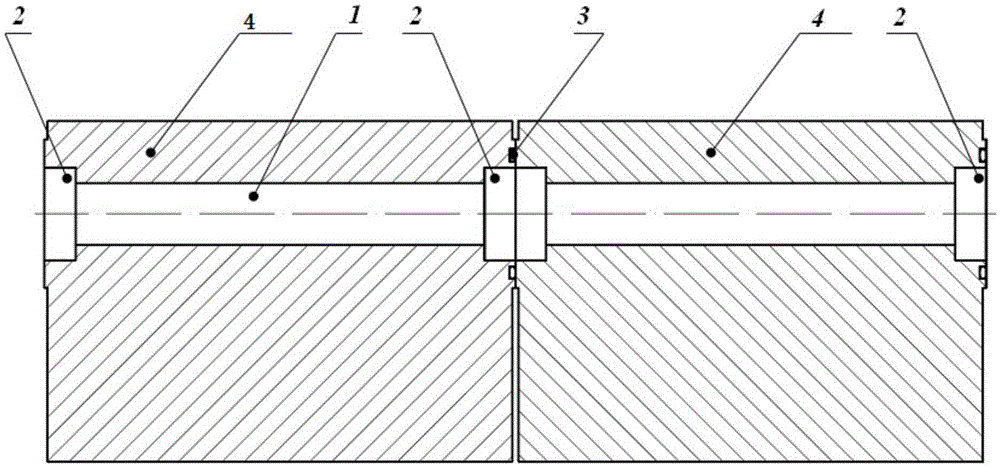

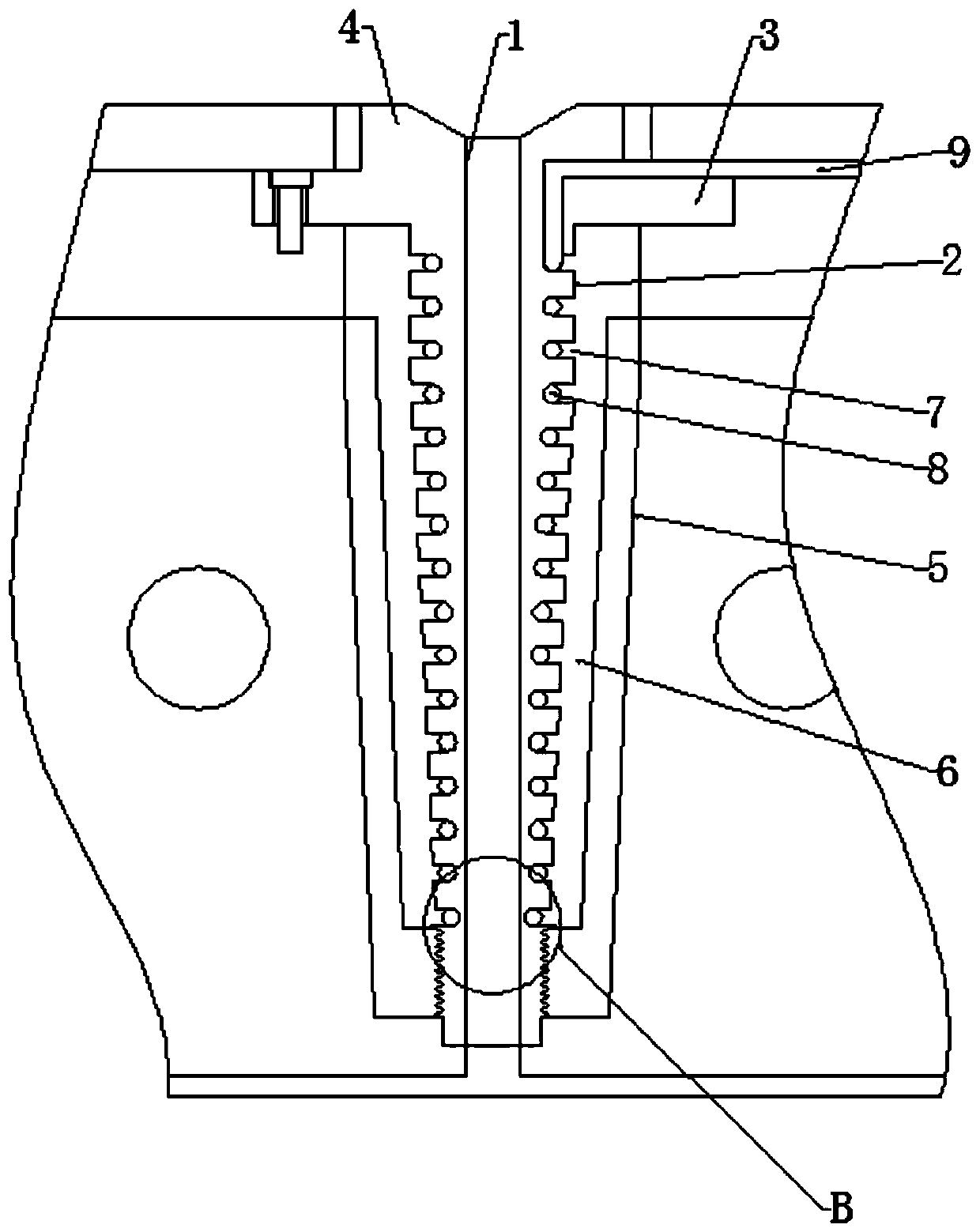

Internal core-pulling mechanism for inclined hole of injection-molded plastic piece

The invention provides an internal core-pulling mechanism for an inclined hole of an injection-molded plastic piece. The internal core-pulling mechanism comprises an upper mold plate and a lower mold plate; the upper template is connected with a cavity; a top plate and a mold foot are arranged on the lower mold plate; a mold core is arranged on the mold foot; the mold core and the cavity form a mold cavity; a molded plastic piece is arranged in the mold cavity; a straight top rod is arranged on the top plate; the straight top rod passes through the mold core to contact the plastic piece; an internal pulling block is arranged in the mold core; the internal pulling block is matched with the inclined hole of the plastic piece; the internal core-pulling mechanism is characterized in that: an inclined sliding seat is arranged on the top plate; an inclined chute is made in the inclined sliding seat; a rolling pin is arranged in the inclined chute; an inclined top rod is arranged on the rolling pin; and the inclined top rod passes through the mold core and is connected with the internal pulling block. According to the technical scheme, the internal core-pulling mechanism for the inclinedhole of the injection-molded plastic piece is ingenious in idea and simple in structure, reduces the production cost without additionally applying power, and has no interference in a water path hole of the mold and no influence on the cooling effect of the mold; moreover, the internal core-pulling mechanism can be used for processing all the injection-molded plastic pieces with the inclined holesor inclined blind holes, and has wide applicability and remarkably active effect.

Owner:ZHEJIANG KAIHUA MOLDS

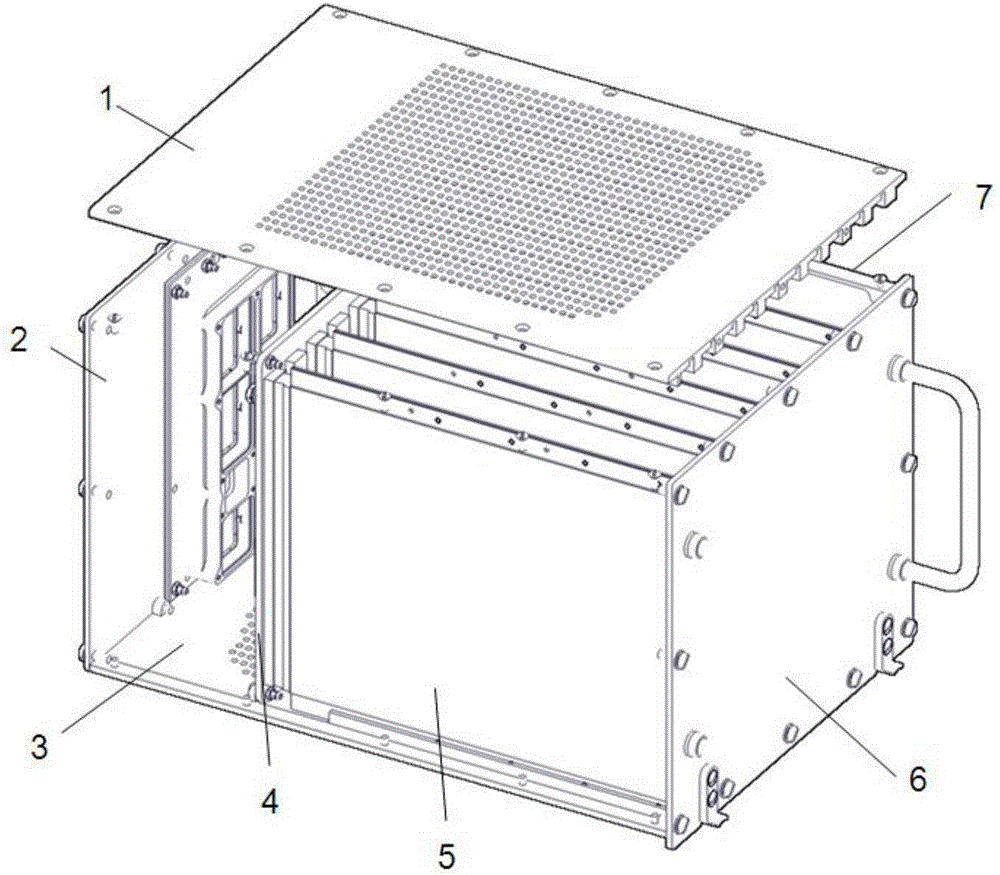

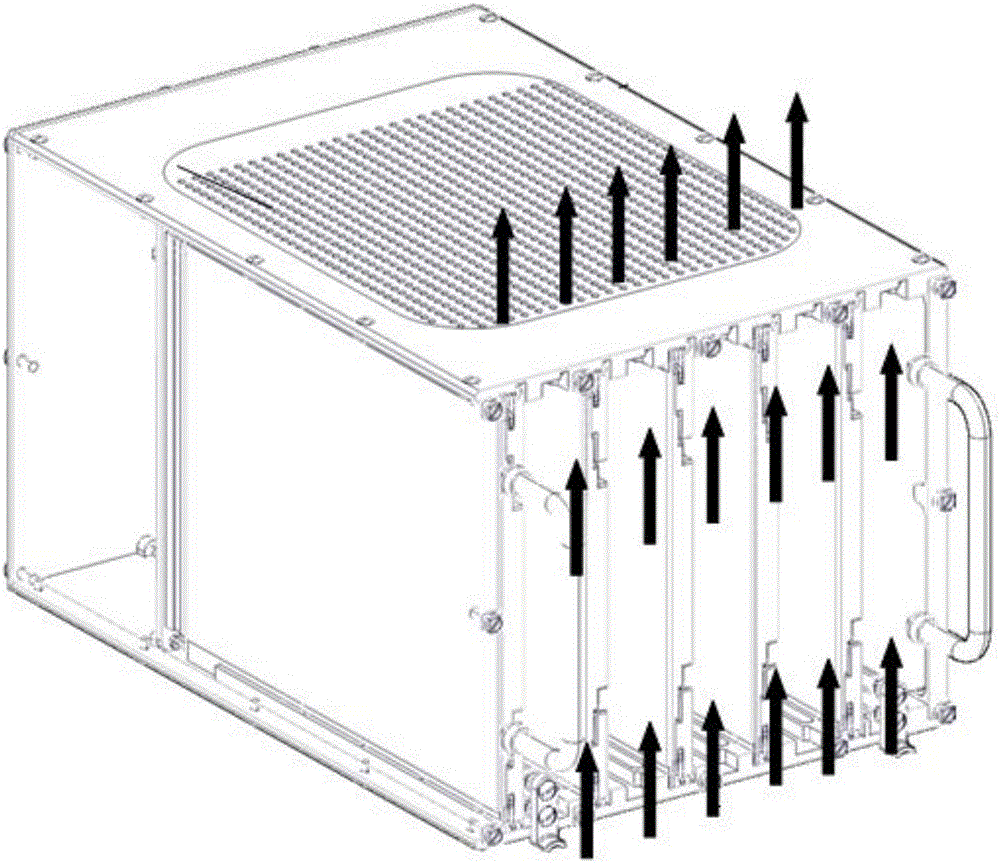

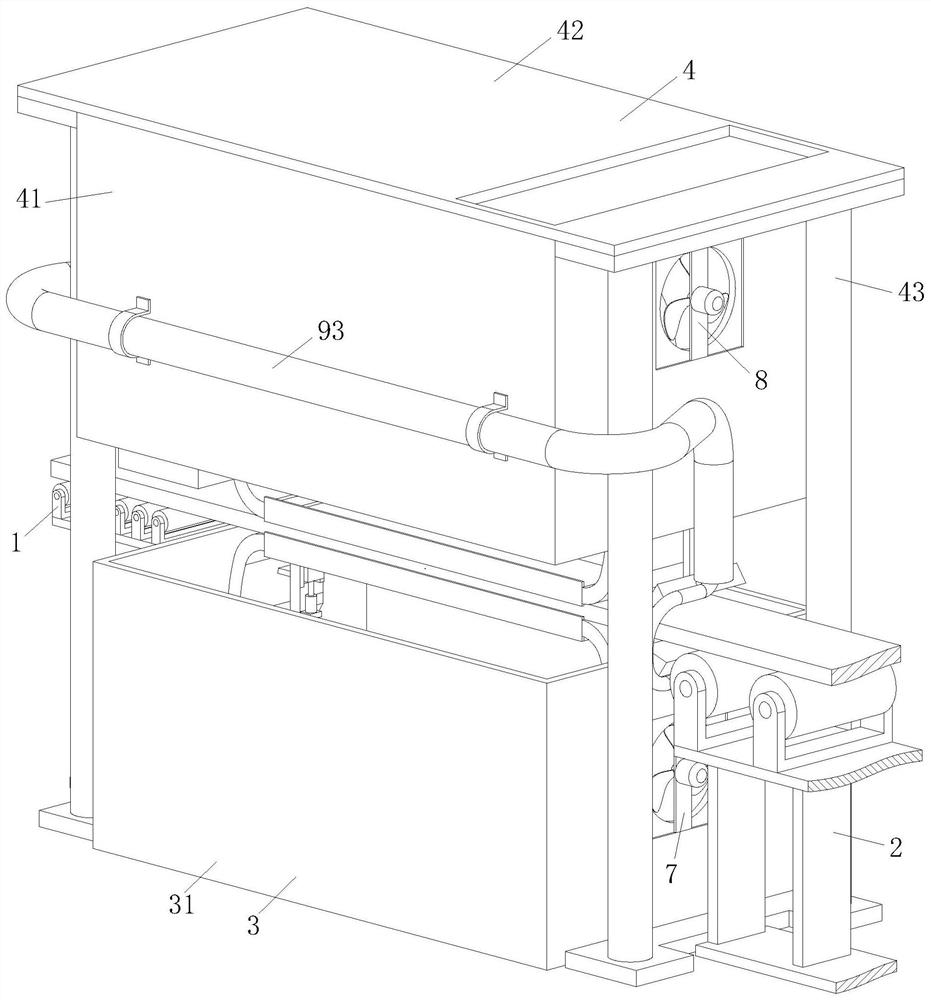

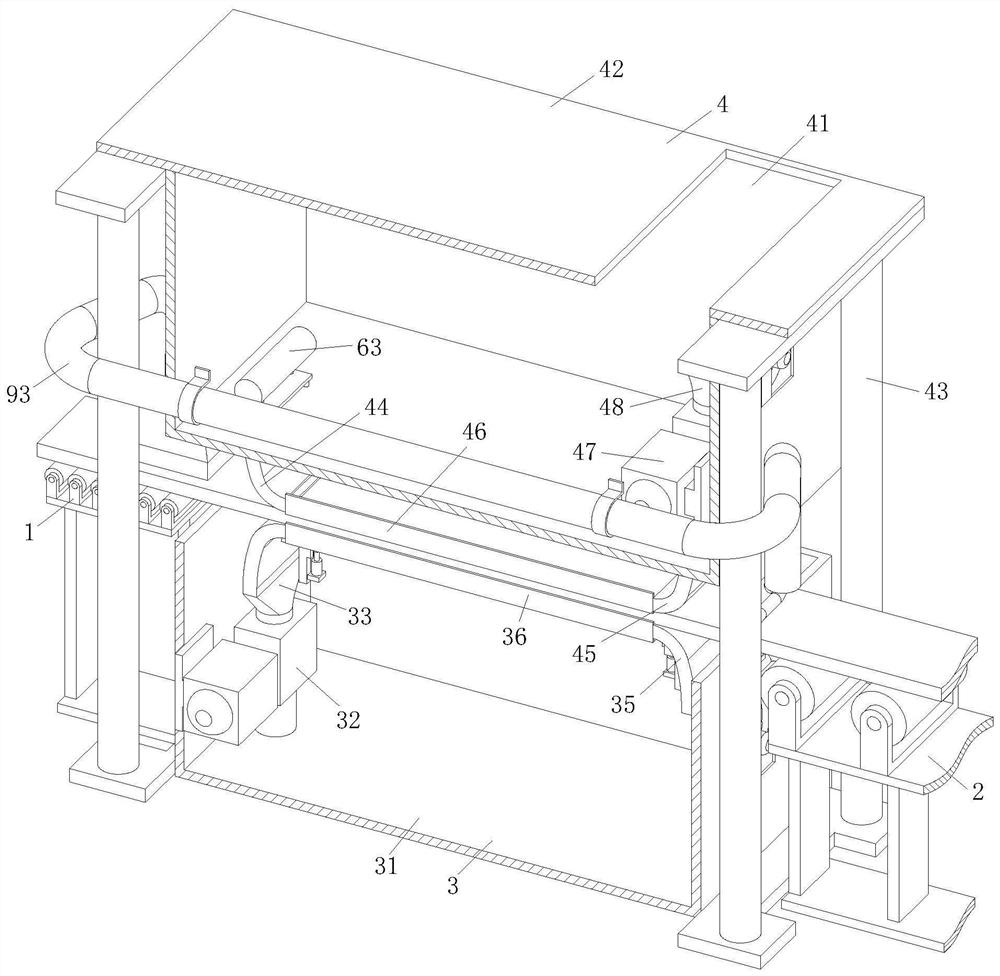

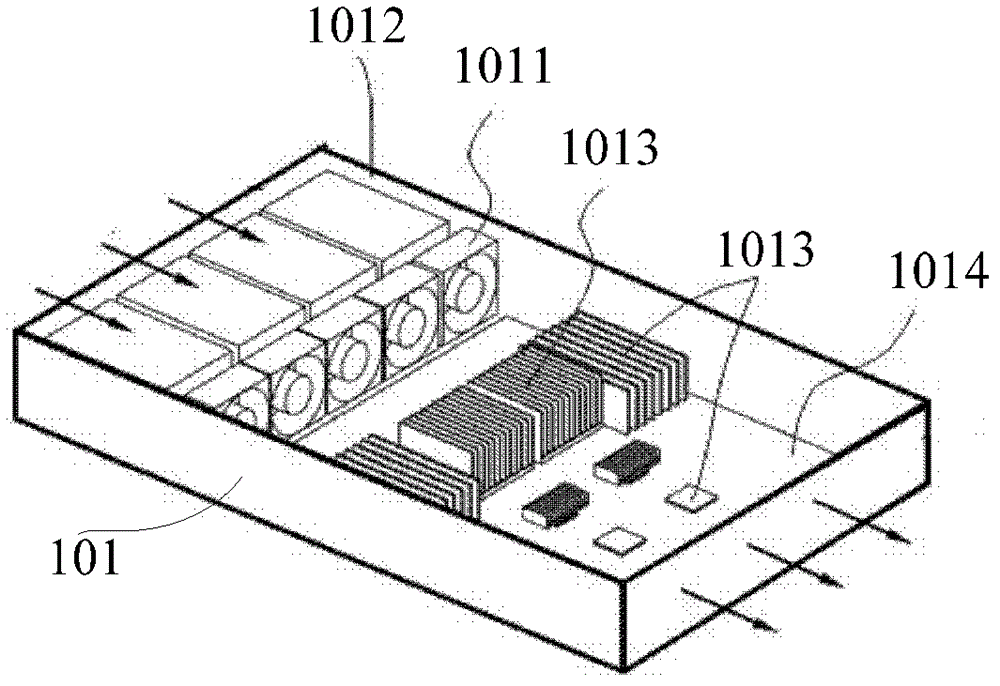

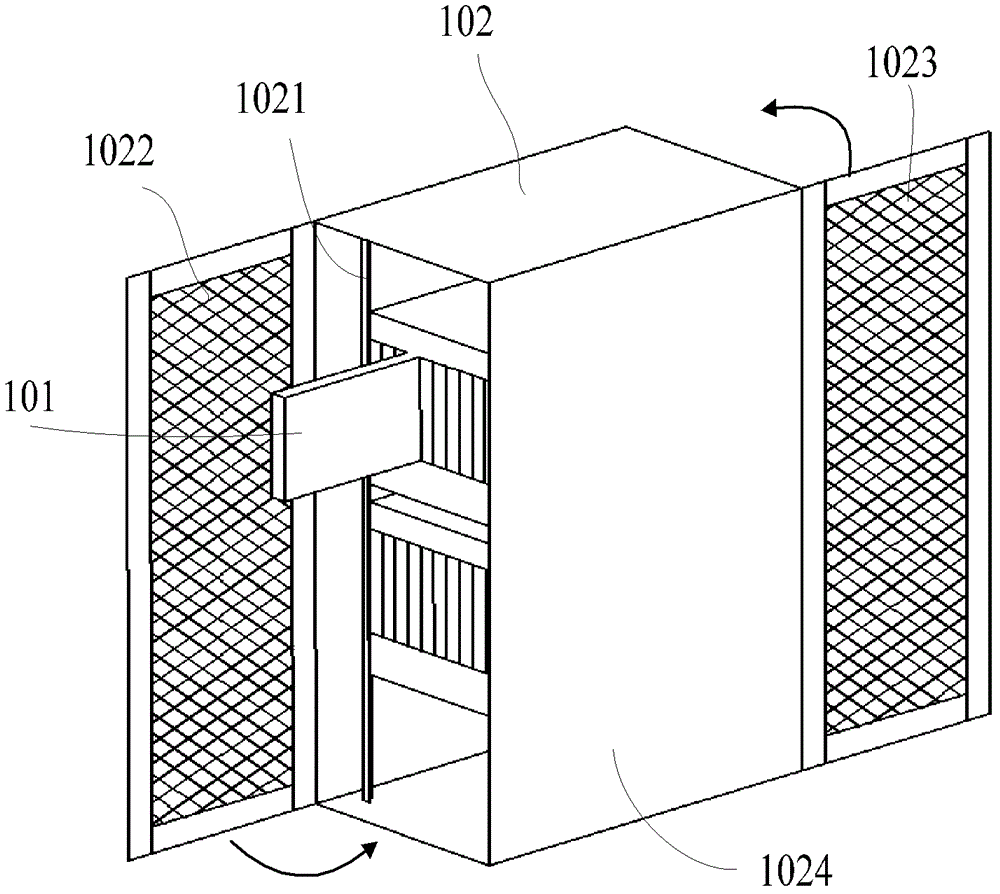

Electronic device cooling system with auxiliary cooling device

ActiveCN103037665ASolve the problem of not getting effective coolingSolve the problem of overheating caused by high temperatureCooling/ventilation/heating modificationsEngineeringElectronic equipment

