Temperature and pressing measuring device on water-cooling wall surface of combustion chamber and machining method thereof

A technology of water-cooled wall surface and pressure measuring device, applied in the direction of measuring device, instrument, etc., can solve the problems of temperature value, pressure value, leakage of cooling medium, increase of flow resistance of cooling channel, etc., and achieve the effect of reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

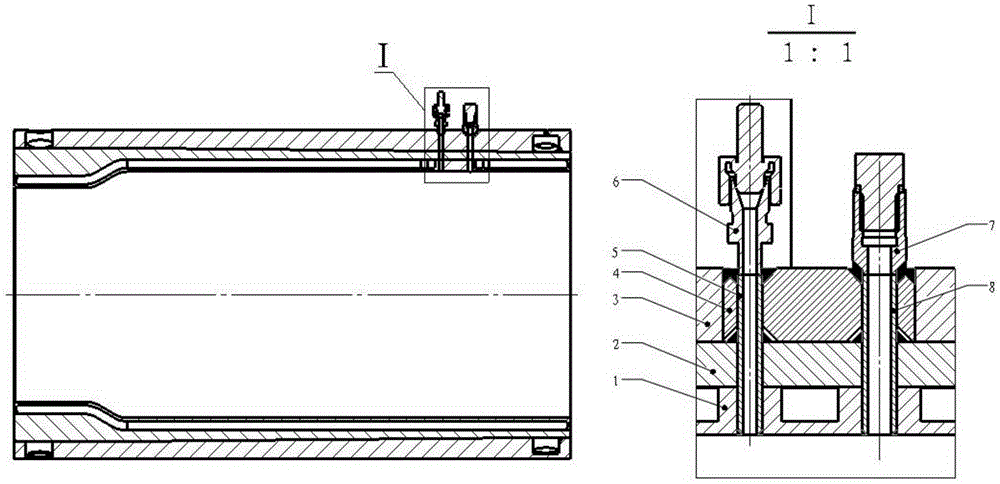

[0031] A method for processing a temperature and pressure measurement device on a water-cooled wall surface of a combustion chamber, comprising the following steps:

[0032] In the first step, the outer surface of the combustion inner wall 1 is finished, and the roughness of the outer surface of the combustion inner wall 1 is 6.3.

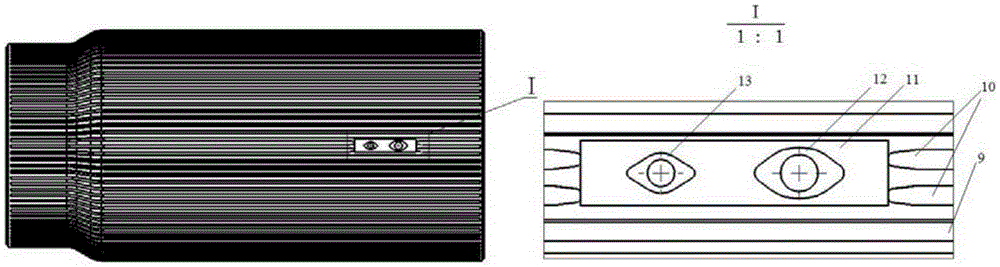

[0033] The second step is to process the water channel 9 on the outer surface of the combustion chamber wall 1 with a numerical control milling machine. The depth of the water channel 9 is 11 mm and the width is 4 mm; The two reinforcing ribs 11 process the effusion chamber 10, the effusion chamber 10 has a width of 20 mm and a length of 75 mm; and in the effusion chamber 10, a fish-eye type temperature measurement area 12, a fish-eye type pressure measurement area 13, and a fish-eye type pressure measurement area 13 are processed. Type temperature measuring area 12 is 15mm wide and 25mm long, and fisheye type pressure measuring area 13 is 11mm wid...

Embodiment 2

[0041] A method for processing a temperature and pressure measurement device on a water-cooled wall surface of a combustion chamber, comprising the following steps:

[0042] In the first step, the outer surface of the inner wall of the combustion chamber is finished, and the roughness of the outer surface of the inner wall of the combustion chamber is 3.2.

[0043]The second step is to process the water passage on the outer surface of the inner wall of the combustion chamber with a CNC milling machine. The depth of the water passage is 13mm and the width is 8mm; Outlet effusion cavity The effusion cavity is 40mm wide and 90mm long, and a fish-eye temperature measurement area and a fish-eye pressure measurement area are processed in the effusion cavity. The fish-eye temperature measurement area is 18mm wide and 30mm long, and the fish-eye type The pressure measuring area is 15mm wide and 25mm long.

[0044] The third step is to process two temperature measuring holes equal to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com