Series type air cylinder cover water channel structure

A cylinder head, tandem technology, applied in the direction of cylinder head, cylinder, engine components, etc., can solve the problems of difficult installation, extra space occupation of internal combustion engine, increase processing and manufacturing cost, etc., to reduce the intensity of installation operation and save process plugs , the effect of reducing the number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

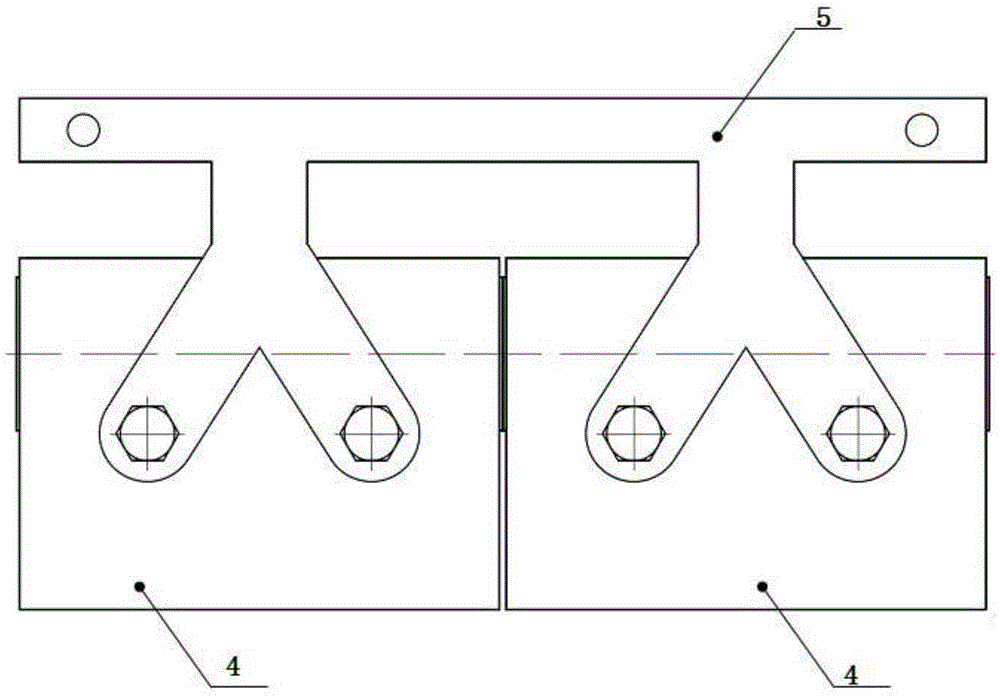

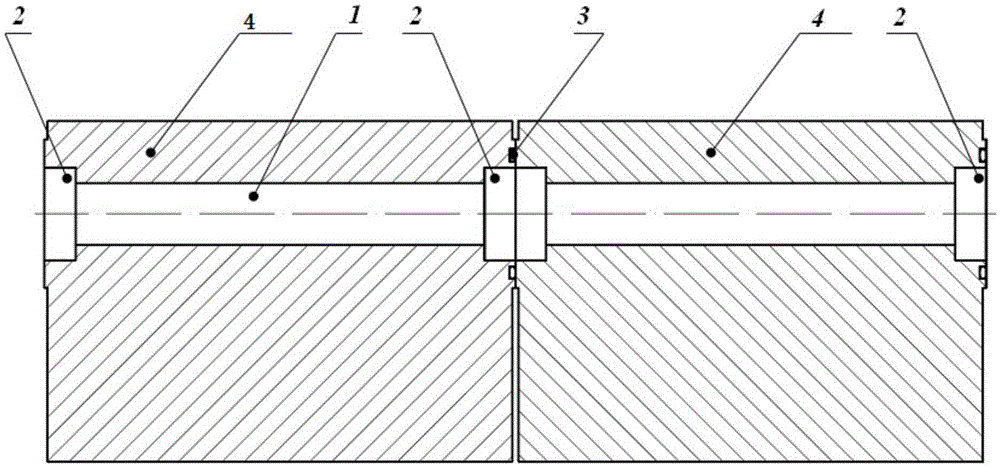

[0018] A tandem cylinder head waterway structure, such as figure 1 As shown, each cylinder head 4 is provided with a water channel 1 inside, which was designed when the cylinder head 4 was cast. The two ends of the water channel 1 are used to support the core. The position is provided with a series nozzle 2, and finally the series nozzle The outer edge position of 2 is processed to place the ring groove of O-shaped rubber sealing ring 3, and the O-shaped rubber sealing ring 3 is embedded in the ring groove; the water passages 1 of multiple cylinder heads 4 are connected through the serial nozzles 2 at both ends, and multiple When the cylinder heads 4 are assembled together, they form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com