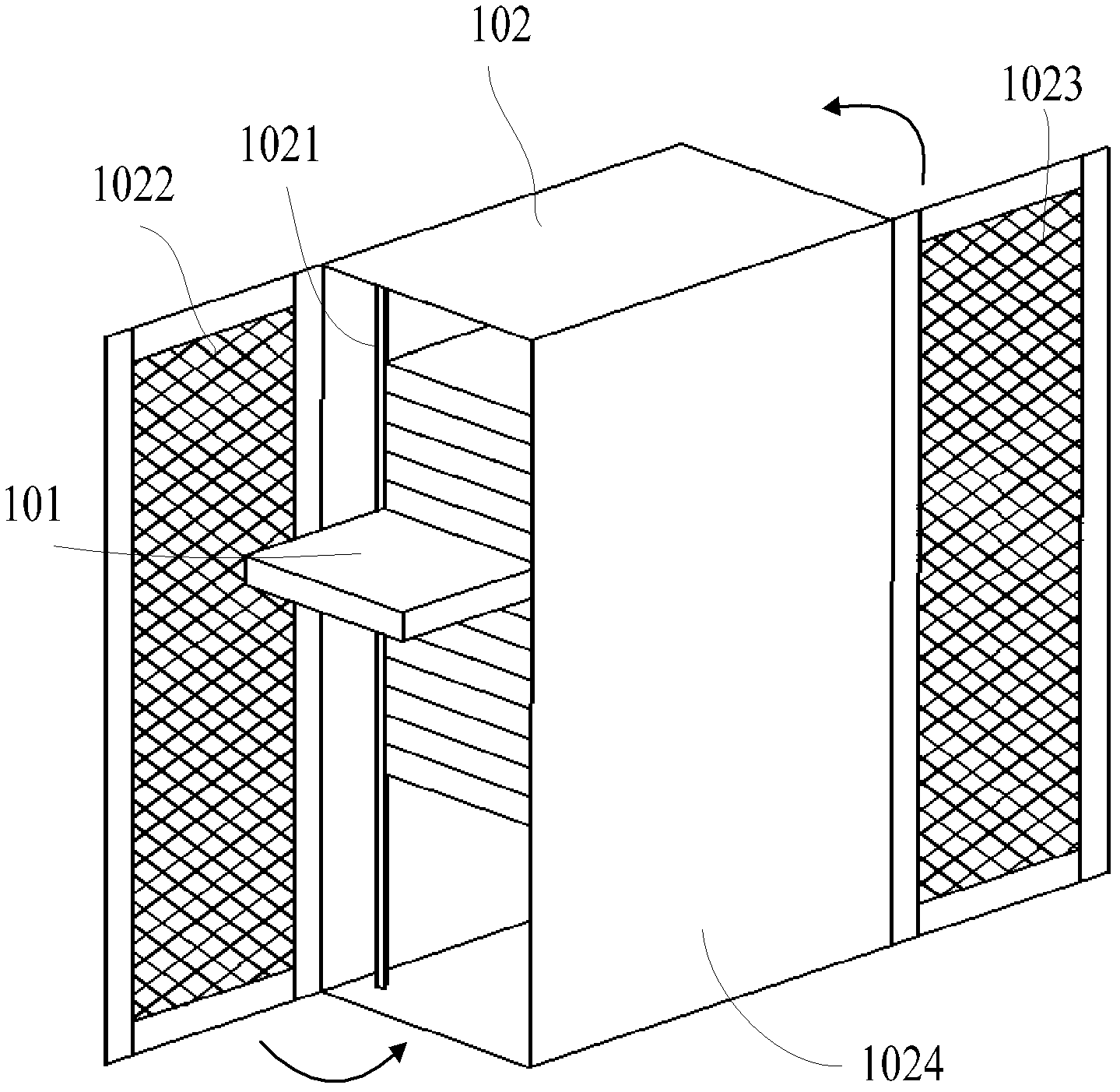

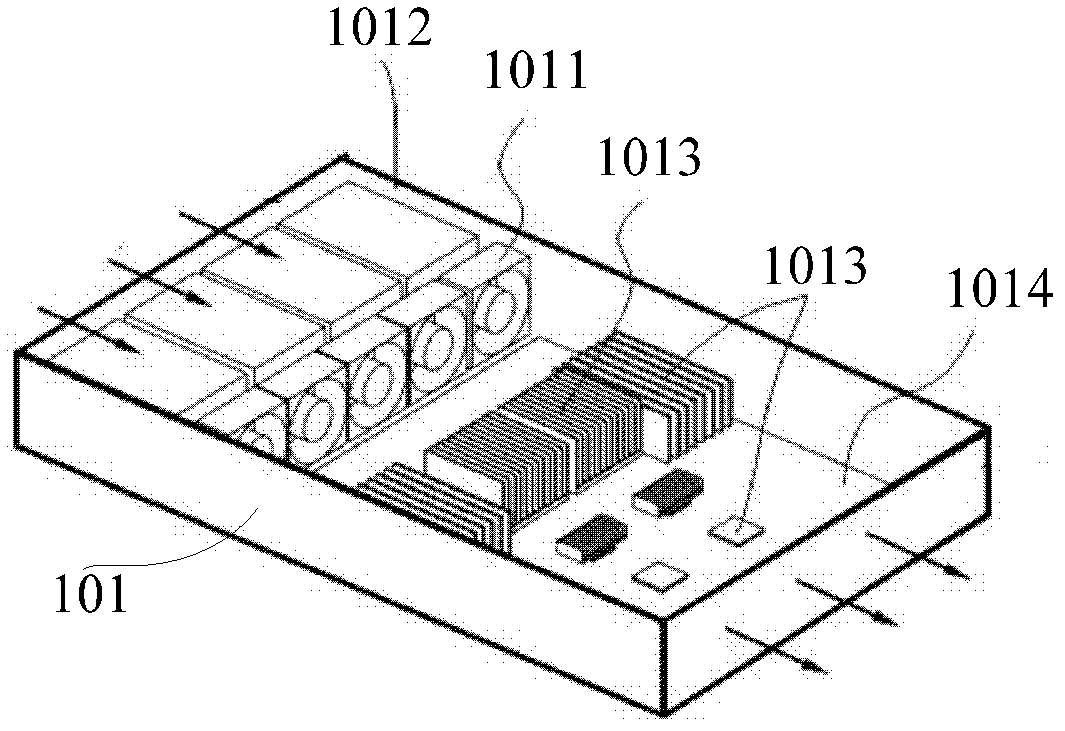

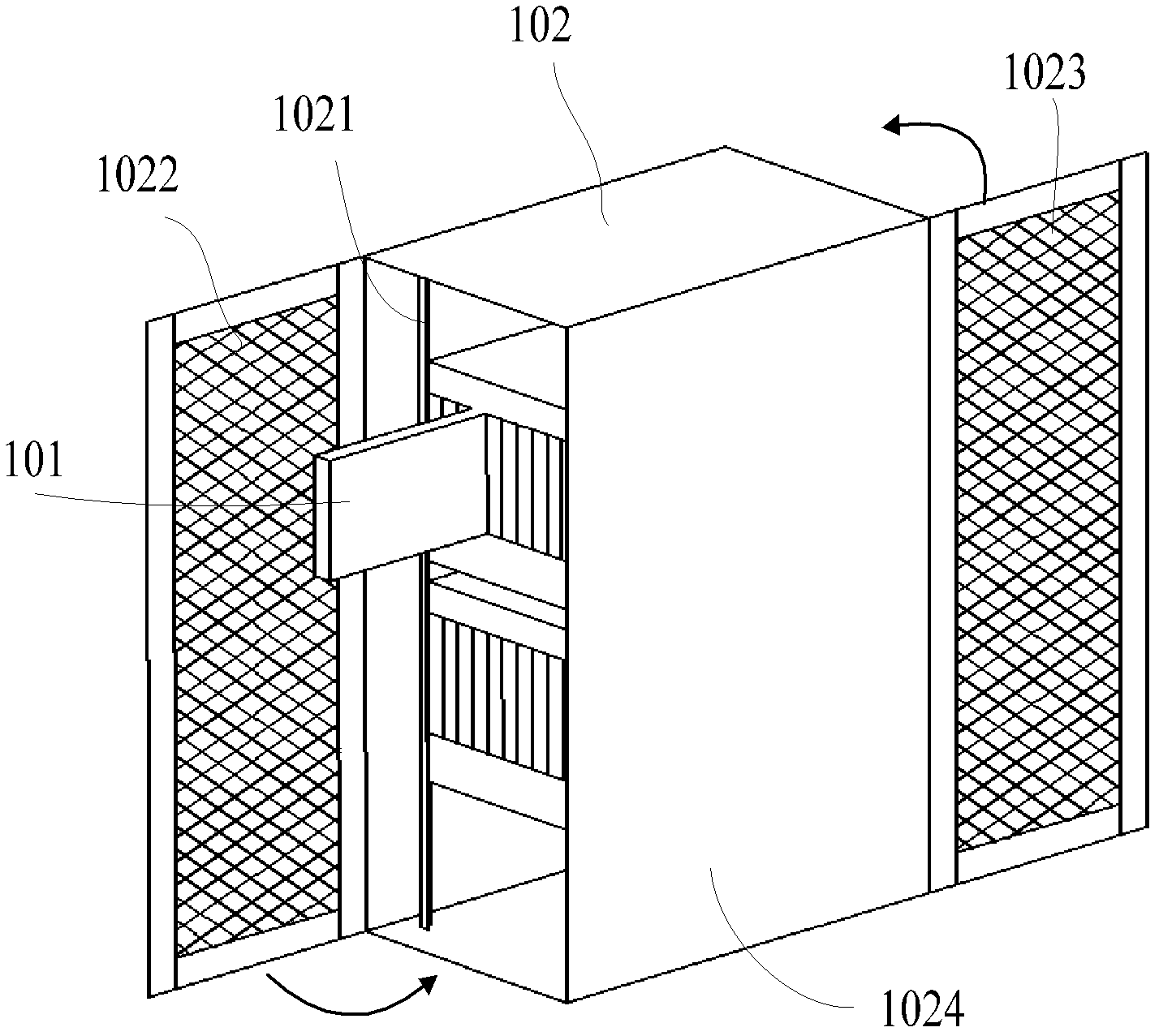

An embodiment of the invention discloses an electronic device cooling system with an auxiliary cooling device. The electronic device cooling system is used for cooling devices with high heating value in an electronic device machine case. The electronic device cooling system with the auxiliary cooling device comprises a machine cabinet, at least one electronic device machine case which is installed in the machine cabinet, and the auxiliary cooling device. The auxiliary cooling device comprises an air supercharging device, an air supply static pressure box and an air guide device. The air supply static pressure box is arranged on the inner side of the machine cabinet. The air supercharging device is arranged at the top or the bottom of the machine cabinet, and an air outlet on a lateral wall of the air supercharging device is communicated with a corresponding air inlet on a lateral wall of the air supply static pressure box. The air guide device is installed in the electronic device machine case, an air inlet of the air guide device is communicated with an air outlet of the air supply static pressure box, and an air outlet of the air guide device is aligned at the devices in the electronic device machine case.

Owner:深圳市新凯来技术有限公司

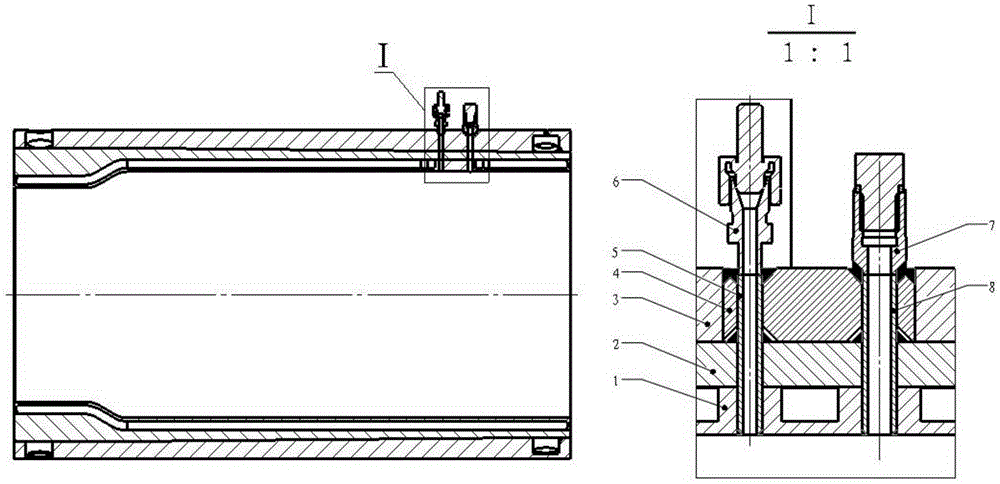

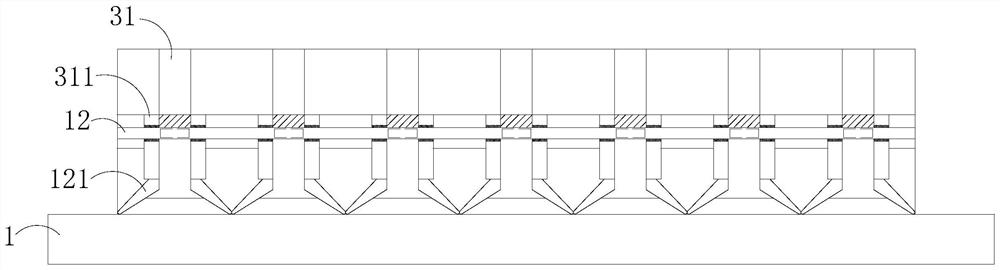

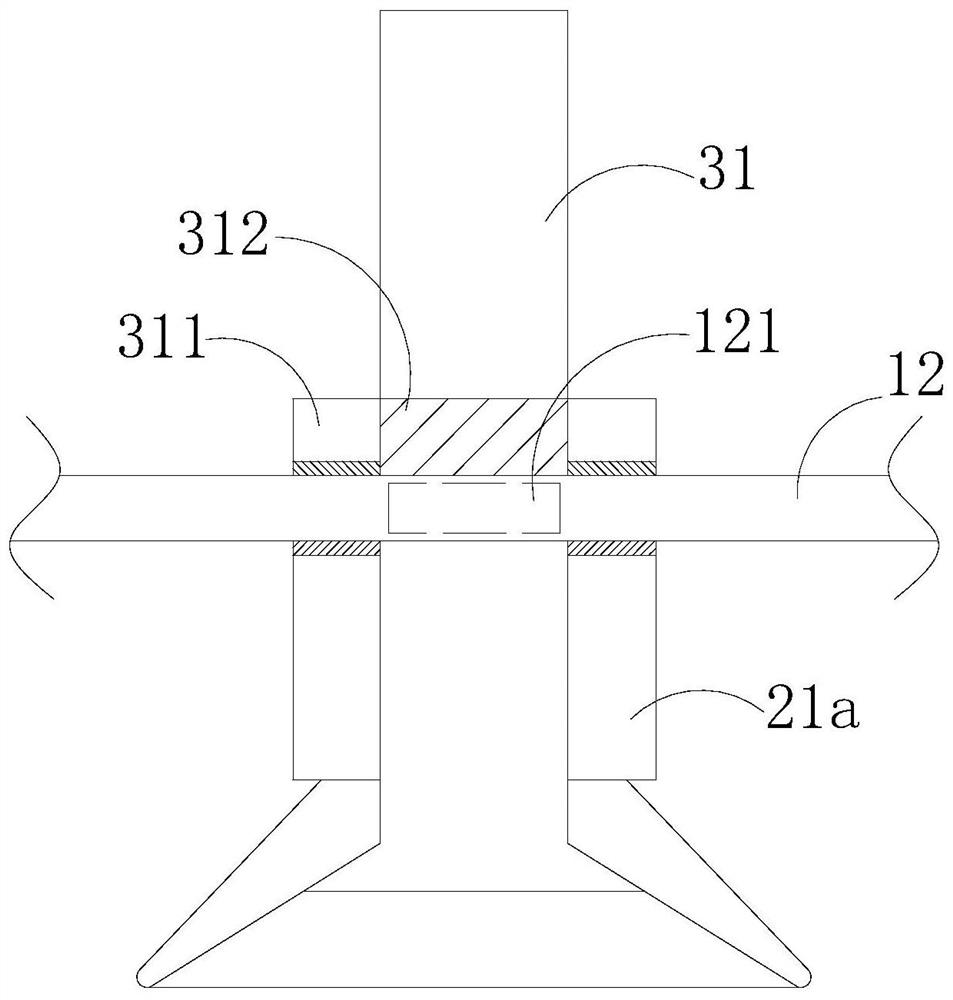

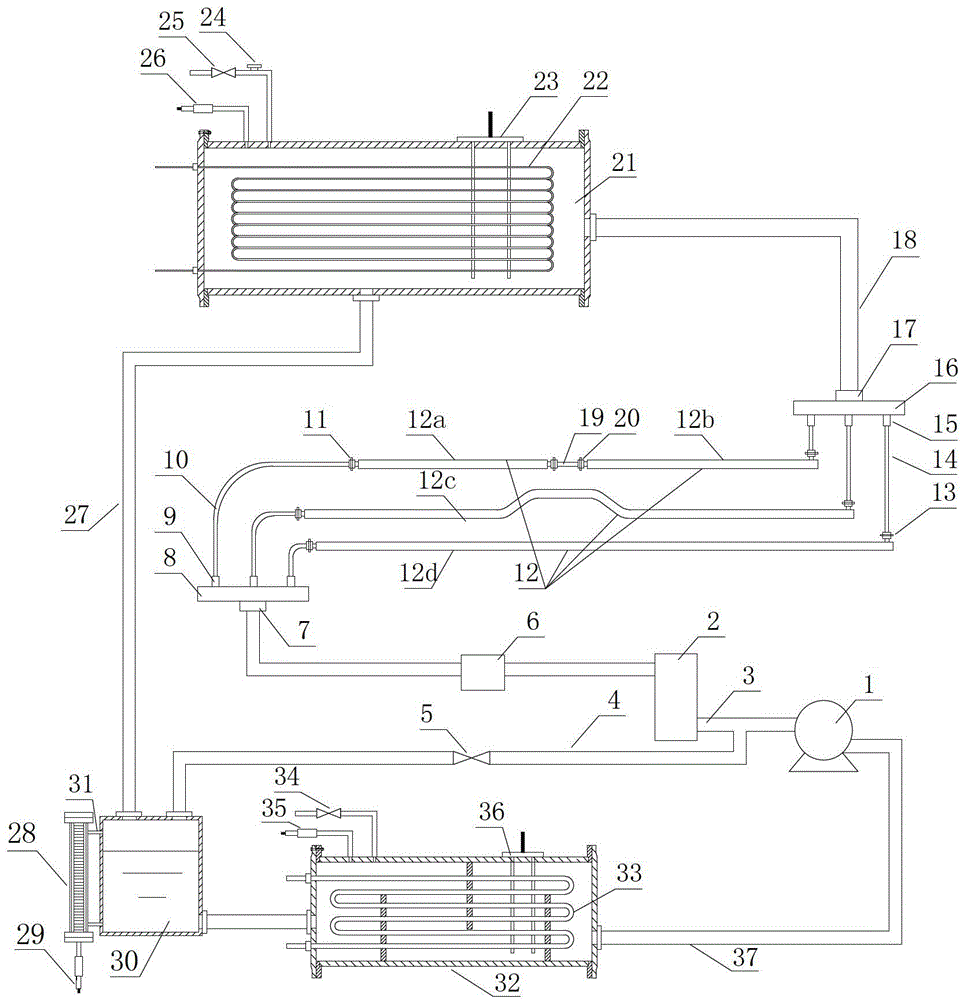

Forced circulation evaporation cooling device of hydro-generator stator busbar

ActiveCN102969838AAvoid short circuit accidentsImprove securityCooling/ventillation arrangementBusbarEvaporation

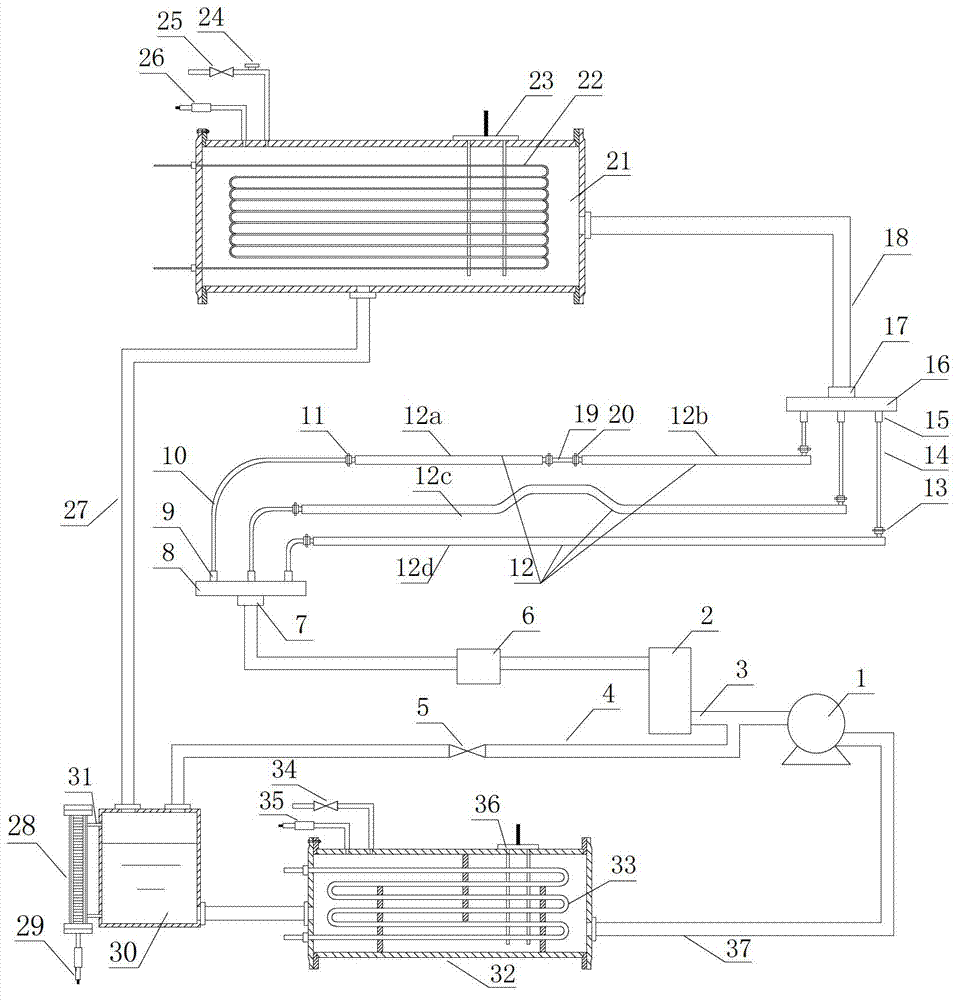

Provided is a forced circulation evaporation cooling device of a hydro-generator stator busbar. The stator busbar (12), a condenser (21), a liquid storage tank (30), a cooling device (32), a pump (1), a pressure stabilizing tank (2), a flowmeter (6), a liquid dividing pipe (8), a gas collecting pipe (16), a liquid supply main pipe (3), a gas outlet pipe (18), a liquid return main pipe (27), a total liquid return main pipe (37), a by-pass pipe (4) and an electro-liquid separation joint are connected to form an evaporative cooling circulation loop. An evaporative cooling medium in the loop is driven by a pump. The stator busbar includes one or a plurality of busbar branches, an inlet and an outlet of each busbar branch are respectively connected with the liquid dividing pipe and the gas collecting pipe through the electro-liquid separation joint and an insulation guide pipe, the busbar branches are connected in parallel, and the stator busbar is connected with the pump, the condenser, the cooling device and the like to form the independent evaporative cooling circulation loop. The forced circulation evaporation cooling device enables a plurality of busbars to be combined to form a unified parallel-connection pipeline and builds the independent evaporative cooling circulation loop.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

