An electronic equipment cooling system with auxiliary cooling device

An electronic equipment and auxiliary cooling technology, which is applied in the construction of electrical equipment components, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of overheating inlet temperature, insufficient cooling air volume, high inlet temperature, etc., and achieve the goal of solving overheating problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

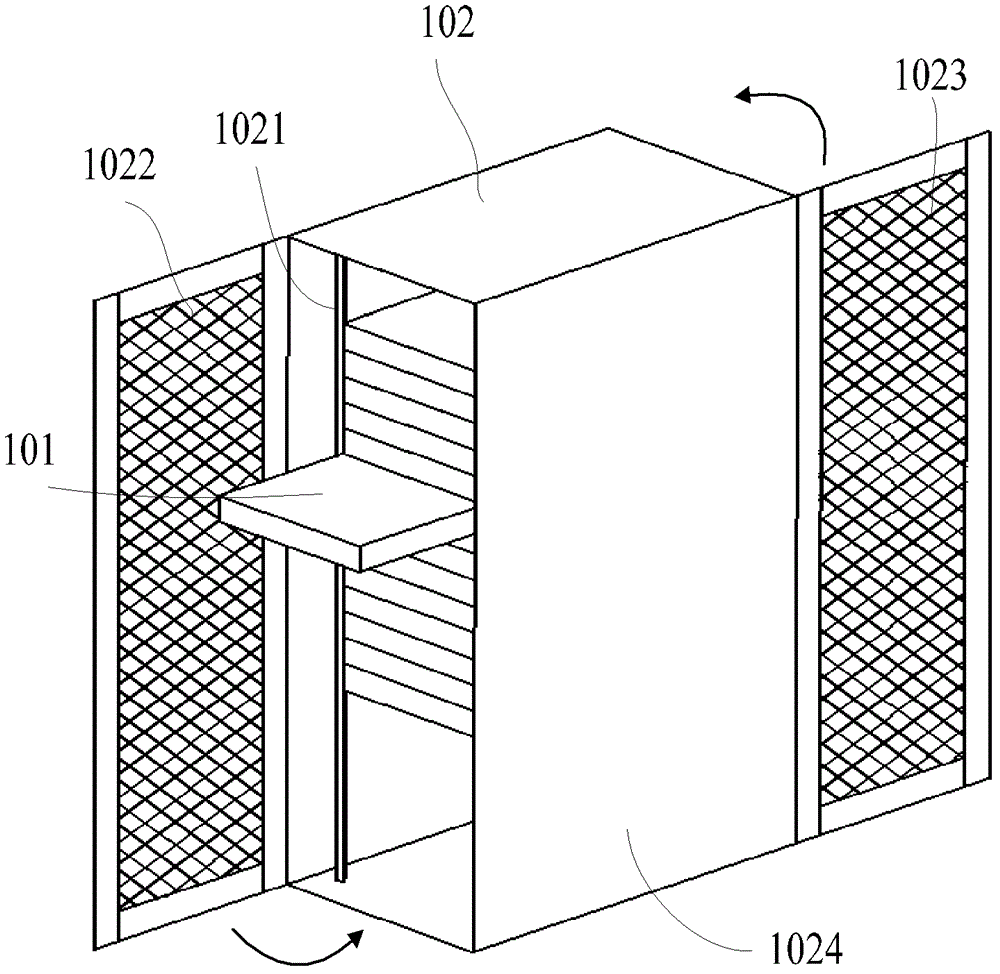

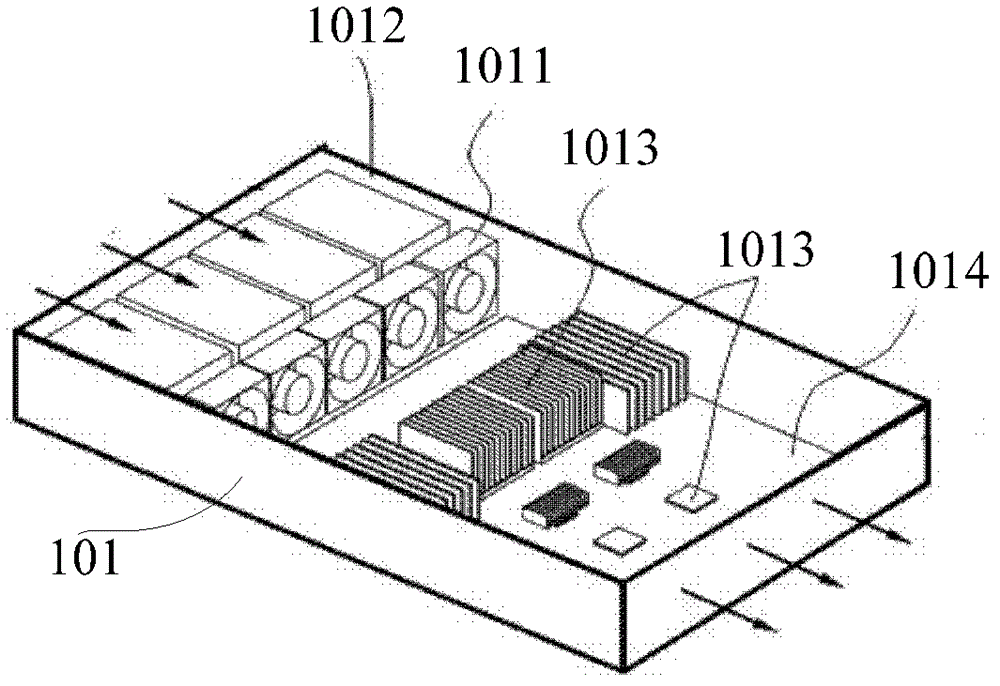

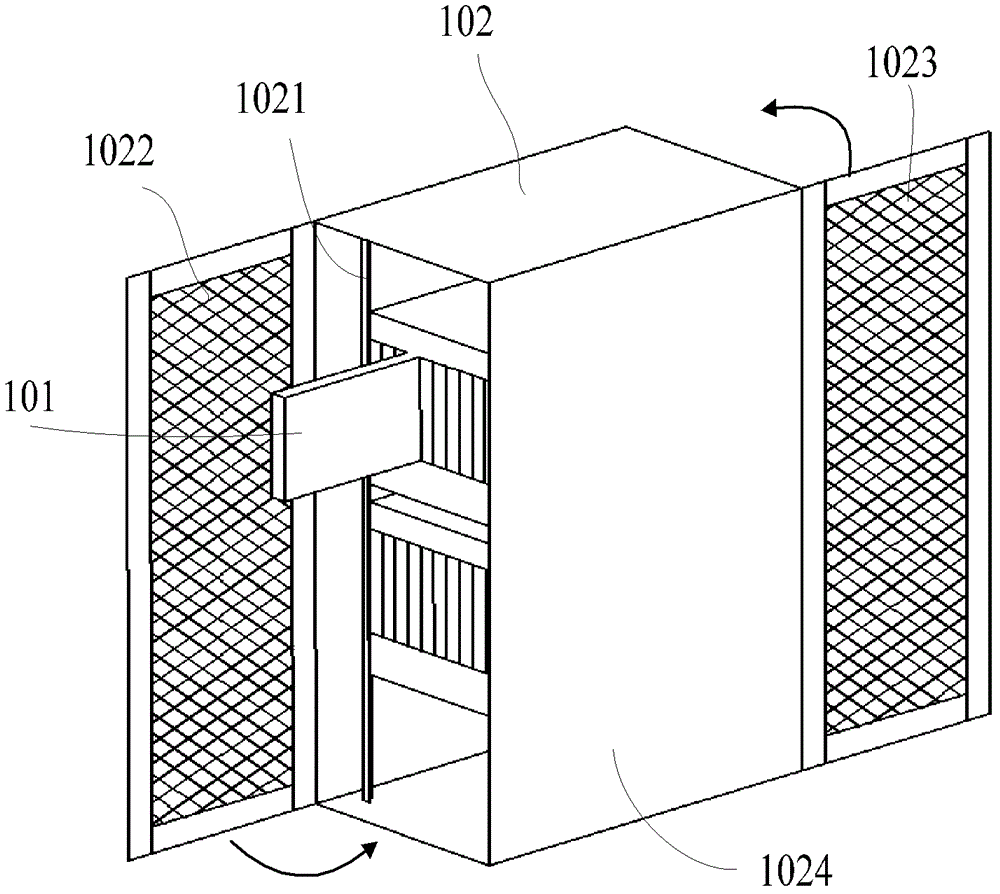

[0023] An embodiment of the present invention provides an electronic equipment cooling system with an auxiliary cooling device, which is used for the electronic equipment cooling system to use its own auxiliary cooling device to cool the devices with high heat generation in the electronic equipment chassis, so that the devices with large heat generation can Effective cooling is obtained without affecting the cooling effect of other devices, and at the same time, the inlet temperature of the devices in the electronic equipment chassis on the upper part of the cabinet can be maintained within an appropriate range to solve the problem of overheating.

[0024] In an embodiment of the present invention, an electronic equipment cooling system with an auxiliary cooling device includes at least one electronic equipment chassis, a cabinet for installing the electronic equipment chassis, and an auxiliary cooling device for dissipating heat from components in the electronic equipment chass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com