Method for prolonging service life of through-water cooler for bar rolling

A technology for piercing water coolers and rods, which is applied in metal rolling, metal rolling, and workpiece cooling devices, etc. It can solve the problem that the Venturi tube in the water piercing cooler cannot be maintained, so as to improve the service life and avoid the overall Effect of replacement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

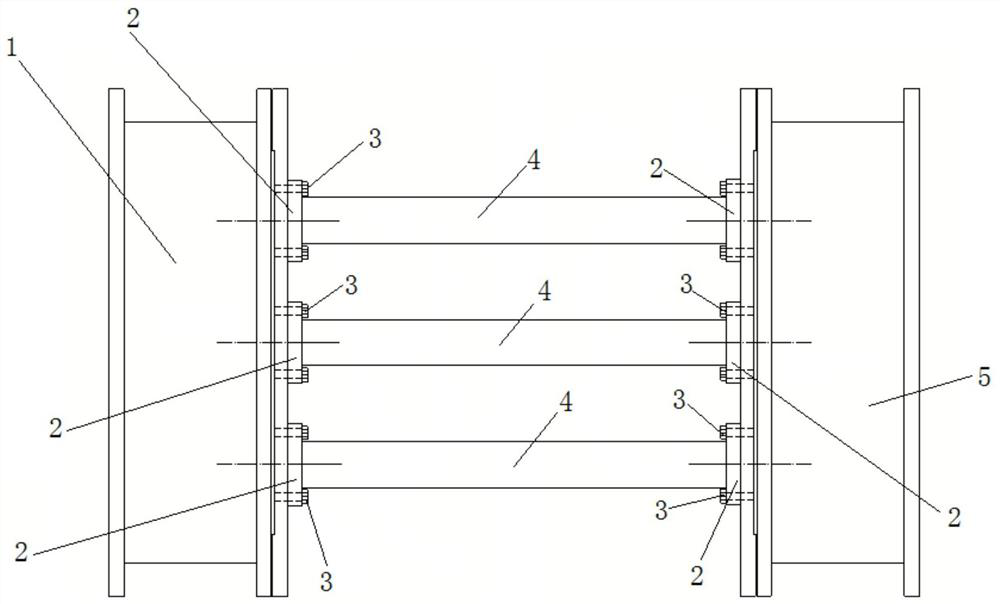

[0019] figure 1 It is a schematic diagram of a water-piercing cooler for three-slit rolling after flange connection is adopted; the three water-piercing pipes 4 are respectively connected to the water-cooling seat 1 of the water-piercing cooler and the return water seat 5 of the water-piercing cooler.

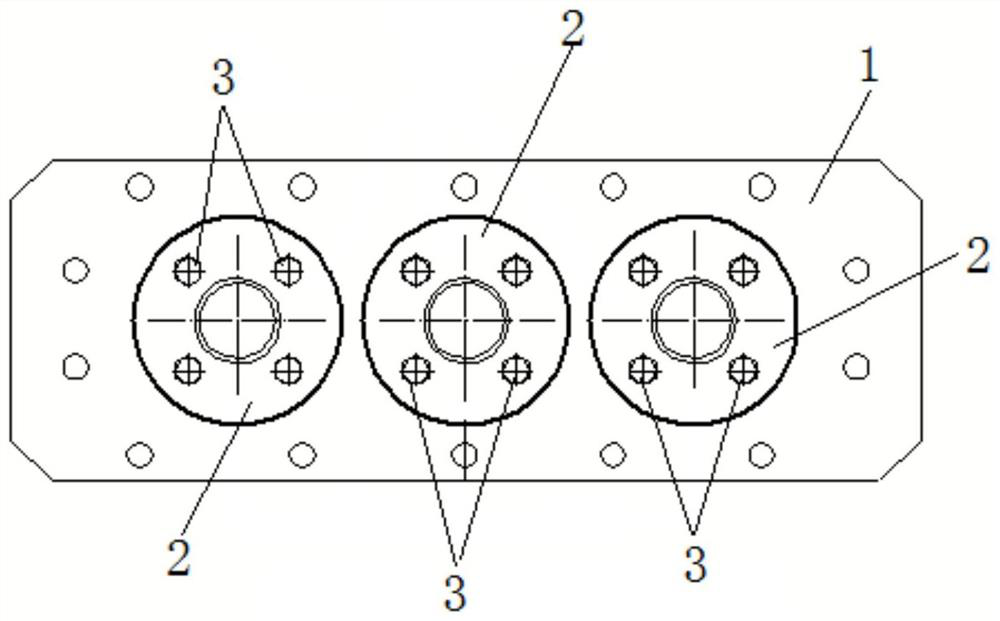

[0020] Such as figure 2 As shown, when the water-piercing pipe 4 is connected to the water-cooling seat 1 of the water-piercing cooler, there are four bolt holes on the flange 2 (or eight, set according to the actual situation), and the bolt holes match the number of bolts 3 .

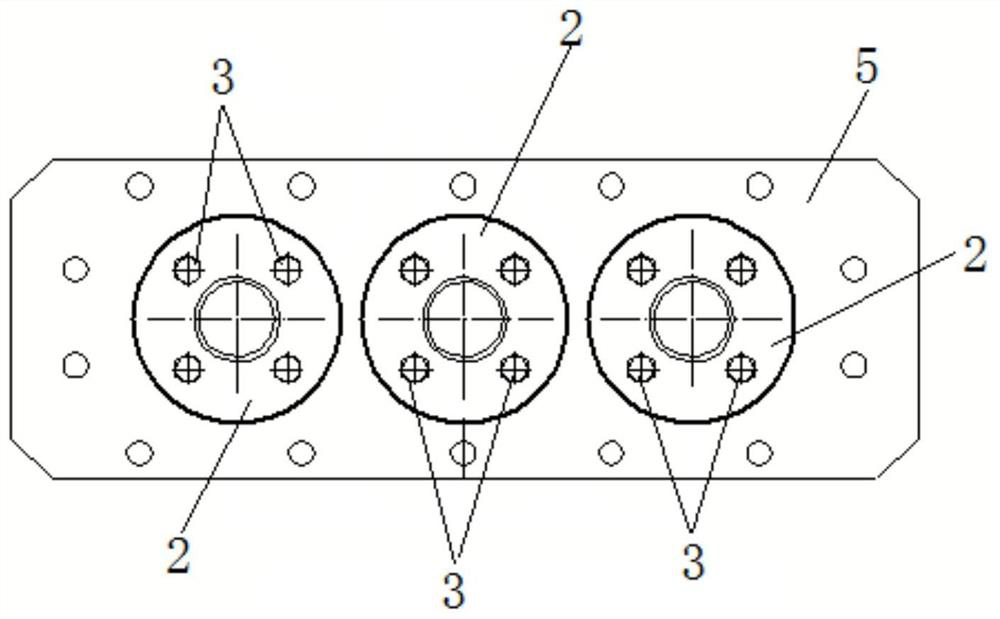

[0021] Such as image 3 As shown, when the water-piercing pipe 4 is connected with the return seat 5 of the water-piercing cooler, there are four bolt holes on the flange 2 (or eight, set according to the actual situation); the number of the bolt holes and the bolt 3 match.

[0022] This embodiment 1 is a water-through cooler for three-slit rolling after adopting flange connection. , the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com