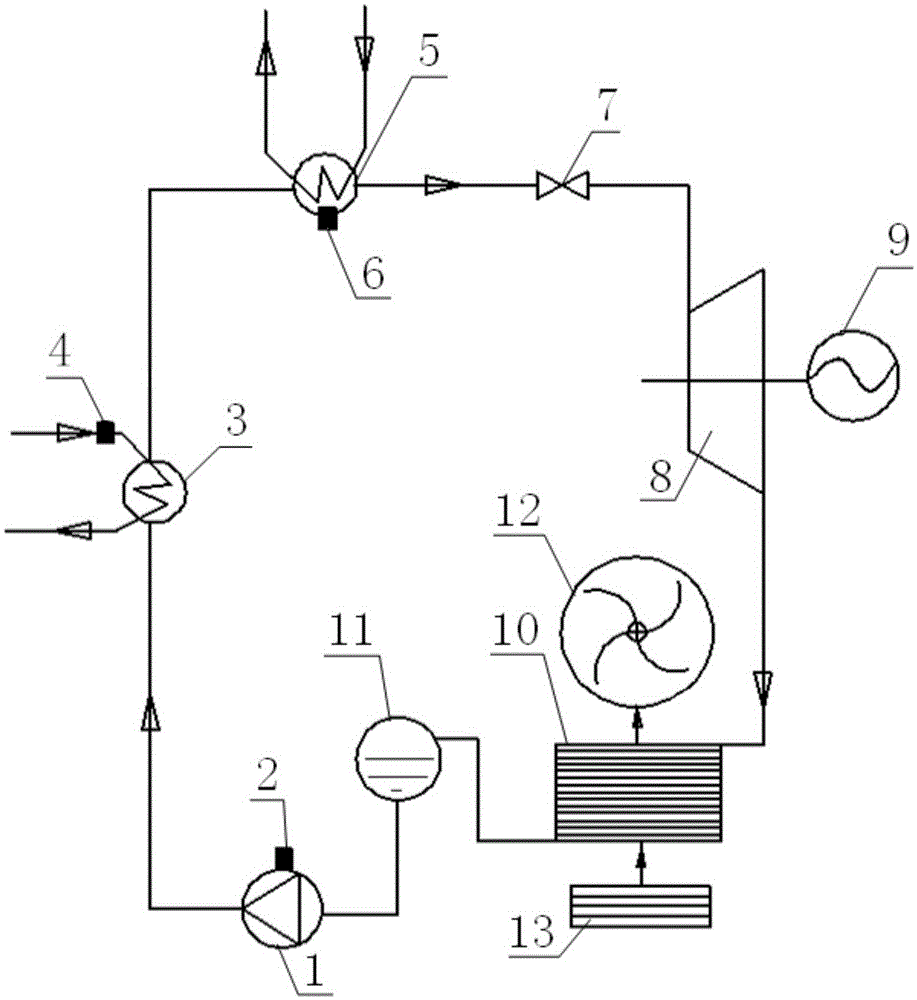

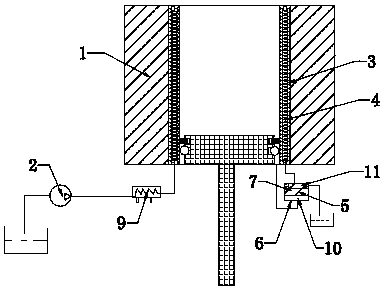

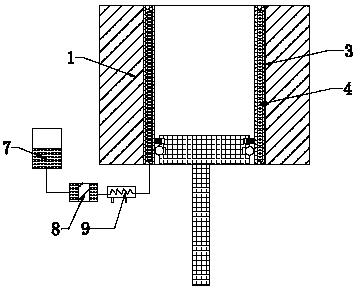

Energy recovery system and method for automobile engine

ActiveCN105317584ADoes not affect cooling effectAffect cooling effectInternal combustion piston enginesEngine componentsFuel oilLiquid storage tank

The invention discloses an energy recovery system and method for an automobile engine. The energy recovery system for the automobile engine comprises an electric-control pump, a steam turbine, a condenser, a liquid storage tank, a controller, a pressure-limiting valve, an energy recovery mechanism, a first heat exchanger, a coolant temperature sensor, a second heat exchanger and a working medium temperature sensor. The coolant temperature sensor, the working medium temperature sensor and the electric-control pump are electrically connected with the controller. The energy recovery mechanism is installed on an output shaft of the steam turbine. The liquid storage tank, the electric-control pump, the first heat exchanger, the second heat exchanger, the pressure-limiting valve, the steam turbine and the condenser form a circuiting flow channel for working media. In the flowing process of the working media, heat of the engine is absorbed through the first heat exchanger and the second heat exchanger, and the energy recovery mechanism is driven by the steam turbine to recover energy. According to the energy recovery system and method, redundant heat of a cooling system and an exhausting system can be fully recovered, the energy utilization rate of fuel oil is increased, and meanwhile normal cod starting of the engine is prevented from being affected.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

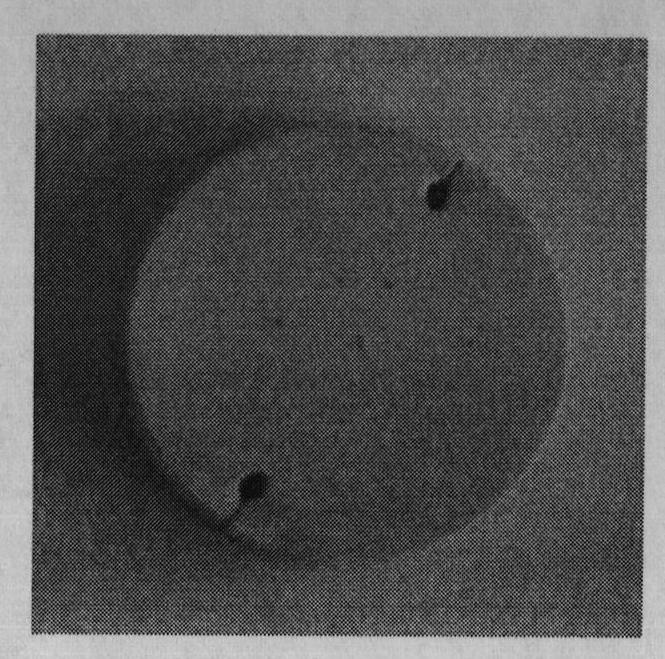

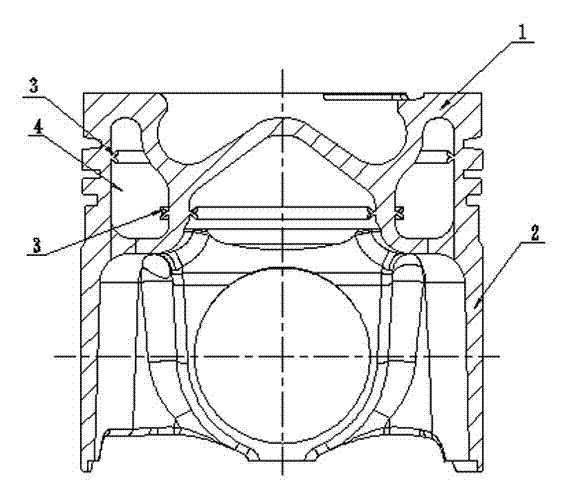

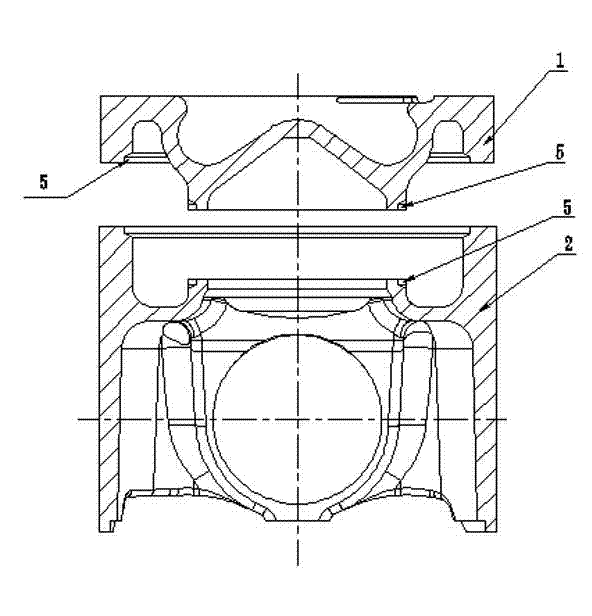

Machining method of friction welding of forged steel piston

InactiveCN103174537AHigh dimensional accuracyReduce weightMachines/enginesPistonsFriction weldingCooling effect

The invention provides a machining method of friction welding of a forged steel piston. The concrete steps are as follows: (1) dividing the steel piston into a piston head and a piston skirt which are respectively machined to be semi-finished products, wherein the shape of an inner cooling oil channel, an oil inlet and an oil outlet of the piston head and the piston skirt are machined to be in the sizes of a finished product, clearance of 1.5-4mm is reserved in the height direction, and a gap is reserved in the position, on one side of the inner-cooling oil channel, on the welding surface of the piston head and the piston skirt; and (2) combining the piston head and the piston skirt into a whole through the friction welding, wherein the gap is right filled with the turnup edge of a friction welding seam, and then carrying out other machining on the piston. The turnup edge is prevented from occurring on the inner side of the cooling oil channel, cooling effect of cooling oil on the top of the piston can not be affected, no turnup edges exist in the inner cooling oil channel, the weight of the piston can be reduced, the load of a connecting rod mechanism can be lightened, due to the fact that the turnup edge is embedded, the phenomenon that the inner turnup edge is scoured by the cooling oil to fall off to form hard particles, and risks including engine scraping and the like are caused is avoided.

Owner:DONGFENG PISTON & BEARING

Method for confirming damage of cooling water pipe of blast furnace cooling wall

InactiveCN102840953AQuick searchQuick and efficient searchMeasurement of fluid loss/gain rateCooling effectAir pump

The invention relates to a method for confirming damage of a cooling water pipe of a blast furnace cooling wall. The method comprises the following steps of: 1) preparing a wind belt before damping down a blast furnace, one end of the wind belt is connected with a blast furnace compressed air pump, the other end of the wind belt is connected with a three-way joint through a valve, a pressure meter is arranged at one side of the three-way joint and a connector is arranged at the other side of the three-way joint; 2) leading out each section of cooling water pipe which needs to be molded after damping down the blast furnace and when the furnace body has no coal gas; 3) utilizing water draining valves of the cooling water pipe to connect the wind belt onto the water draining valves of the cooling water pipe, and molding section by section according to the molding requirements; 4) confirming the damaged cooling water pipe after the molding, changing the pipe to communicate with industrial clean circulation water. Compared with the prior art, the method disclosed by the invention has the beneficial effects that the method has the characteristics of low cost, simple structure, reasonable design, convenience in use, high accuracy and high practicability; and moreover, cooling effects of other cooling walls are not affected, at the same time, the damaged cooling wall can be checked rapidly and effectively, and corresponding measures can be taken in time, so as to improve working efficiency.

Owner:ANGANG STEEL CO LTD

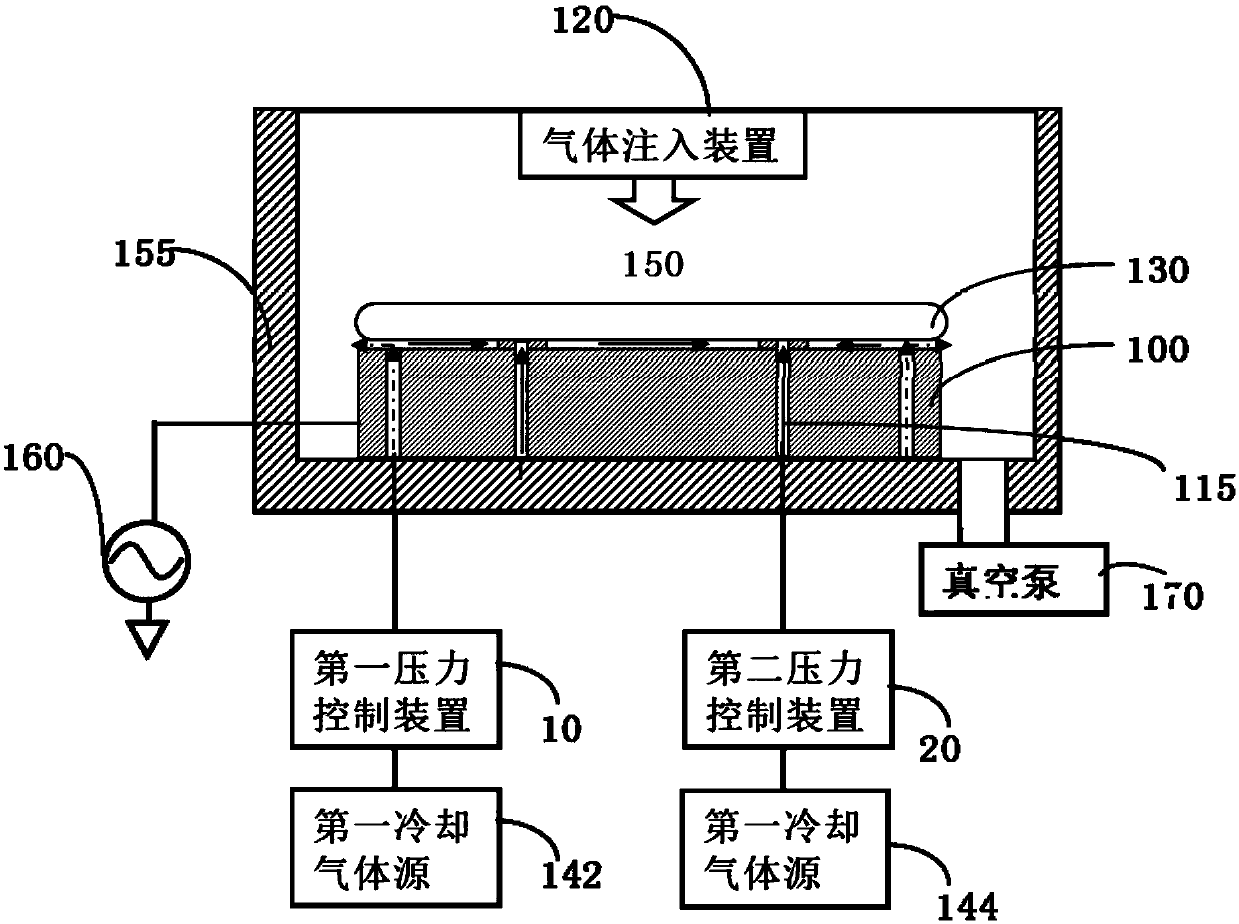

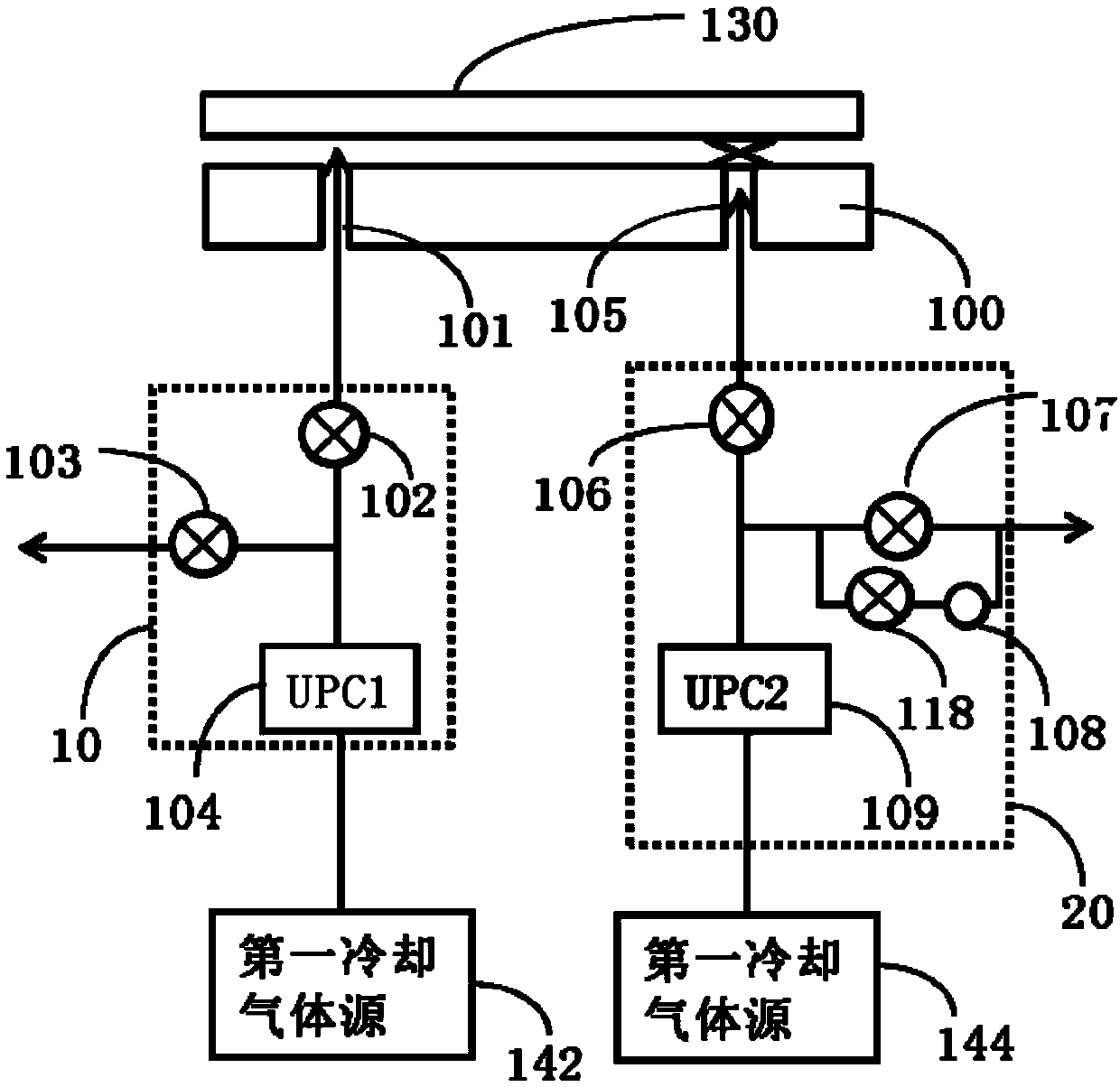

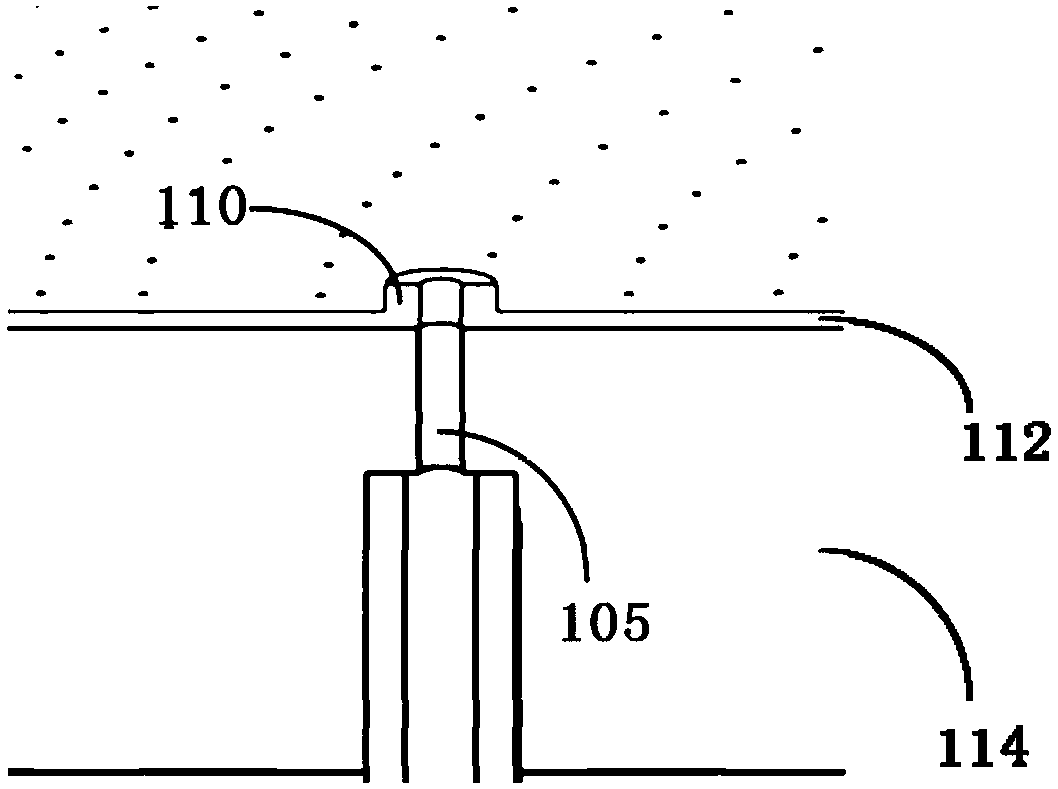

Lifting thimble assembly, electrostatic chuck and processing device with electrostatic chuck

ActiveCN110896045ASufficient supplyAvoid enteringElectric discharge tubesSemiconductor/solid-state device manufacturingPressure controlPhysics

The invention discloses a lifting ejector pin assembly, an electrostatic chuck provided with the lifting ejector pin assembly and a processing device where the electrostatic chuck is located. The lifting ejector pin assembly comprises a lifting ejector pin. The channel is used for accommodating the lifting thimble; the channel for accommodating the lifting thimble is connected with a pressure control device; a sealing ring is arranged at one end, close to the substrate, of the channel for accommodating the lifting thimble; the upper surface of the sealing ring is in contact with the back surface of the substrate in the technological process, so that gas on the back surface of the substrate is prevented from entering the channel for accommodating the lifting ejector pin, and the pressure control device can independently control the pressure in the channel for accommodating the lifting ejector pin.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

