cooling engine block

An engine block and cylinder block technology, which is applied in engine components, machines/engines, hot gas variable capacity engine devices, etc., can solve problems such as inability to effectively reduce the temperature of the cylinder block, accelerate piston ring wear, and hinder development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

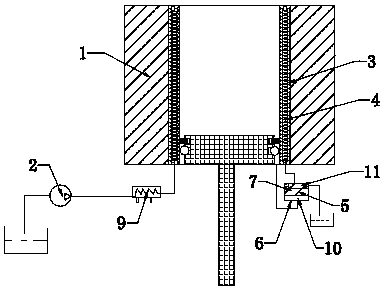

Embodiment 1

[0022] Such as figure 1 As shown, the cooling engine cylinder block of the present invention includes a cylinder block 1 in which a high-pressure working fluid gas is expanded. The inner cavity of the cylinder block 1 has a jacket 3 embedded on the inner wall of the cylinder, and the jacket 3 has a fluid inner cavity. , The fluid cavity forms a cooling channel 4, which connects the high-pressure oil cooler 9 and the supercharger, and the cooling channel 4 is connected in series with the high-pressure oil cooler 9 and the supercharger. The supercharger is one Oil pump 2, cooling channel 4 is provided with an oil outlet, cooling channel 4 is equipped with an overflow valve 5 at the oil outlet, so that the coolant cooled by the cooler flows through the cooling channel 4 to cool the cylinder block Return to the oil tank through the overflow valve. The overflow valve is a gas-liquid balanced overflow valve. The gas-liquid balanced overflow valve includes a valve body 6 in which a col...

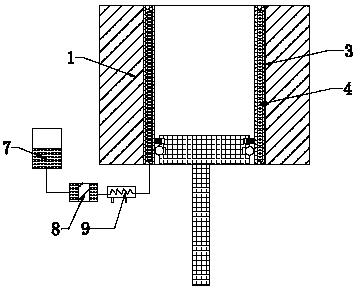

Embodiment 2

[0024] Such as figure 2 As shown, the cooling engine cylinder block of the present invention includes a cylinder block 1 in which a high-pressure working fluid gas is expanded. The inner cavity of the cylinder block 1 has a jacket 3 embedded on the inner wall of the cylinder, and the jacket 3 has a fluid inner cavity. , The fluid cavity forms a cooling channel 4, which connects the high-pressure oil cooler 9 and the supercharger, and the cooling channel 4 is connected in series with the high-pressure oil cooler 9 and the supercharger. The supercharger is one The external accumulator 7, the high-pressure working fluid gas stored in the accumulator 7, the accumulator 7 applies a balanced pressure to the coolant in the cooling channel 4, and the high-pressure oil cooler 9 and the accumulator 7 are arranged between There is a balancing piston 8. The high-pressure working medium in the cylinder 1 pushes the balancing piston 8 to apply a balanced pressure to the coolant in the coolin...

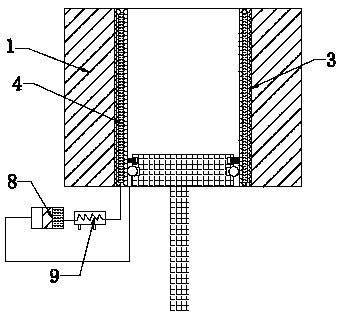

Embodiment 3

[0026] Such as image 3 As shown, the cooling engine cylinder block of the present invention includes a cylinder block 1 in which a high-pressure working fluid gas is expanded. The inner cavity of the cylinder block 1 has a jacket 3 embedded on the inner wall of the cylinder, and the jacket 3 has a fluid inner cavity. , The fluid cavity forms a cooling channel 4, the cooling channel 4 is connected to the high-pressure oil cooler 9 and the supercharger, the cooling channel 4 is connected in series with the high-pressure oil cooler 9 and the supercharger, and the cooling channel 4 is connected in series with the high pressure The oil cooler 9 and the supercharger. The supercharger is the inner cavity of the cylinder block 1. The high-pressure working medium gas in the inner cavity of the cylinder block 1 applies a pressure to the coolant in the cooling channel 4 to balance The pressure difference between the cooling channel 4 and the inner cavity of the cylinder block 1. A balance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com