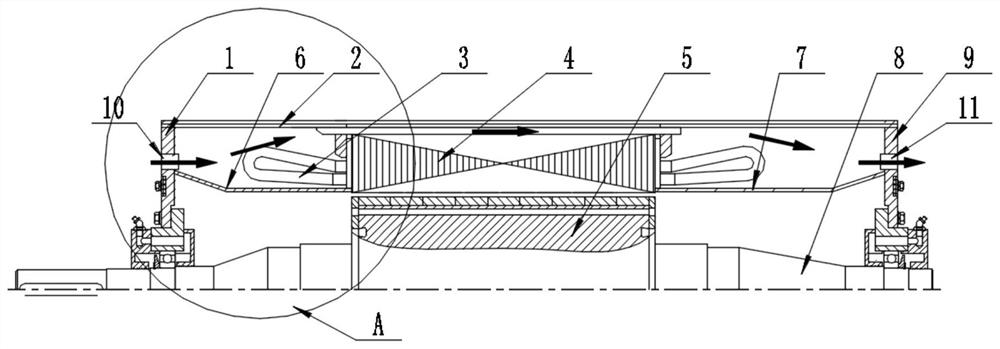

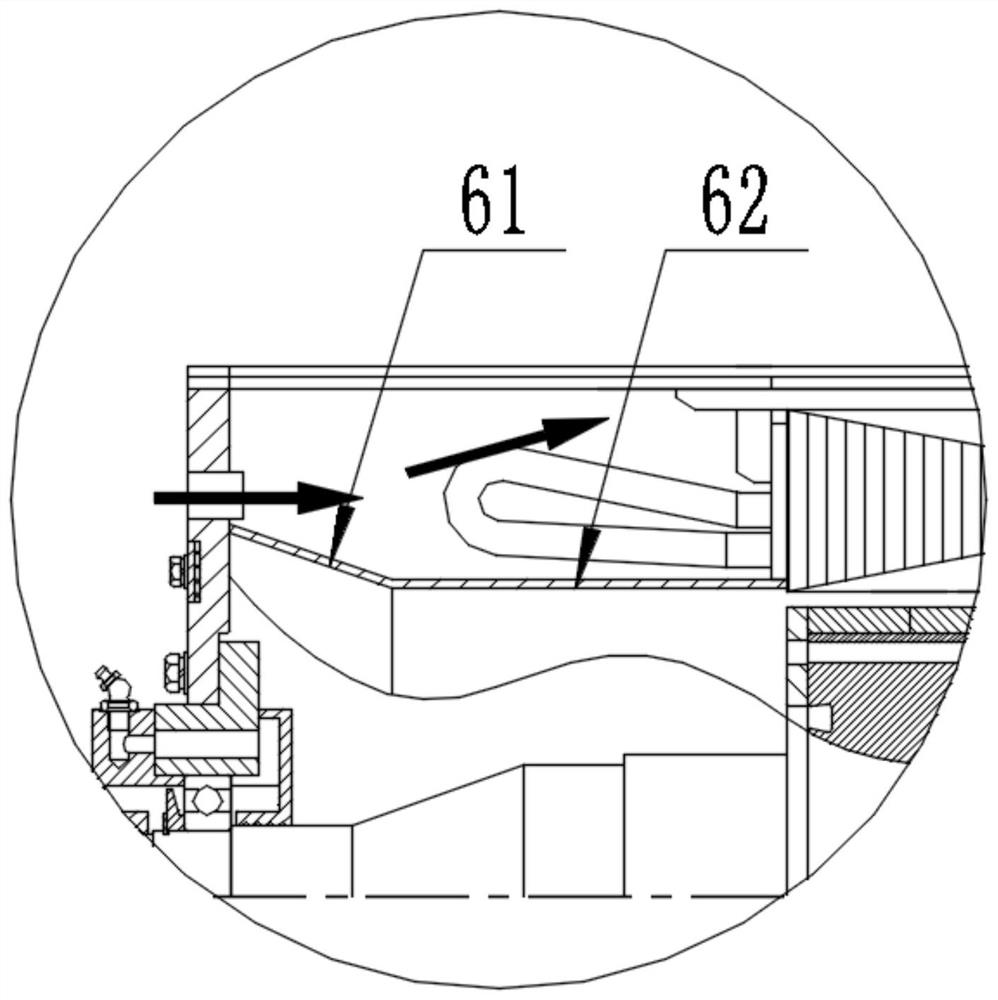

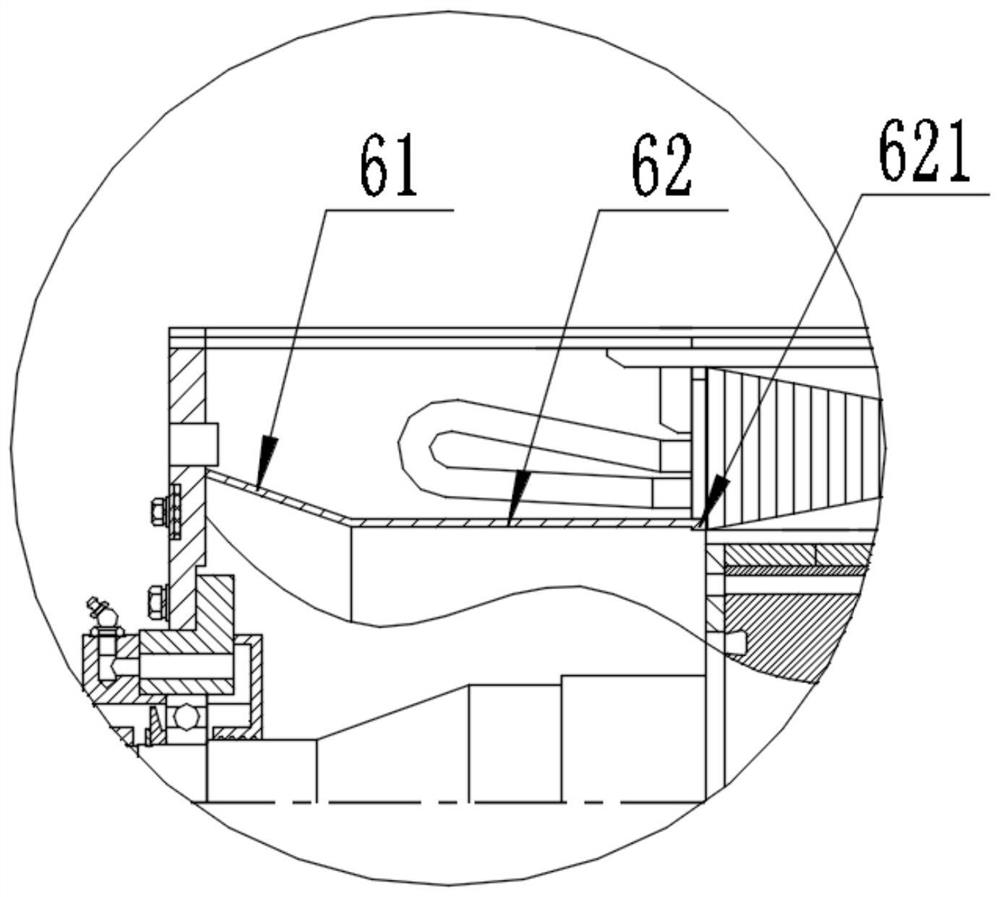

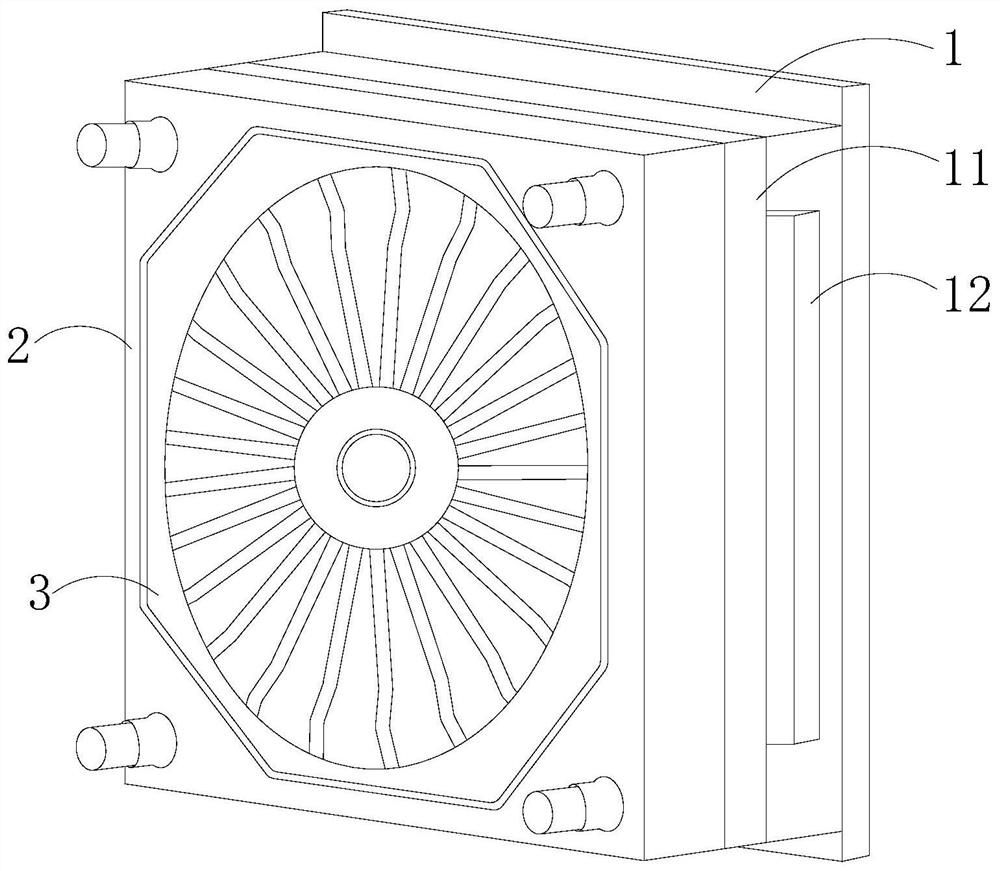

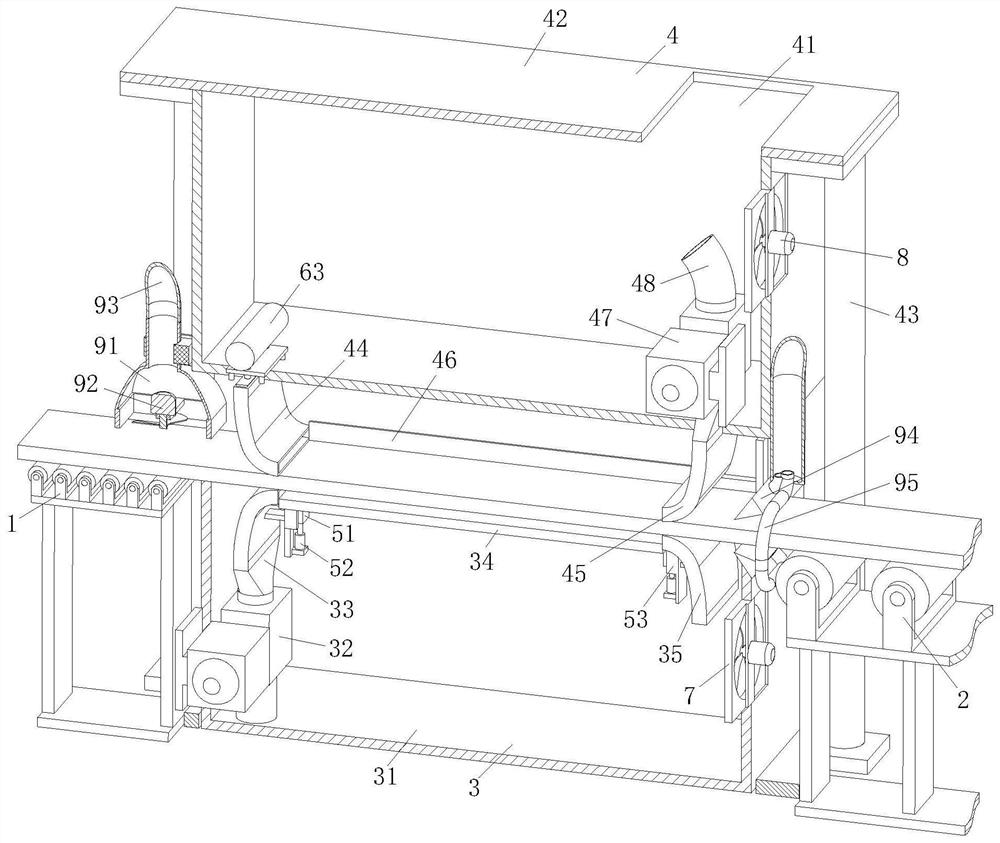

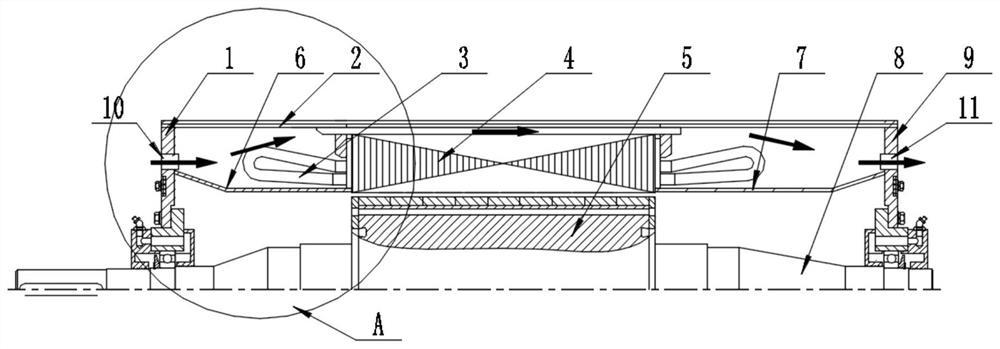

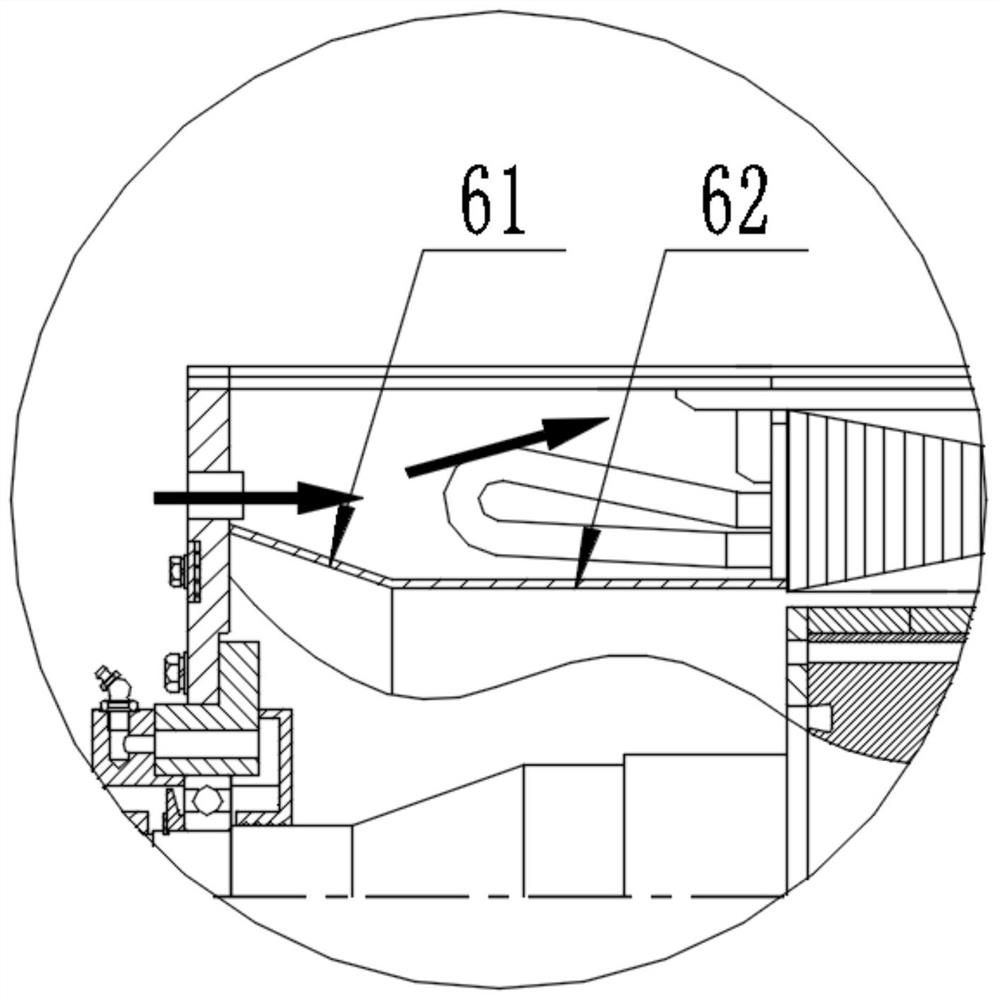

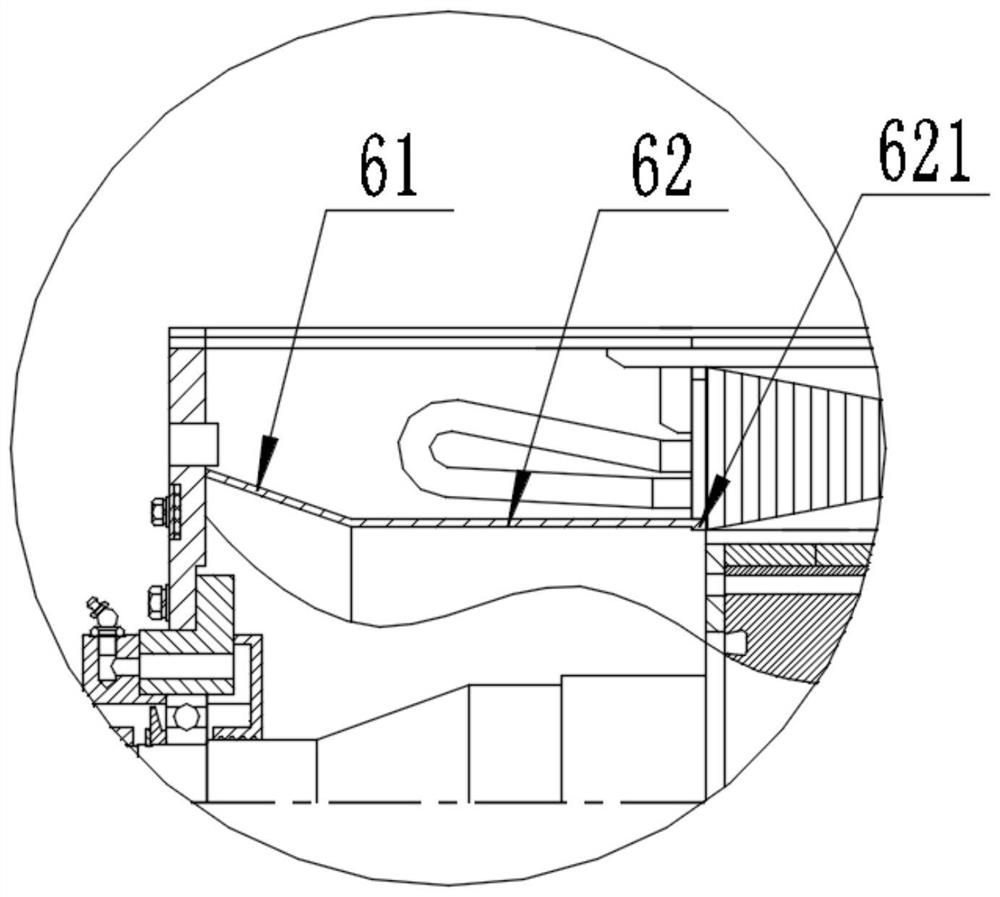

Semi-closed permanent magnet motor cooling system

ActiveCN111953124AImprove power densityHigh Reliability DesignMagnetic circuit rotating partsMagnetic circuit stationary partsForeign matterElectric machine

The invention belongs to the technical field of motor cooling systems, and provides a semi-closed permanent magnet motor cooling system in order to solve the problems that the cooling effect cannot beguaranteed, and no scrap iron or dust enters a strong magnetic rotor of a motor under the condition that the operation environment of the motor is severe. The system comprises a rotor, a rotating shaft, a casing, a stator core, a stator winding, an air inlet hole, an air outlet hole and a rotor sleeve structure, and the rotor sleeve structure sleeves the rotor to isolate the rotor from a stator;and the air inlet hole and the air outlet hole separately penetrate through an end cover arranged on the casing. In the working process, the external cooling air is guided in through the air inlet hole, flows through the stator winding at the end part of one side of the motor, the cooling channel on the stator iron core and the stator winding at the end part of the other side of the motor and thenflows out through the air outlet hole so as to cool the semi-closed permanent magnet motor. According to the present invention, foreign matters can be prevented from entering the rotor, and the cooling effect of the motor is not affected.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

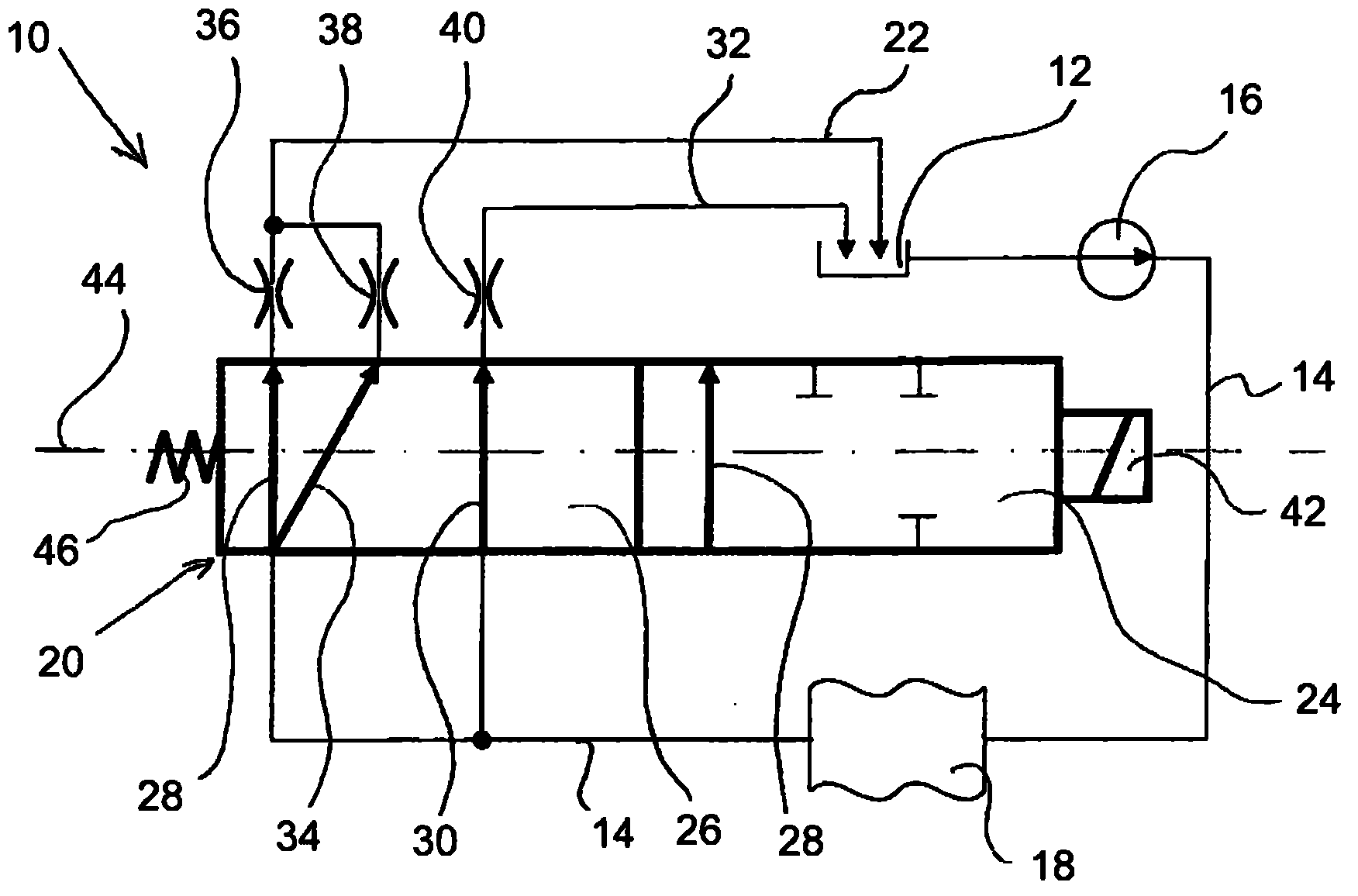

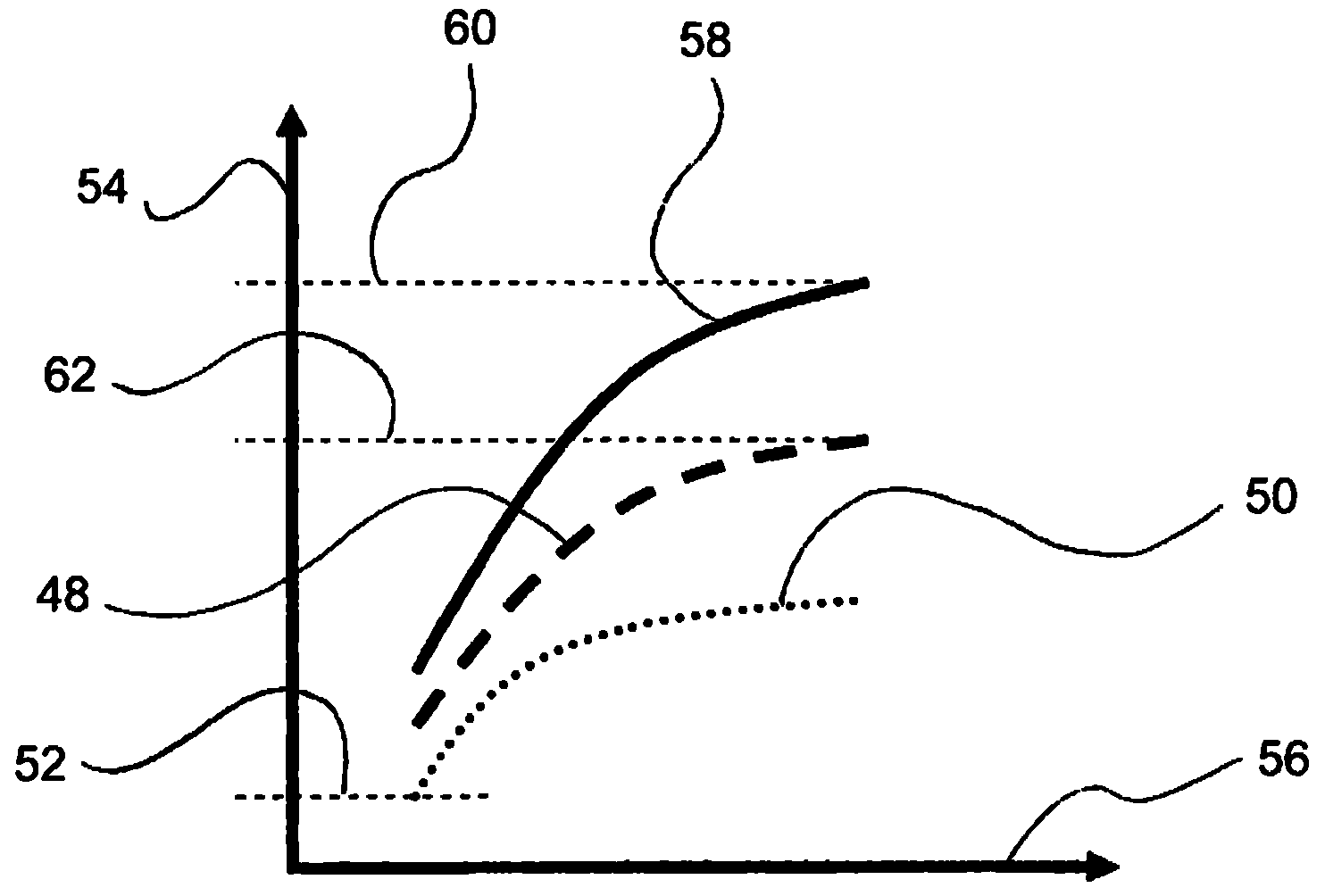

Fluid supply system and method of operating a fluid supply system

InactiveCN102422057AMass flow assuranceStop frictionGear lubrication/coolingGearing controlEngineeringLubrication

A fluid supply system (10) for cooling and lubricating a transmission of an automobile, comprising a cooling channel (14) and a lubrication channel (22).The lubrication channel (22) communicates with the cooling channel (14) via a shift valve (20), wherein the shift valve (20) is adapted to provide at least a first valve status, by which the cooling channel (14) is connected to the lubrication channel (22) via only one first valve path (28), and a second valve status, by which the cooling channel (14) is connected to the lubrication channel (22) via at least the first valve path (28) and by which the cooling channel (14) is connected in addition via a second valve path (30) to a bypass channel (32) bypassing the lubrication channel (22).

Owner:GM GLOBAL TECH OPERATIONS LLC

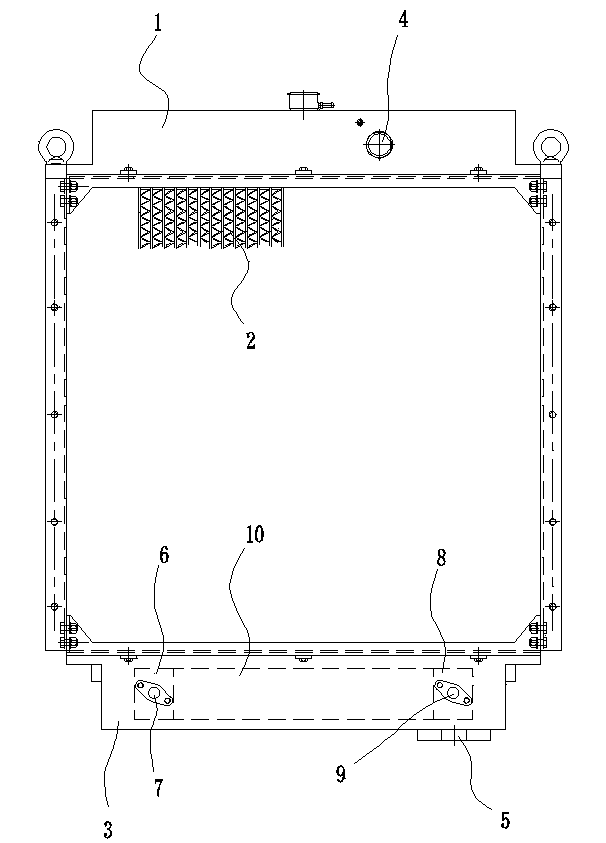

Efficient and energy-saving heat exchanger based on embedded technology

InactiveCN103422968AFit closelySave installation spaceMachines/enginesEngine cooling apparatusEmbedded technologyEngineering

The invention discloses an efficient and energy-saving heat exchanger based on an embedded technology. The efficient and energy-saving heat exchanger based on the embedded technology comprises a radiator, wherein the radiator is composed of an upper sealing head, a heat dissipation core and a lower sealing head, a first inlet for a medium to be cooled is formed in the upper sealing head, a first outlet for the medium to be cooled is formed in the lower sealing head, a auxiliary heat exchanger is arranged in a cavity of the lower sealing head, a auxiliary heat dissipation core of the auxiliary heat exchanger is horizontally arranged, a left sealing head of the auxiliary heat dissipation core is provided with a second inlet for the medium to be cooled, and a right sealing head of the auxiliary heat dissipation core is provided with a second outlet for the medium to be cooled. According to the efficient and energy-saving heat exchanger based on the embedded technology, waste heat produced after the medium is cooled can be effectively used, the heat exchange efficiency is improved, and the energy is saved.

Owner:WUXI YUDA HEAT EXCHANGER

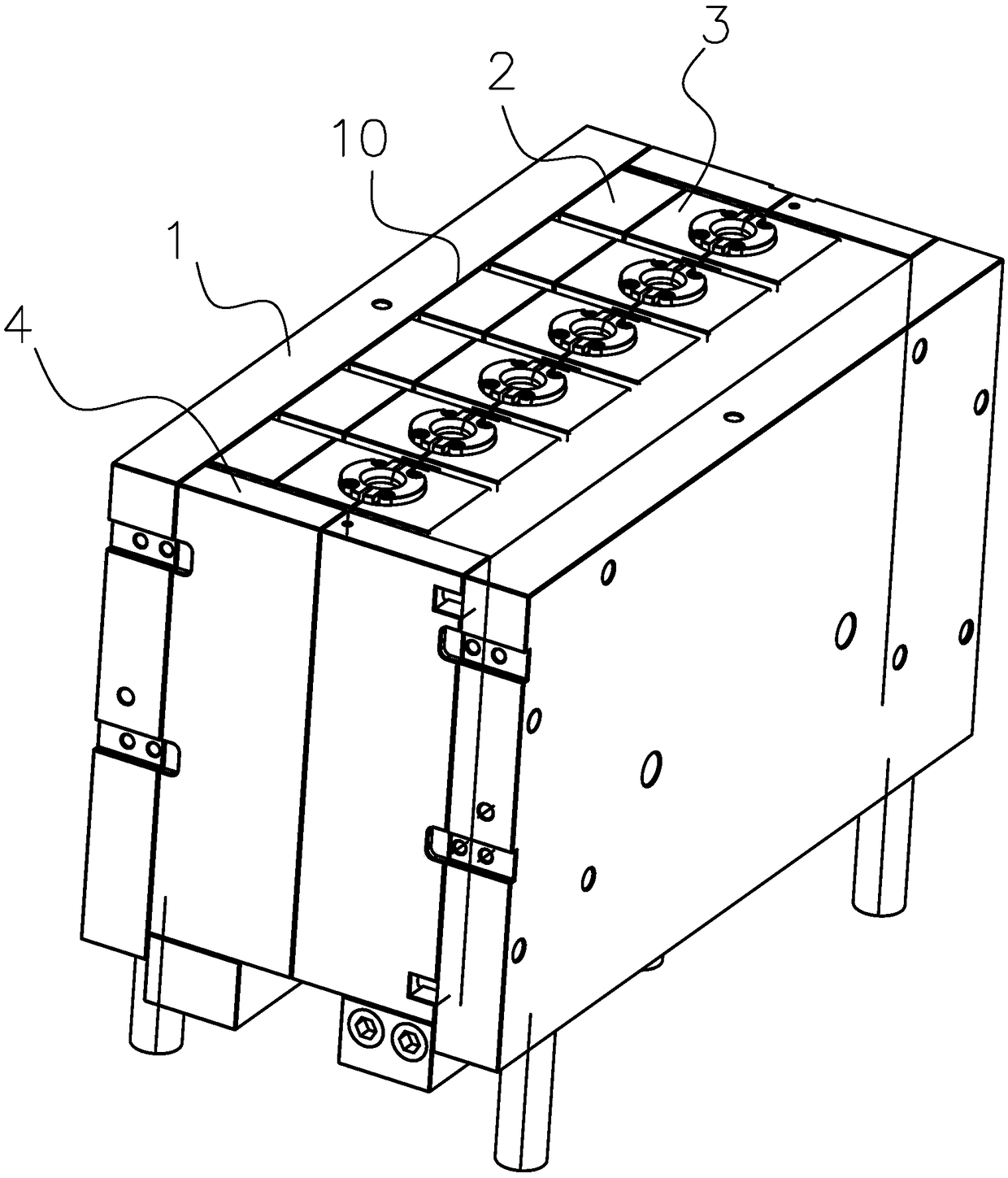

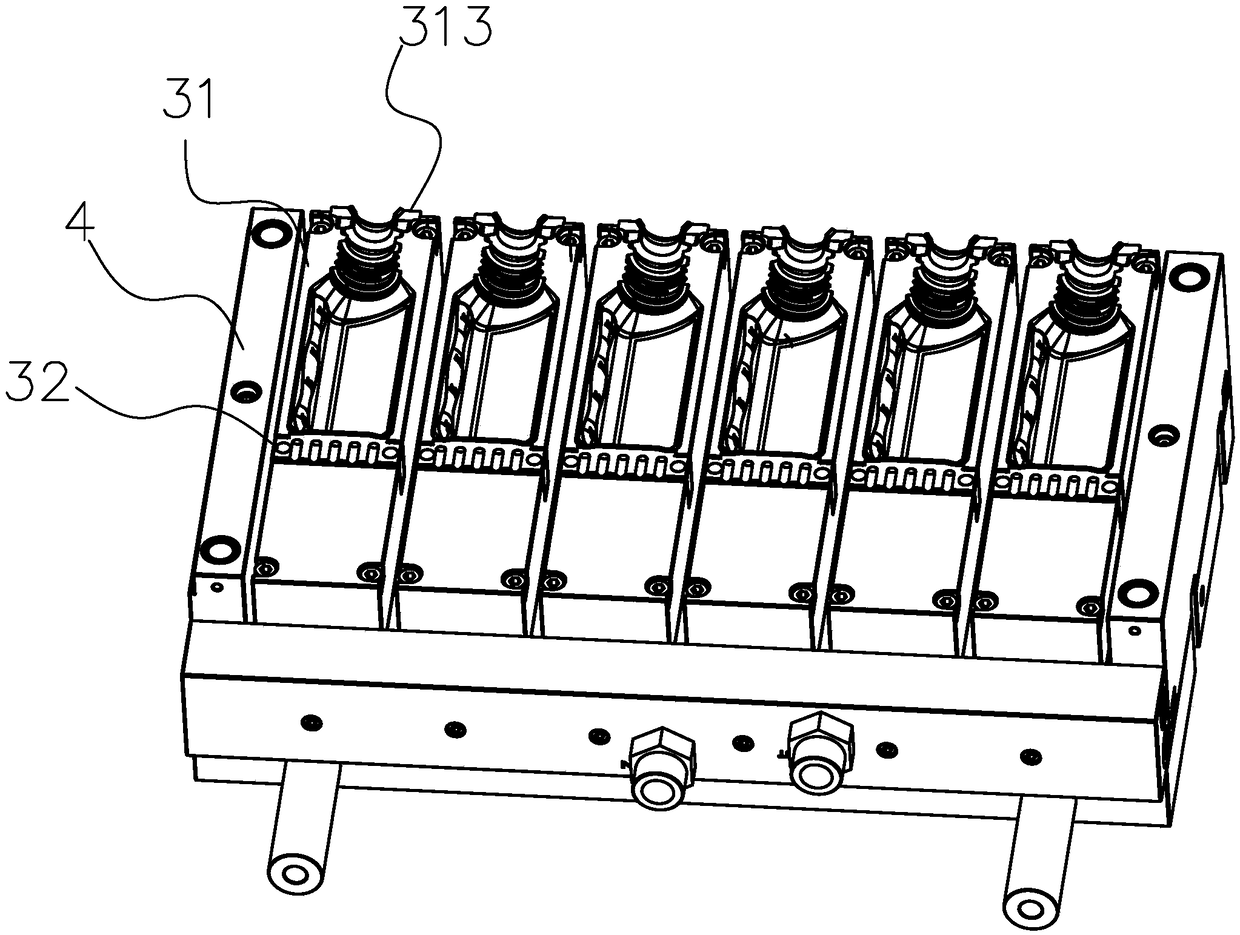

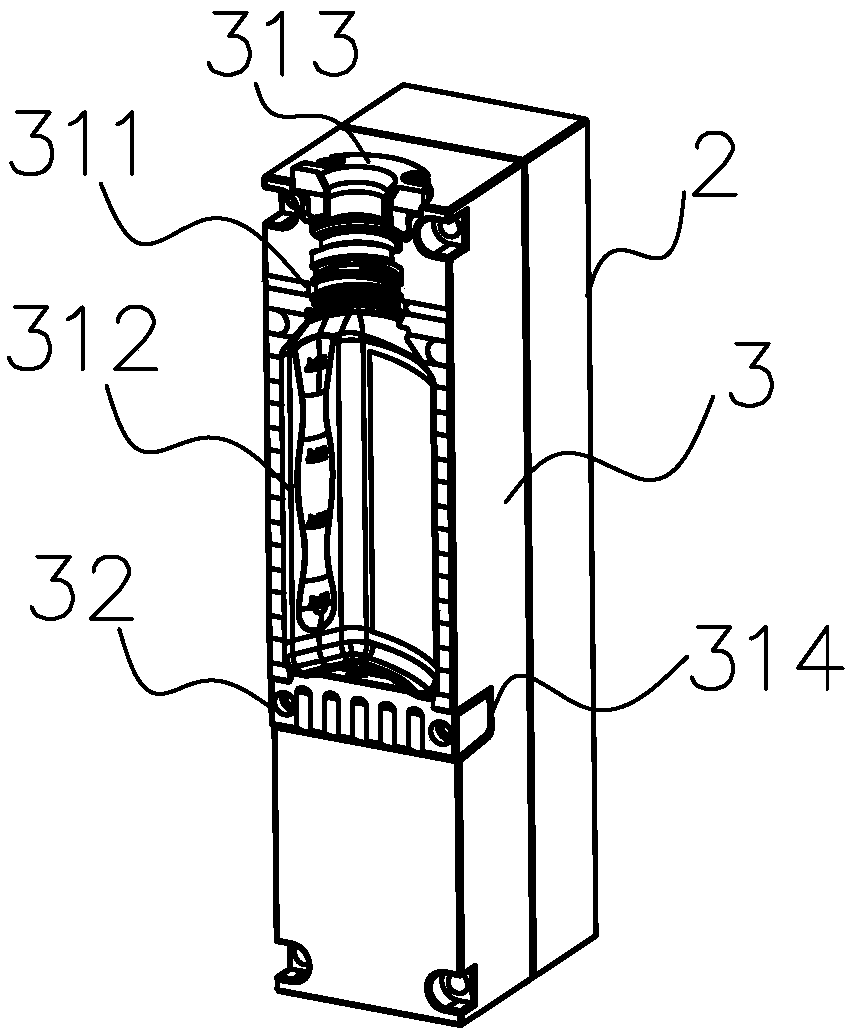

Combined cavity blow molding die

PendingCN109080109ATighten the sealReduce adverse effectsDomestic articlesHollow articlesBlow moldingCooling effect

The invention relates to the technical field of blow molding, in particular to a combined cavity blow molding die. The combined cavity blow molding die comprises mutually independent cavity modules, mutually independent cooling modules and die bottom plates. The cooling modules are mounted on the die bottom plates, the cavity modules are mounted on the cooling modules, and the cavity modules, thecooling modules and the die bottom plates are all disposed in pairs. The combined cavity blow molding die is provided with the mutually independent cavity modules, and has the advantages of flexible configuration, good cooling effect, good production efficiency and good product quality.

Owner:HANGZHOU HESHENG PLASTIC PROD CO LTD

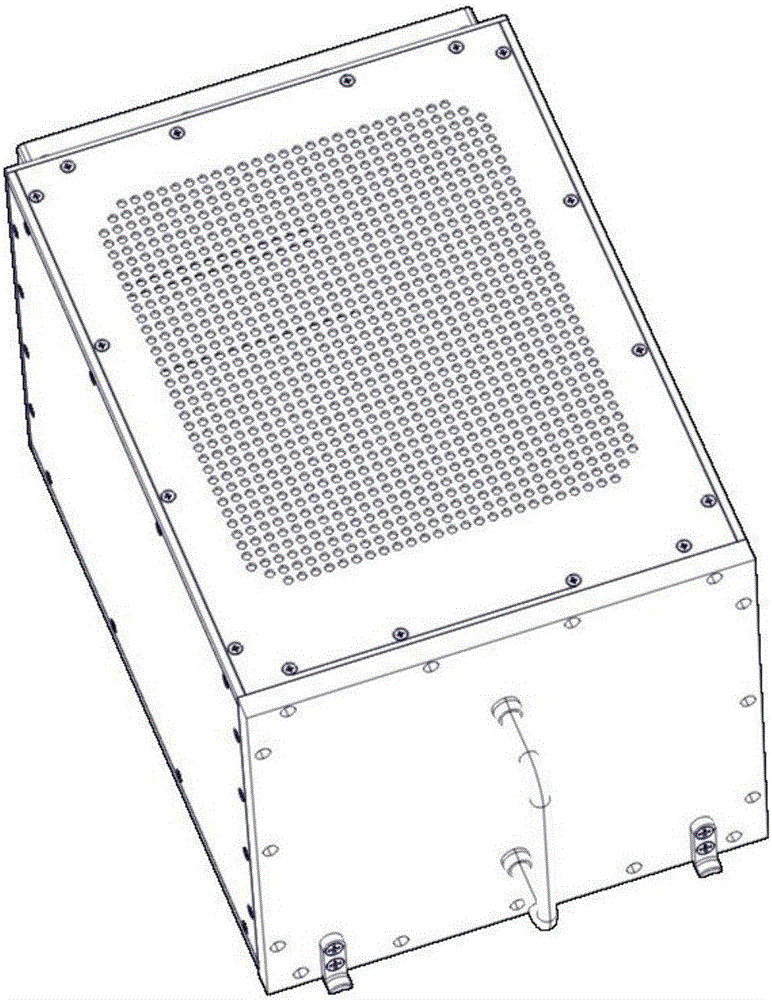

Forced air cooling chassis resisting marine atmospheric environment

InactiveCN106535566AAvoid dustAvoid corrosionCooling/ventilation/heating modificationsEnvironmental resistanceAtmospheric air

The invention belongs to the forced air cooling technology of an electronic device, and in particular relates to a forced air cooling chassis resisting marine atmospheric environment. Electronic components on the existing forced air cooling chassis directly contact cooling gas and outside atmosphere, and suffer to dust and corrosion after long-term use. Excessive dust affects the cooling effect of the device. The degradation of the three-proofing performance of the chassis is caused by corrosion. According to the invention, the chassis structure is redesigned; the chassis main body in a closed structure is composed of a front panel, a rear panel, a left cooling plate, a right cooling plate, a top plate and a bottom plate; the chassis main body is covered by an upper cover plate, a lower cover plate, a right side plate and a left side plate; the left cooling plate and the right cooling plate are provided with cooling air passages which are communicated with the upper cover plate and the lower cover plate; and on the premise that ventilation, cooling and other performances of the electronic device are ensured, the marine atmospheric environmental resistance of the electronic device is improved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

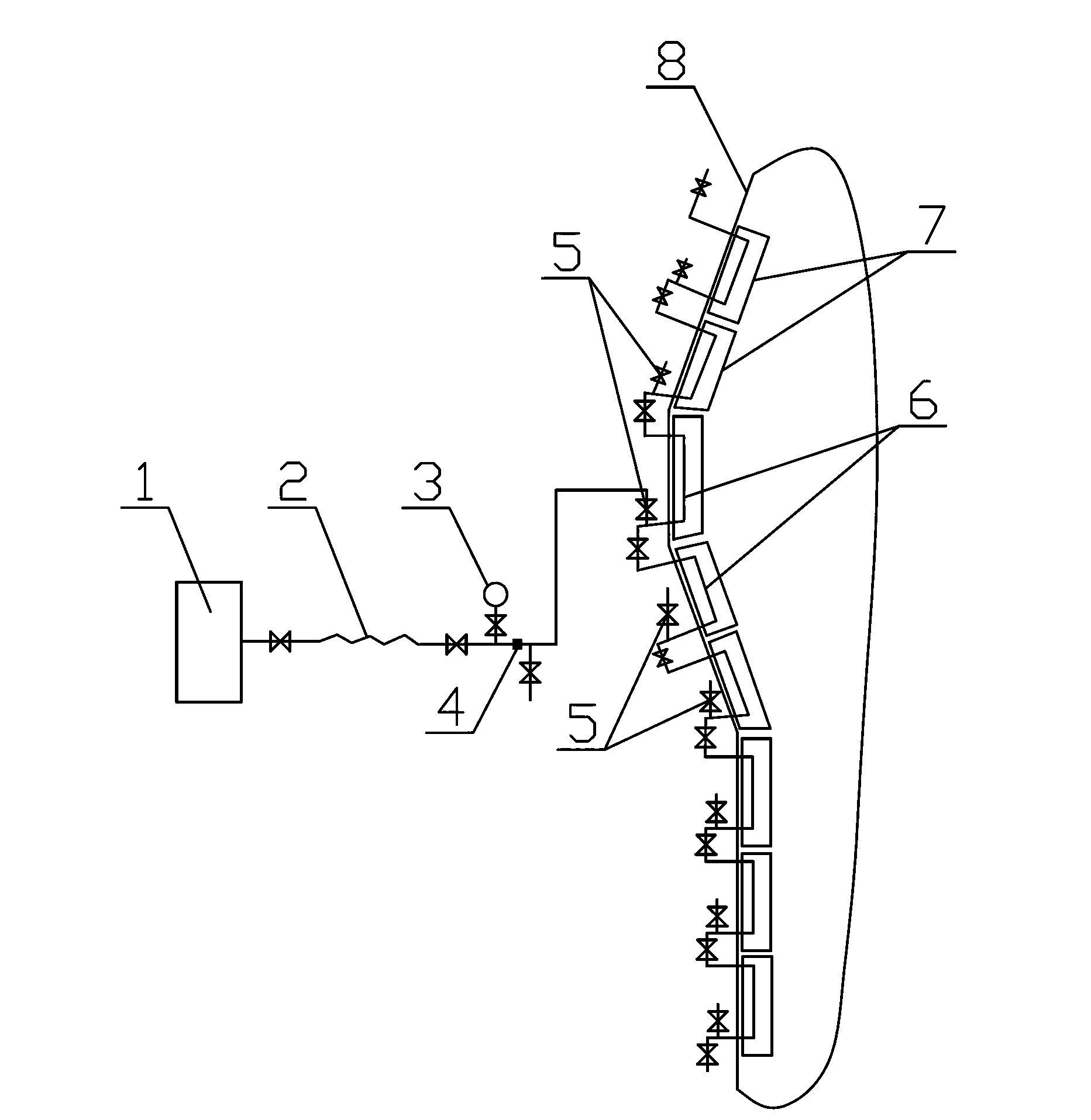

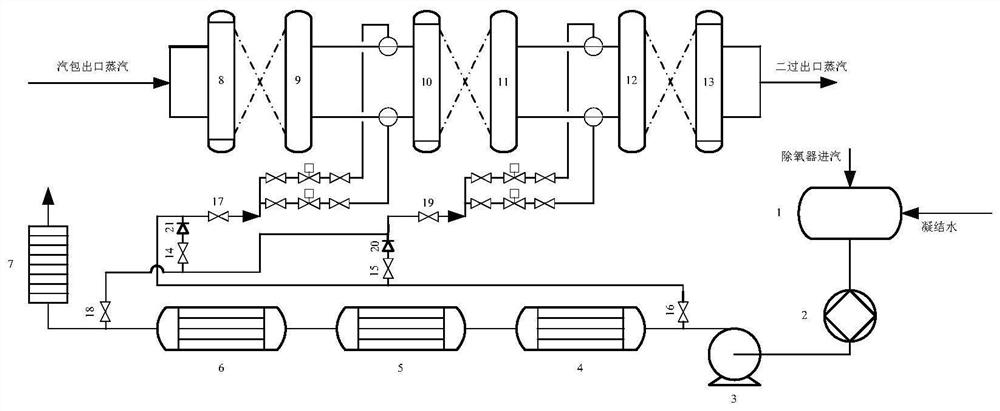

Two-stage superheater desuperheating water system capable of independently taking water

PendingCN112303613AGuaranteed safe operationIncrease the differential pressureSuperheating controlWarm waterCooling effect

The invention discloses a two-stage superheater desuperheating water system capable of independently taking water. The two-stage superheater desuperheating water system comprises a deaerator, a waterfeeding pump, a third high-pressure heater, a first main pipe electric gate valve, a second high-pressure heater, a first high-pressure heater, an economizer, a second main pipe electric gate valve, afirst electric contact gate valve, a first contact main pipe check valve, a second-stage water supply system main pipe electric gate valve in an independent water taking mode, a first-stage water supply system main pipe electric gate valve in an independent water taking mode, a second electric contact gate valve, a second contact main pipe check valve, a platen superheater inlet header, a second-stage superheater inlet header, a steam pocket outlet steam pipeline, a first-stage superheater inlet header, a first-stage superheater outlet header, a platen superheater outlet header, a second-stage superheater outlet header and a steam output pipeline. The system can guarantee the cooling effect of superheated steam water spraying, the spray cooling effect is good, and the operation workload of operators is small.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

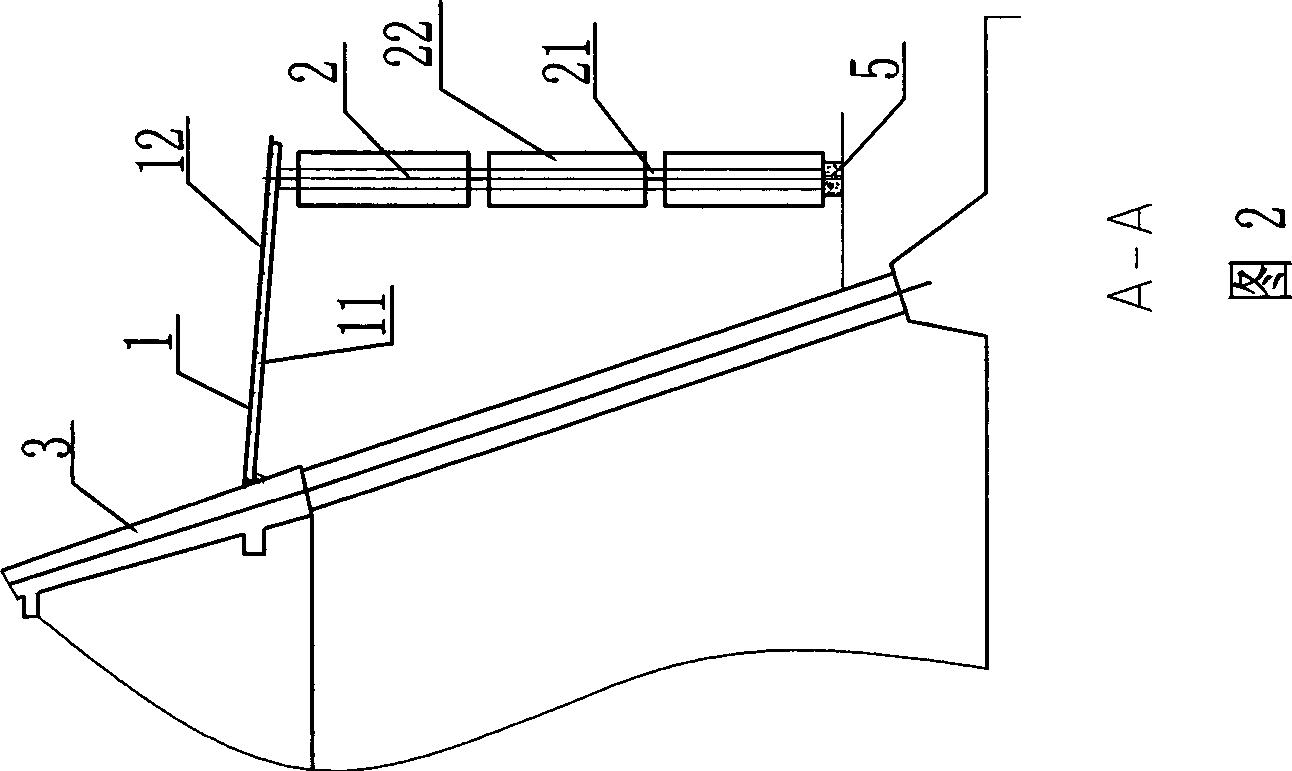

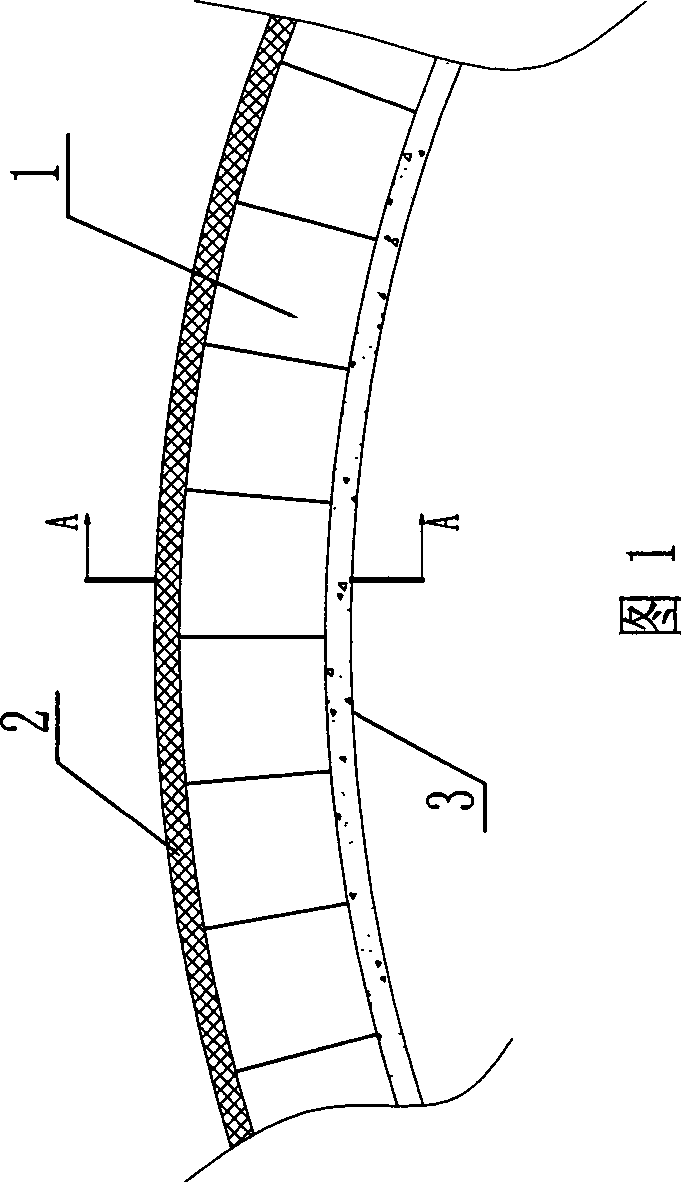

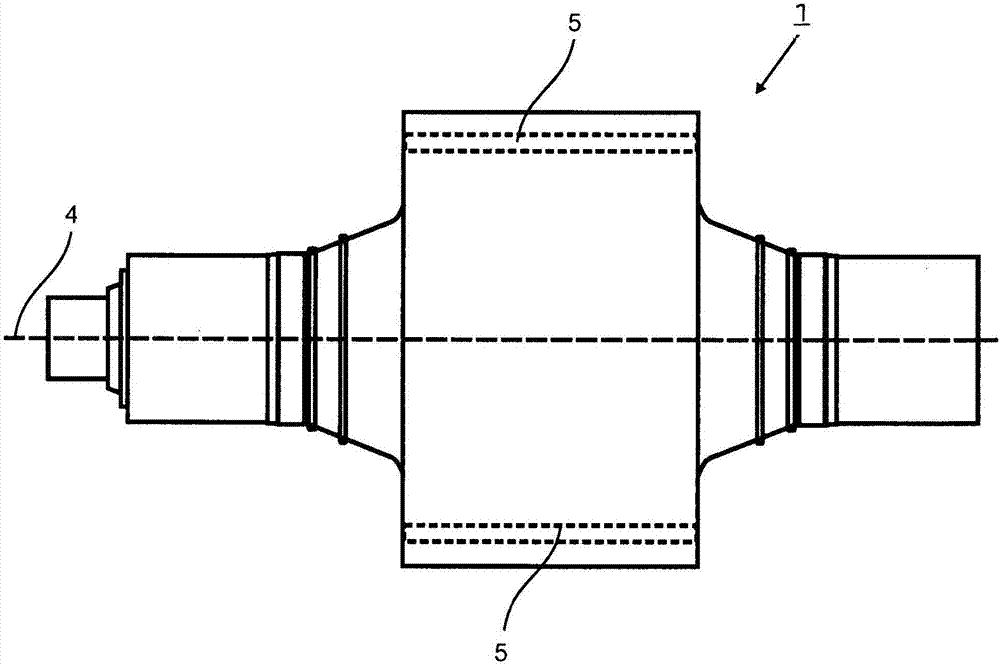

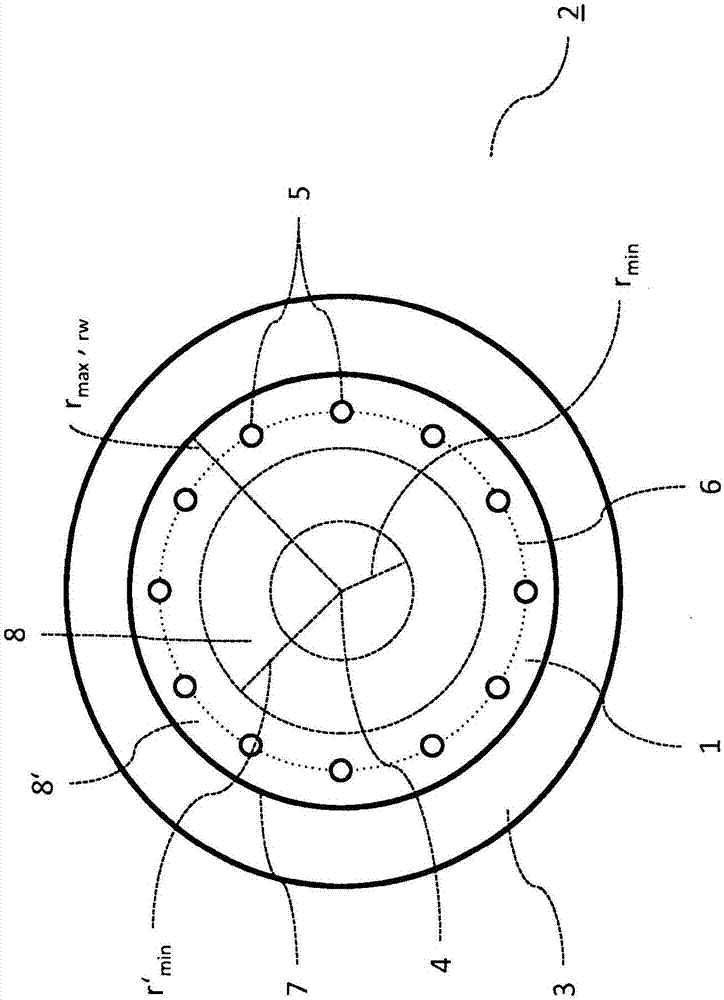

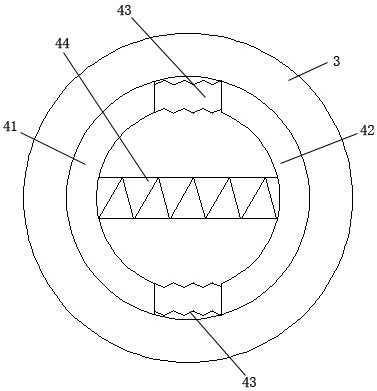

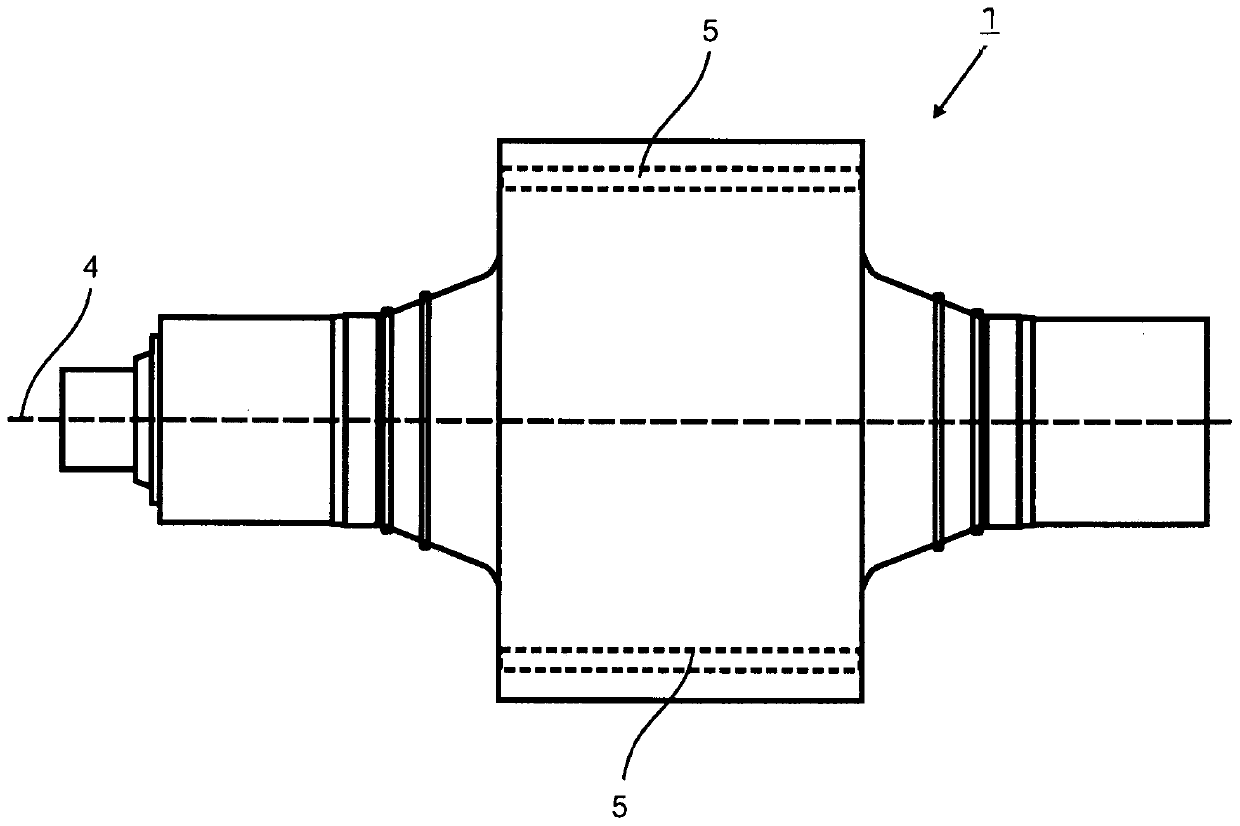

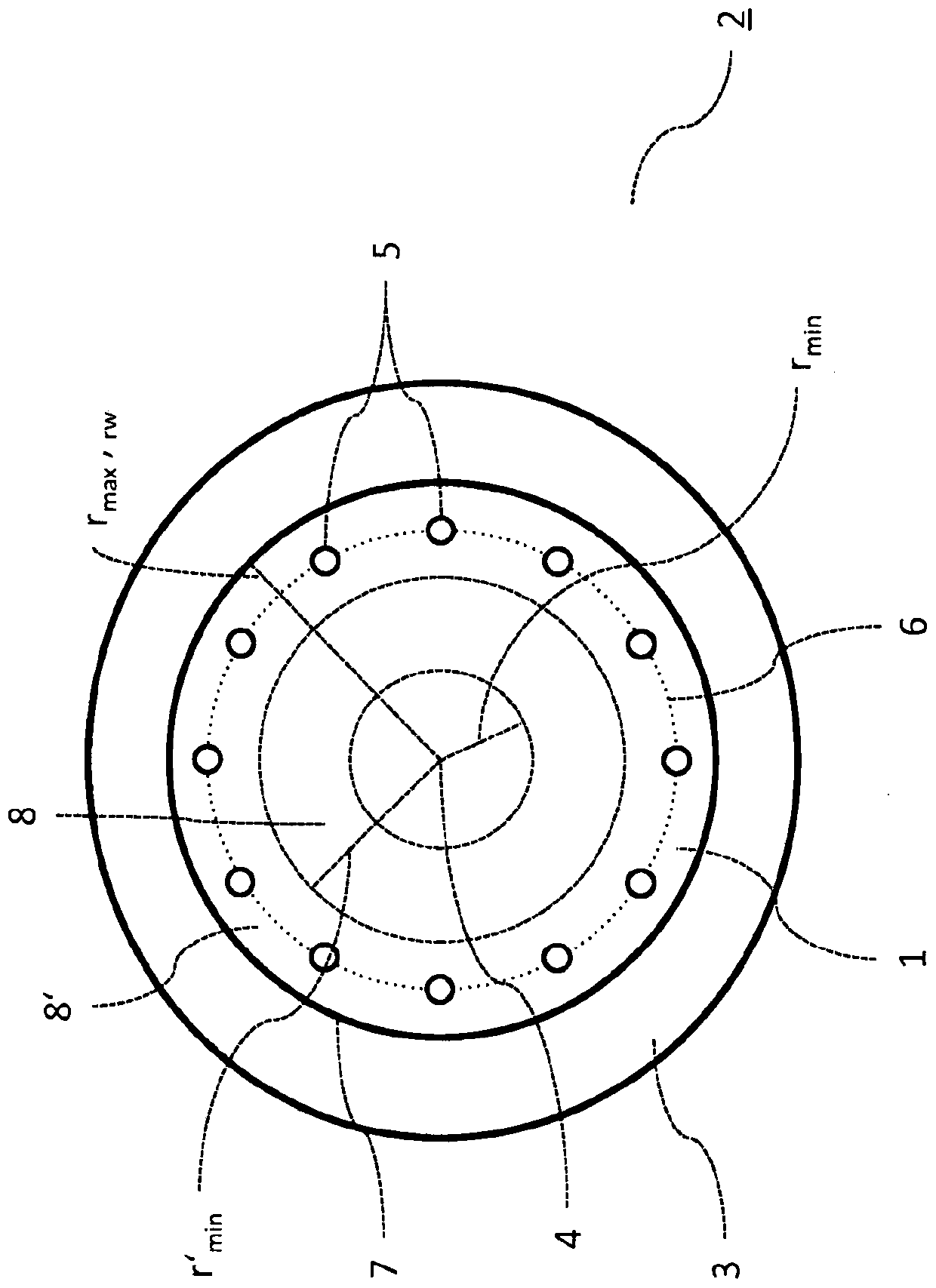

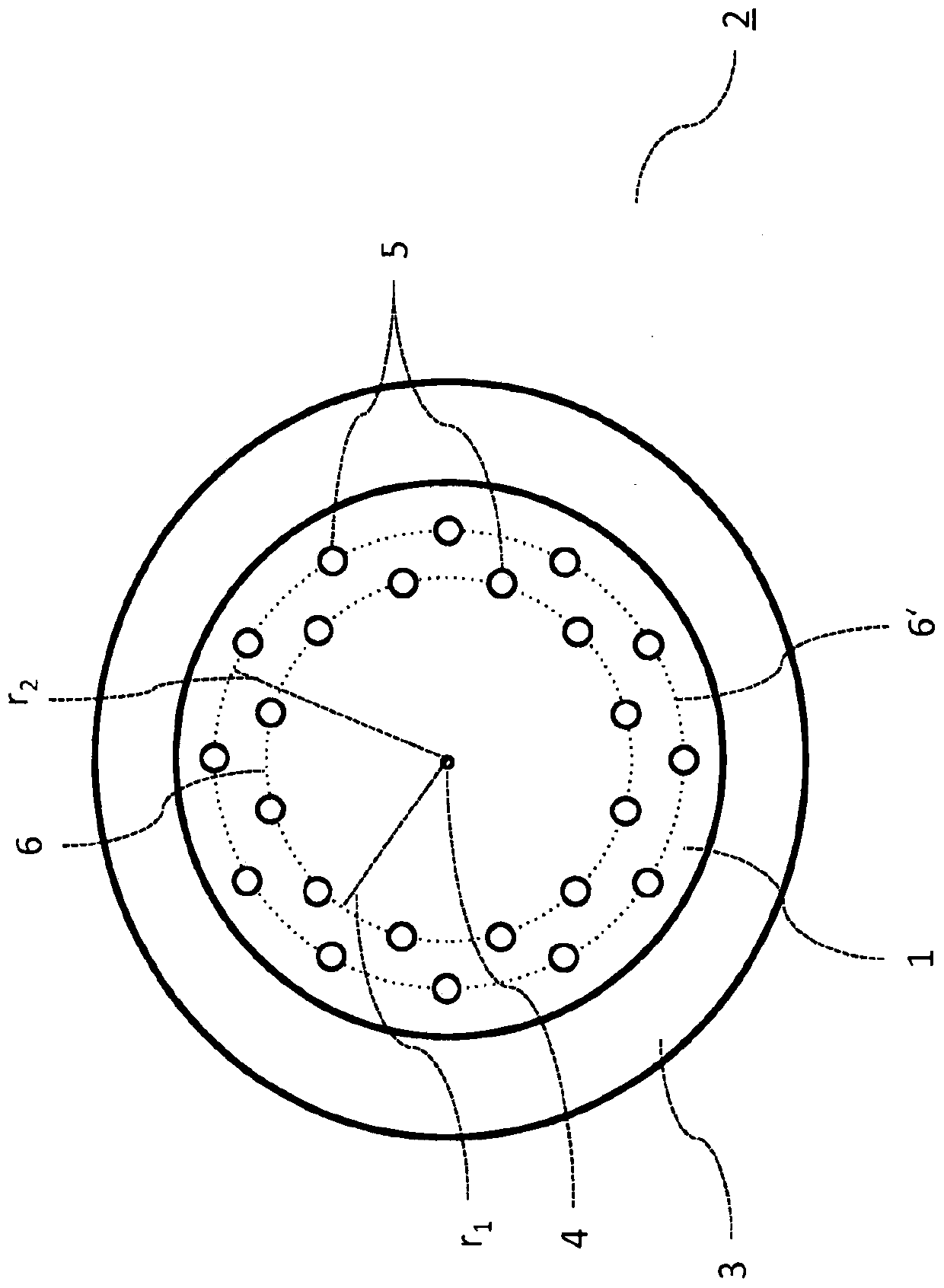

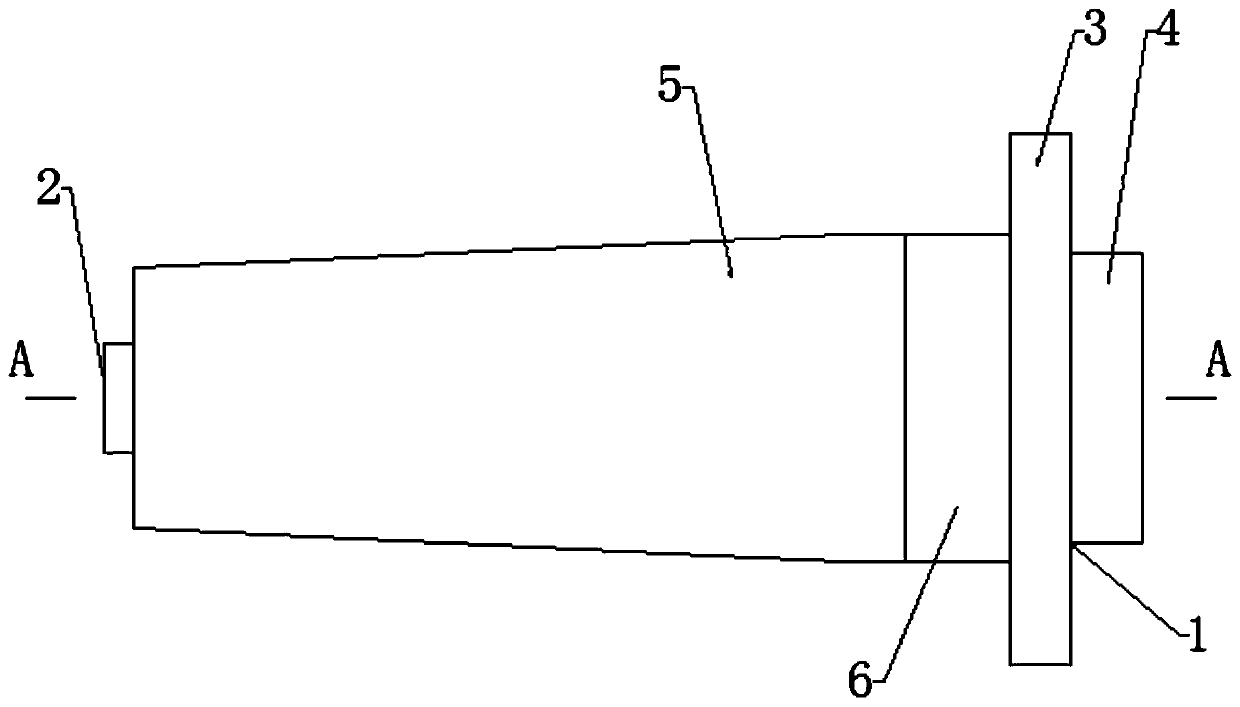

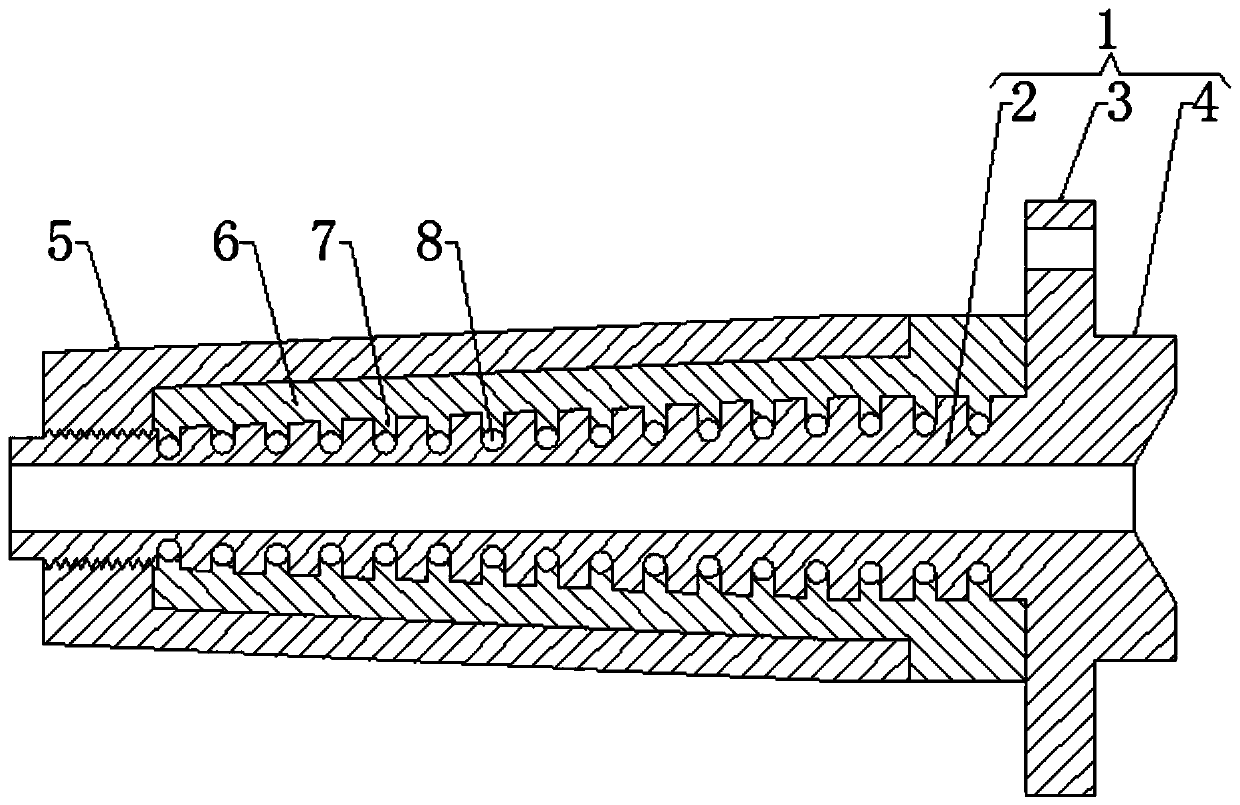

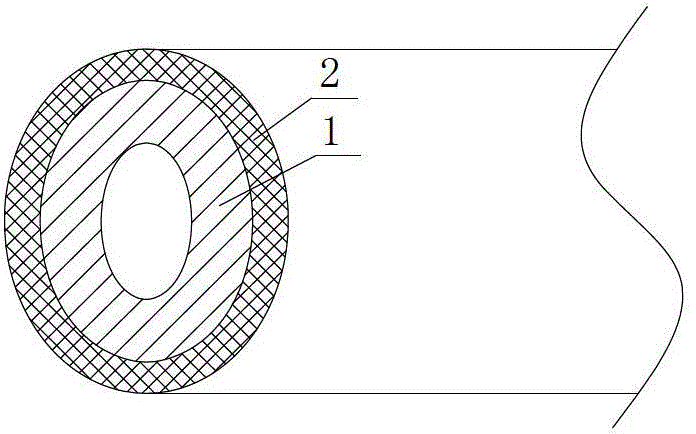

Grinding roller and methods for pulling off a strap and shrinking a strap onto the shaft of the grinding roller

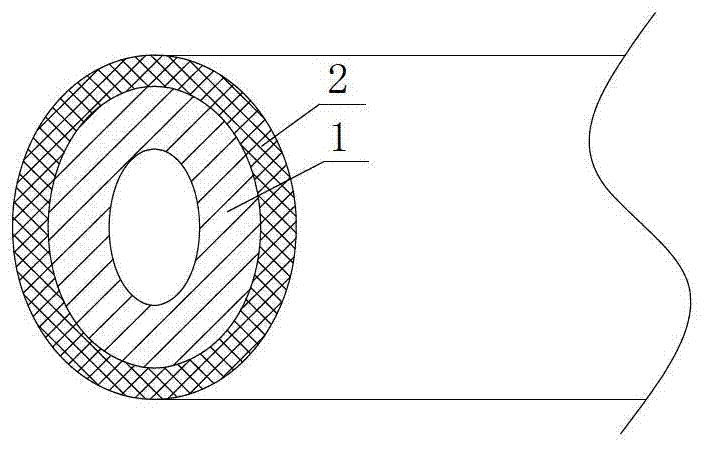

InactiveCN107206385ACool evenlyDoes not affect cooling effectGrain treatmentsWear resistantEngineering

The invention relates to a grinding roller (2) of a high-pressure roller press, comprising a shaft (1) and a wear-resistant strap (3), wherein the strap (3) is frictionally shrunk onto the shaft (1). The invention further relates to a method for separating a strap (3) and a shaft (1) in the case of such a grinding roller (2) and to a method for frictionally connecting a strap (3) and a shaft (1) in order to form such a grinding roller (2). According to the invention, the shaft (1) has a plurality of cooling bores (5) passing through in the axial direction for gaseous or liquid coolant to flow through said cooling bores, wherein the cooling bores (5) are arranged in the outer region of the shaft (1). Furthermore, in order to separate the strap (3) from the shaft (1), according to the invention, the strap (3) is heated by supplying heat from outside, the shaft (1) is simultaneously cooled by means of a coolant flowing through the cooling bores (5), and the strap (3) is pulled off from the shaft (1) in the longitudinal direction.

Owner:KHD HUMBOLDT WEDAG GMBH

Water-cooling and air-cooling electronic power heat dissipation device

InactiveCN111741651ADoes not affect cooling effectFit tightlyCooling/ventilation/heating modificationsThermodynamicsEngineering

Owner:江苏海鼎电气科技有限公司

Series type air cylinder cover water channel structure

InactiveCN105332812ADoes not affect cooling effectReduce in quantityCylinder headsCylindersWater channelCooling effect

The invention provides a series type air cylinder cover water channel structure which comprises multiple cylinder covers. The interior of each cylinder cover is provided with a water passage. The positions, used for supporting mold cores, at the two ends of each water passage are provided with series water gaps. The water passages of every two adjacent cylinder covers are communicated through the series water gaps in the corresponding two ends. Annular grooves are formed in the outer edges of the series water gaps. O-shaped rubber sealing rings are embedded in the annular grooves. When the cylinder covers are assembled together, a general series water return channel is formed. The series type air cylinder cover water channel structure has the following beneficial effects that the general water return channel is naturally formed through the water passages in the cylinder covers, the number of components is reduced, cost is saved, compactness is improved, and the installation and operation intensity is lowered. Through reasonable design, the water return channel arranged in the cylinder covers and cooling water sleeves of the cylinder covers are formed into a whole, extra occupation of the internal spaces of the cylinder covers is avoided, and the cooling effect of the cylinder covers cannot be affected.

Owner:CHINA NORTH ENGINE INST TIANJIN

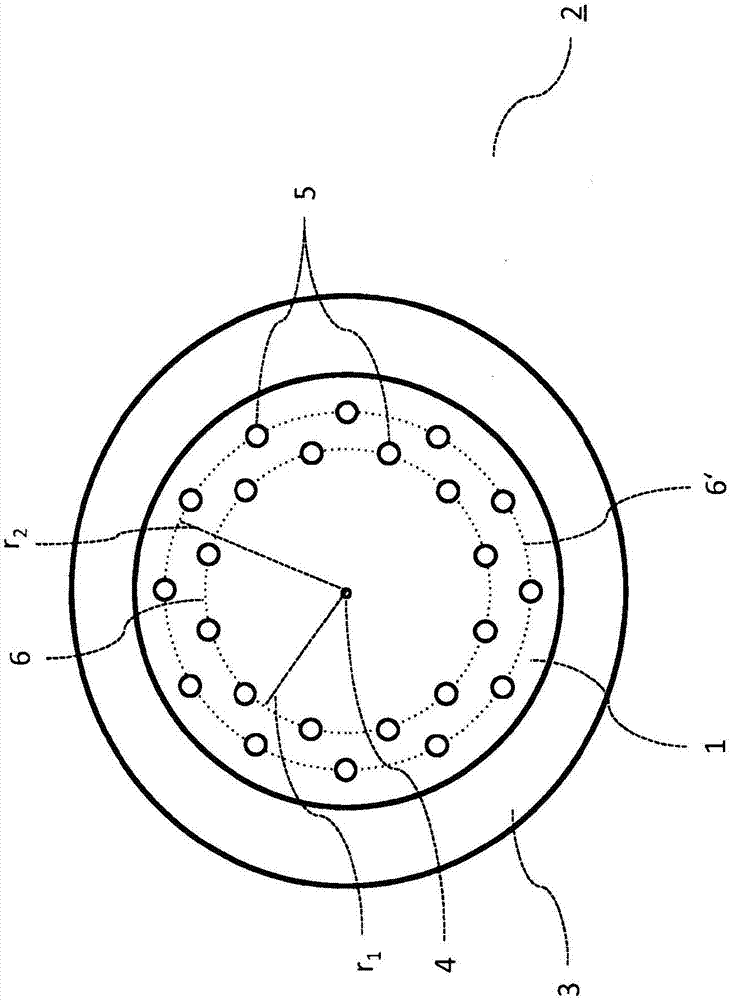

Drum, method for removing a tire and method for shrink fitting a tire onto the shaft of a roller

InactiveCN107206385BCool evenlyDoes not affect cooling effectGrain treatmentsShrink-fittingCoolant flow

The invention relates to a roller (2) of a high-pressure roller press, said roller comprising a shaft (1) and a wear-resistant rim (3), wherein said rim (3) is heat-fitted in a force-locking manner onto axis (1). Furthermore, the invention relates to a method for separating the tire (3) and the shaft (1) in such a roller (2) and a method for force-fitting the tire (3) and the shaft (1) Ground is connected into the method for this roller (2). According to the invention, the shaft (1) has a plurality of cooling holes (5) passing through in the axial direction for the flow of gaseous or liquid coolant, wherein the cooling holes (5) are provided In the outer area of the axis (1). In addition, in order to separate the rim (3) from the shaft (1), it is provided that the rim (3) is heated by a heat supply from the outside, whereby the alignment of the shaft (1) is achieved by means of coolant flowing through the cooling holes (5). cooling; and remove the tire (3) from the shaft (1) in the longitudinal direction.

Owner:KHD HUMBOLDT WEDAG GMBH

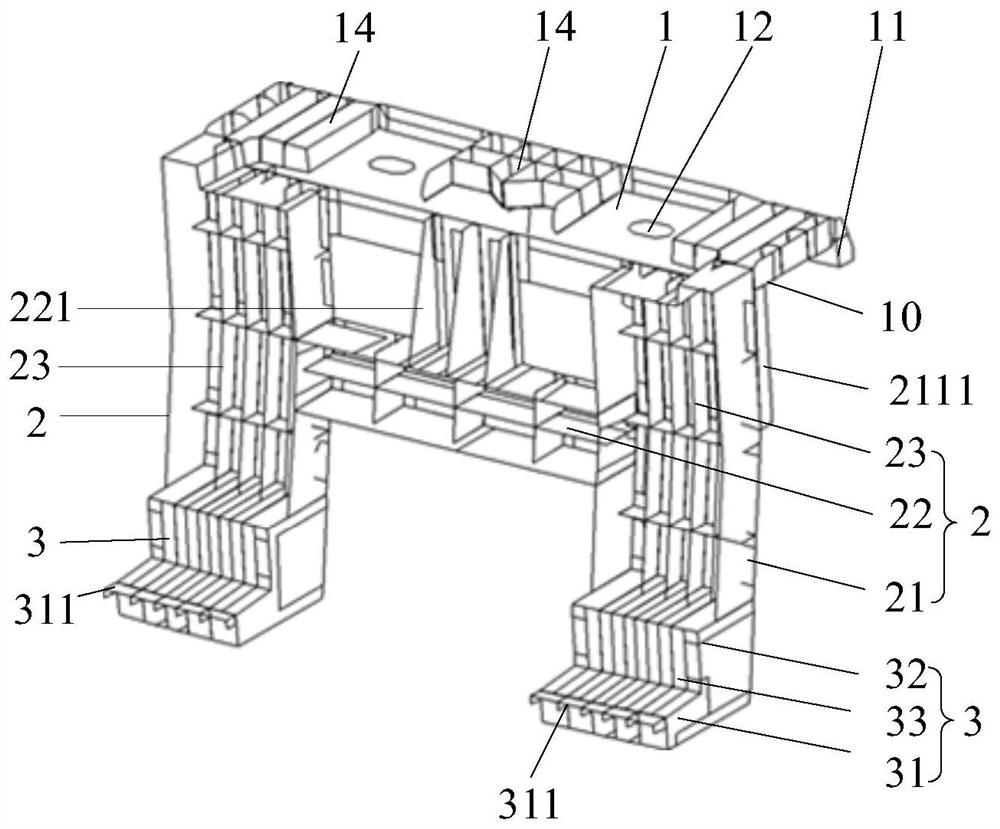

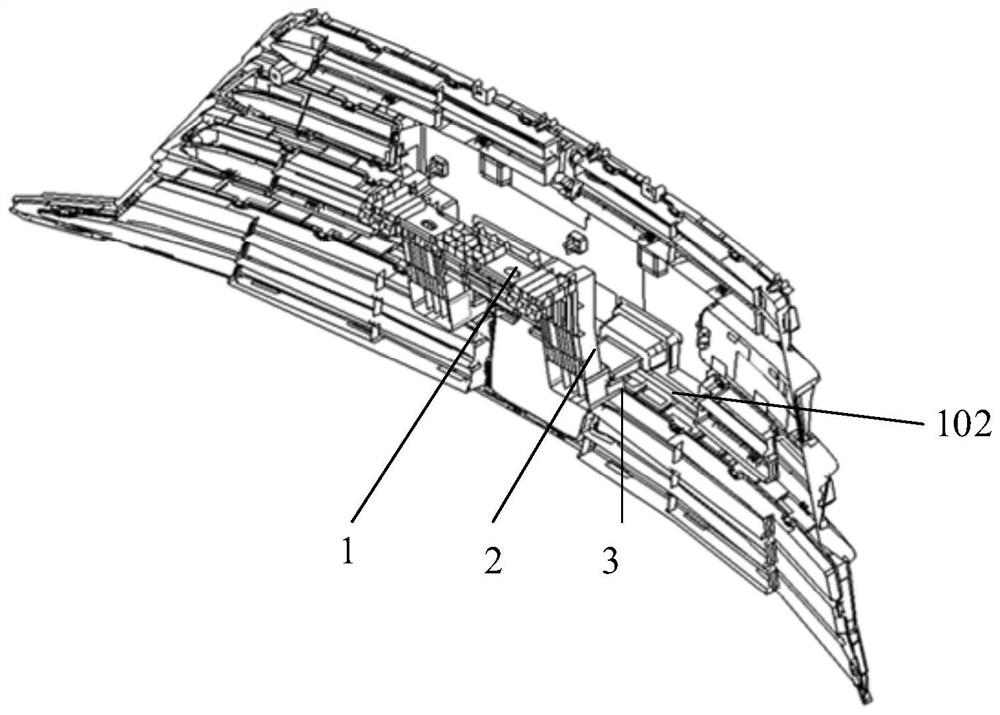

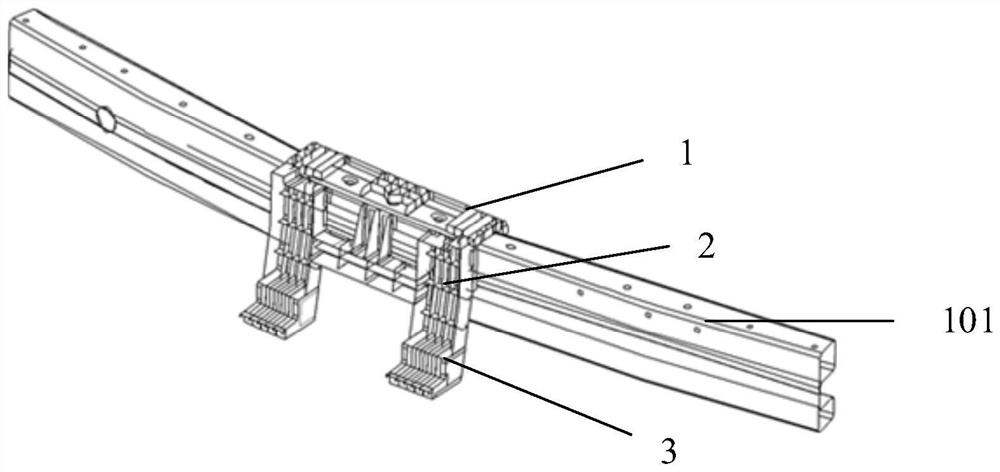

front support device

ActiveCN112373424BAchieve connectionPrevent sinkingPedestrian/occupant safety arrangementBumpersCar manufacturingStructural engineering

Owner:CHERY AUTOMOBILE CO LTD

Device capable of heating sprue bush in plastic mold

The invention relates to the field of plastic molds, and discloses a device capable of heating a sprue bush in a plastic mold. The device comprises the sprue bush, and an assembling part, a fixed partand a butt joint part are arranged on the sprue bush. The assembling part is sleeved with a mounting sleeve, and a heat preservation and insulation layer is arranged between the assembling part and the mounting sleeve. The outer surface of the mounting sleeve is a conical face, and a plurality of grooves are formed in the assembling prat. Heat exchange wires are laid in the grooves. The multiplegrooves are machined in the outer side of the assembling part, then the heat exchange wires are laid in the grooves, the heat exchange wires are powered on to generate heat to heat the assembling part, and therefore molten plastic materials flowing through the assembling part are kept at a high temperature and are kept at a proper temperature until the molten plastic materials enter a mold cavity;and the problems that a flow channel is blocked, and a product has glue missing, shrinkage, craze discoloring and other defects are avoided, the procedure of additionally correcting the product is omitted, and the production efficiency is improved.

Owner:龙锋

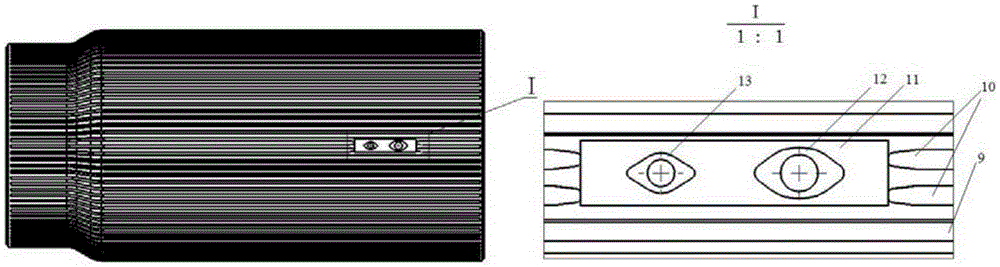

Temperature and pressing measuring device on water-cooling wall surface of combustion chamber and machining method thereof

ActiveCN105403243ASmall flow resistanceDoes not affect cooling effectMeasurement devicesCombustion chamberCooling effect

The invention discloses a temperature and pressing measuring device on a water-cooling wall surface of a combustion chamber and a machining method thereof. The device comprises a pressure-measuring pipe, a temperature-measuring pipe, a temperature-measuring joint nozzle, and a pressure-measuring joint nozzle, the temperature-measuring joint nozzle and the temperature-measuring pipe are integrally welded, the pressure-measuring joint nozzle and the pressure-measuring pipe are integrally welded, the temperature-measuring pipe and the pressure-measuring pipe are welded with a combustion chamber inner wall, a combustion chamber interlayer, and a block together, and the block and a cavity arranged on a combustion chamber jacket are welded together. The machining method includes: finishing of the external surface of the combustion chamber inner wall is performed; temperature-measuring holes and pressure-measuring holes are machined on the combustion chamber inner wall, the combustion chamber interlayer, and the block; the temperature-measuring pipe and the pressure-measuring pipe are welded with the combustion chamber inner wall and the combustion chamber interlayer together; the temperature-measuring pipe and the pressure-measuring pipe penetrate through the temperature-measuring hole and the pressure-measuring hole on the block and are welded with the block together, and the block is welded with the cavity on the combustion chamber jacket together. According to the device and the machining method thereof, the cooling effect of a measuring point area and the structural intensity of the combustion chamber are not affected, and the leakage of cooling media to the inner side of the combustion chamber and the outside of the combustion chamber interlayer is avoided.

Owner:NAT UNIV OF DEFENSE TECH

A kind of gear billet mold

The invention discloses a gear billet mold, which comprises a bottom mold base, a bottom mold, and a gear mold. The gear mold is provided with more than two tooth grooves, and a gear mold is installed on the bottom mold. The bottom mold base and the bottom mold The mold is integrated, and a side groove and a push rod are arranged between the bottom mold base and the bottom mold. The gap fit is adopted between the side groove and the push rod, and the side groove communicates with the cooling groove in the tooth groove. The rod and the side groove are co-fitted inside the bottom mold, and the side groove and the pressure chamber are in the same plane. The driving force generated by the push rod is pushed horizontally until it touches the connecting bump, and the air pressure inside the pressure chamber will be continuously squeezed, and the pressure chamber will be matched. The continuously squeezed pressure pushes upward the piston enclosed in the tooth groove cavity. The tooth groove closed by the piston and the steel plate mainly provides the shaping effect for the sawtooth of the gear, and when the piston pushes up, it is fixed in the tooth groove The inner sawtooth is brought out, and the pulling force is changed into a pushing force to realize that the sawtooth will not break on the mold when it is brought up.

Owner:中山市技佳传动科技有限公司

Rapid cooling and conveying device for immersed aluminum profile

The invention belongs to the technical field of cooling and conveying devices, and particularly relates to a rapid cooling and conveying device for an immersed aluminum profile. The device comprises arolling support part I, a rolling support part II, a lower cooling part and an upper cooling part. According to the device, cooling liquid in a cooling box body I is extracted through a water suctionpump I, and then is sprayed from an injection pipe, so as to achieve that the cooling liquid is ejected onto the lower surface of the aluminum profile, and cooling of the lower surface of the aluminum profile is achieved; at the same time, a liquid outlet pipe releases cooling liquid in a cooling box body II onto the upper surface of the aluminum profile, so as to achieve that the cooling liquidis blocked onto the aluminum profile between the liquid outlet pipe and a liquid extraction pipe through elastic sealing plates arranged on both sides, and the cooling liquid cools the upper surface of the aluminum profile; and during the process, the cooling liquid on the upper surface of aluminum alloy is constantly replaced, so as to ensure that the cooling speed of the aluminum profile is moreuniform, and the quality of the aluminum profile during the cooling process is improved.

Owner:林雪

Semi-enclosed permanent magnet motor cooling system

ActiveCN111953124BImprove power densityHigh Reliability DesignMagnetic circuit rotating partsMagnetic circuit stationary partsForeign matterElectric machine

The invention belongs to the technical field of motor cooling systems, and aims to solve the problem that the motor cannot not only ensure the cooling effect but also ensure that the strong magnetic rotor of the motor does not enter iron filings and dust in the case of a bad operating environment, and provides a semi-closed permanent magnet Motor cooling system, including rotor, rotating shaft, casing, stator core, stator winding, air inlet hole, air outlet hole and rotor sleeve structure, the rotor sleeve structure is sleeved on the outside of the rotor to isolate the rotor and stator; The air hole and the air outlet hole are respectively set through the end cover of the casing; during the working process, the external cooling air is introduced through the air inlet hole, and flows through the stator winding at the end of the motor side, the cooling channel on the stator core, After the stator winding at the other end of the motor, it flows out through the air outlet to cool the semi-closed permanent magnet motor. The invention can prevent foreign matter from entering the rotor without affecting the cooling effect of the motor.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

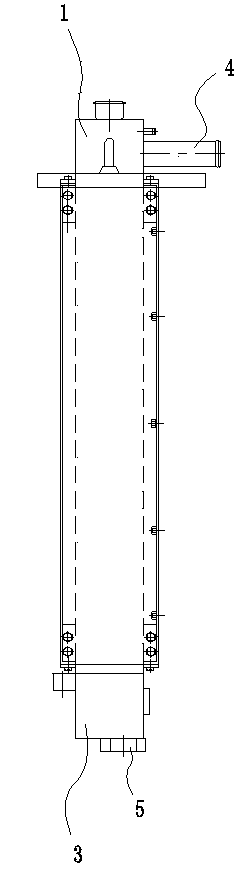

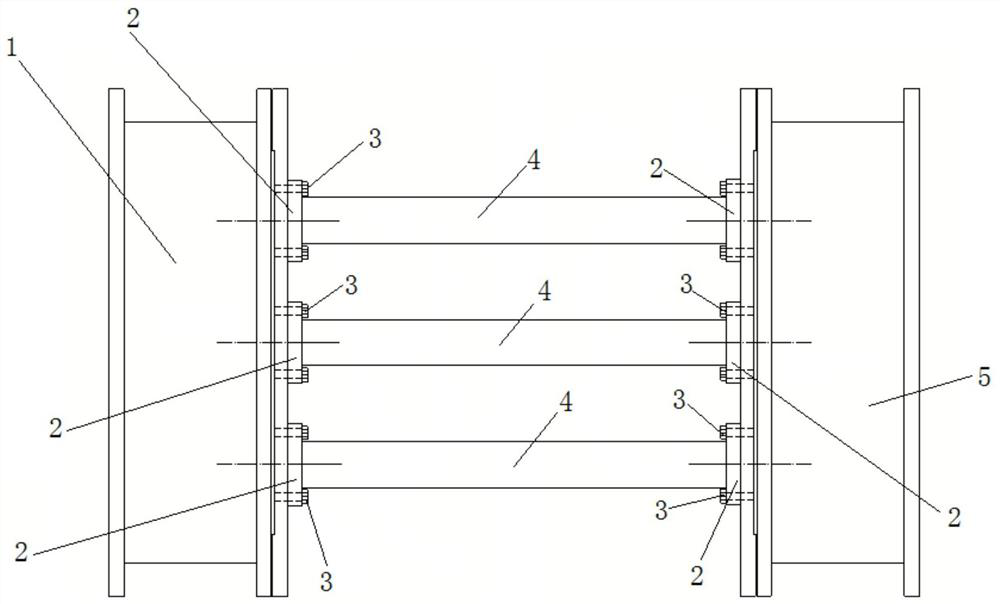

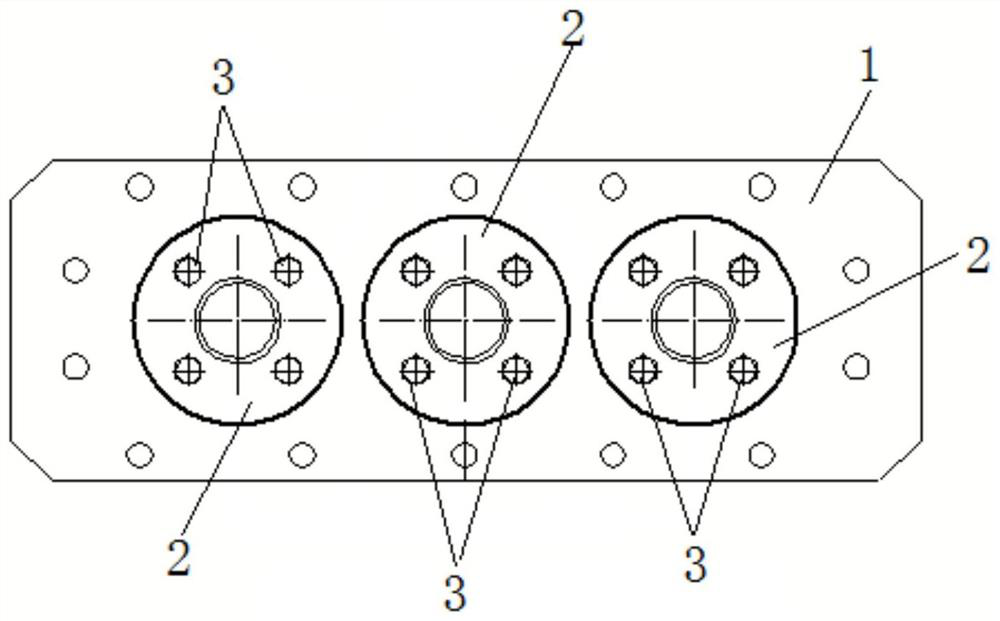

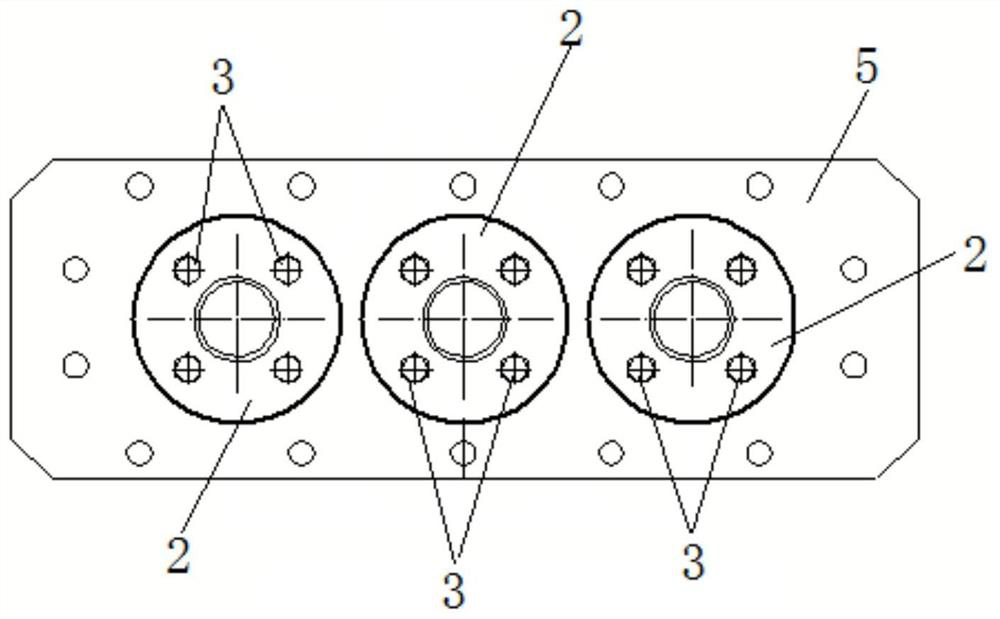

Method for prolonging service life of through-water cooler for bar rolling

PendingCN113182369AExtended service lifeAvoid scrappingWork cooling devicesMetal rolling arrangementsMechanical engineeringWater pipe

The invention discloses a method for prolonging the service life of a through-water cooler for bar rolling. A through-water pipe is connected with a water cooling seat of the through-water cooler through a flange bolt assembly, and the through-water pipe is connected with a water return seat of the through-water cooler through a flange bolt assembly. By adopting the method, the problem that a Venturi pipe in the through water cooler cannot be maintained due to single radial wear is solved.

Owner:HANZHONG STEEL LTDRP OF SHAANXI STEEL GRP

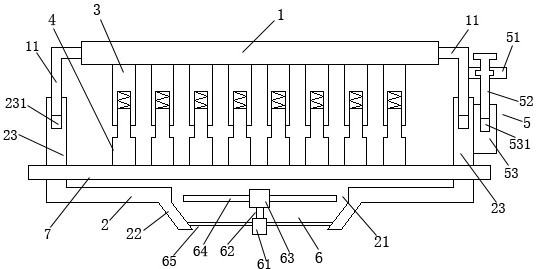

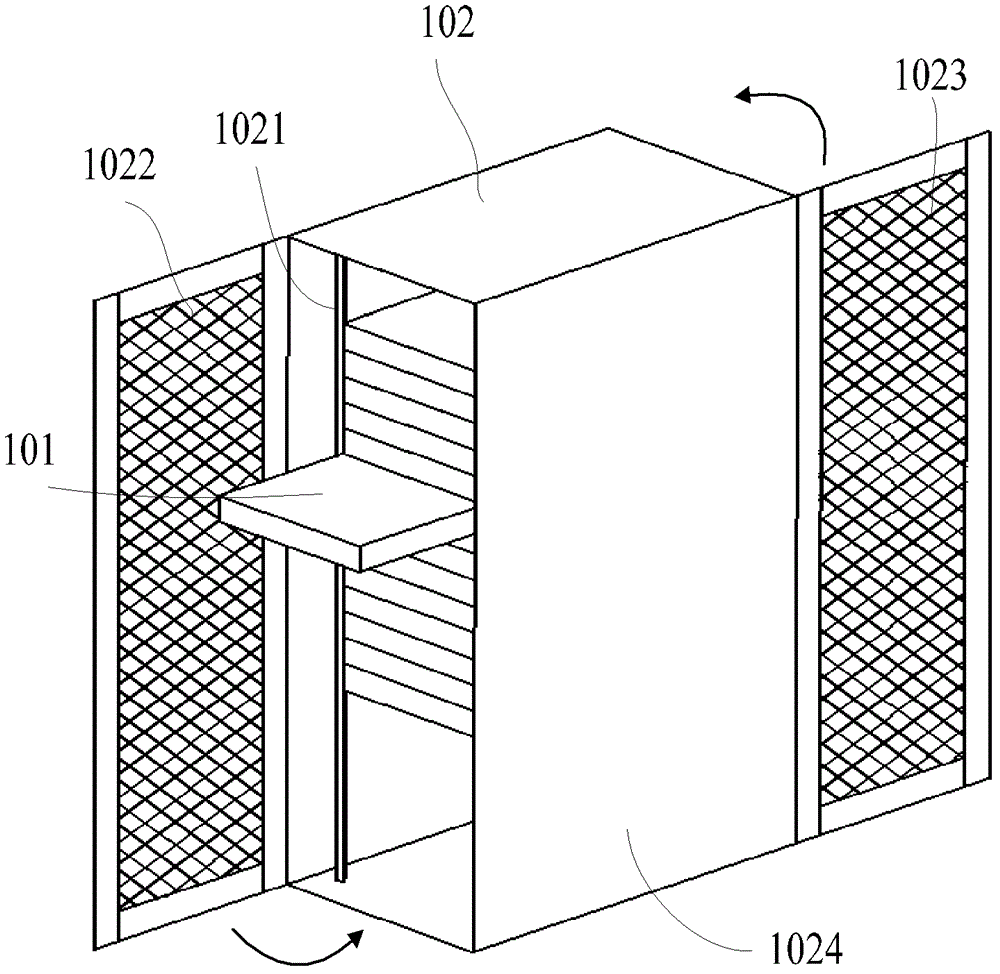

An electronic equipment cooling system with auxiliary cooling device

ActiveCN103037665BSolve the problem of not getting effective coolingSolve the problem of overheating caused by high temperatureCooling/ventilation/heating modificationsElectronic equipmentWaste management

Embodiments of the present invention disclose an electronic equipment cooling system including: a cabinet; at least one electronic equipment chassis that is installed inside the cabinet; and an auxiliary cooling device including an air pressurizing device, an air supply plenum box, and an air-guiding device. The air supply plenum box is disposed on an inner side of the cabinet. The air pressurizing device is disposed at the top or bottom of the cabinet, and an air exhaust on a sidewall of the air pressurizing device is connected to a corresponding air intake on a sidewall of the air supply plenum box. The air-guiding device is installed inside the electronic equipment chassis, an air intake of the air-guiding device is connected to an air exhaust of the air supply plenum device, and an air exhaust of the air-guiding device faces a component inside the electronic equipment chassis.

Owner:深圳市新凯来技术有限公司

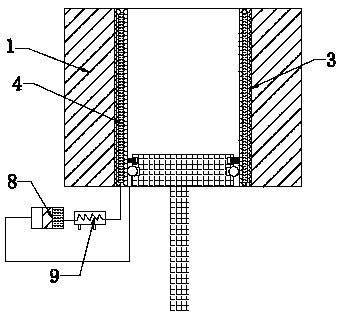

cooling engine block

ActiveCN106401791BDoes not affect cooling effectThe overall thickness is thinEngine componentsHot gas positive displacement engine plantsPiston ringCooling effect

The invention discloses a cylinder body structure of a heat engine, and particularly relates to an efficient cooling engine cylinder. The efficient cooling engine cylinder comprises a cylinder body with high-pressure working medium gas expansion inside, an inner cavity of the cylinder body is provided with a jacket embedded on the inner wall of the cylinder body, the jacket is provided with a fluid inner cavity, and a cooling flow way is formed in the fluid inner cavity and is connected with a high-pressure oil cooler and a pressurizing device. By the adoption of the structure, the jacket with a circular cooling channel is arranged in the inner cavity of the cylinder body, the circular cooling channel is sequentially in series connection with a high-pressure oil cooler and the pressurizing device or directly connected with the high-pressure oil cooler and the pressurizing device, and accordingly through introducing of high-pressure cooling oil into the circular cooling flow way, the oil pressure and the pressure of high-pressure working media in the inner cavity of the cylinder body are equivalent; thus, the thickness of the inner cylinder wall can be smaller, the temperature brought by wear between a piston ring and the inner cylinder wall can be absorbed, and according to the efficient cooling cylinder body of the heat engine, no matter how much the thickness of the cylinder body is increased, the cooling effect is not affected.

Owner:太仓市海丰金属制品有限公司

Forced circulation evaporation cooling device of hydro-generator stator busbar

ActiveCN102969838BAvoid short circuit accidentsImprove securityCooling/ventillation arrangementBusbarEvaporation

Provided is a forced circulation evaporation cooling device of a hydro-generator stator busbar. The stator busbar (12), a condenser (21), a liquid storage tank (30), a cooling device (32), a pump (1), a pressure stabilizing tank (2), a flowmeter (6), a liquid dividing pipe (8), a gas collecting pipe (16), a liquid supply main pipe (3), a gas outlet pipe (18), a liquid return main pipe (27), a total liquid return main pipe (37), a by-pass pipe (4) and an electro-liquid separation joint are connected to form an evaporative cooling circulation loop. An evaporative cooling medium in the loop is driven by a pump. The stator busbar includes one or a plurality of busbar branches, an inlet and an outlet of each busbar branch are respectively connected with the liquid dividing pipe and the gas collecting pipe through the electro-liquid separation joint and an insulation guide pipe, the busbar branches are connected in parallel, and the stator busbar is connected with the pump, the condenser, the cooling device and the like to form the independent evaporative cooling circulation loop. The forced circulation evaporation cooling device enables a plurality of busbars to be combined to form a unified parallel-connection pipeline and builds the independent evaporative cooling circulation loop.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com