Combined cavity blow molding die

A technology of blow mold and combined cavity, which is applied in household appliances, other household appliances, household components, etc. It can solve problems affecting production efficiency and product quality, heat dissipation design, cavity cooling efficiency inconsistency, etc., to improve production Efficiency and product quality, improved consistency, and improved production flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

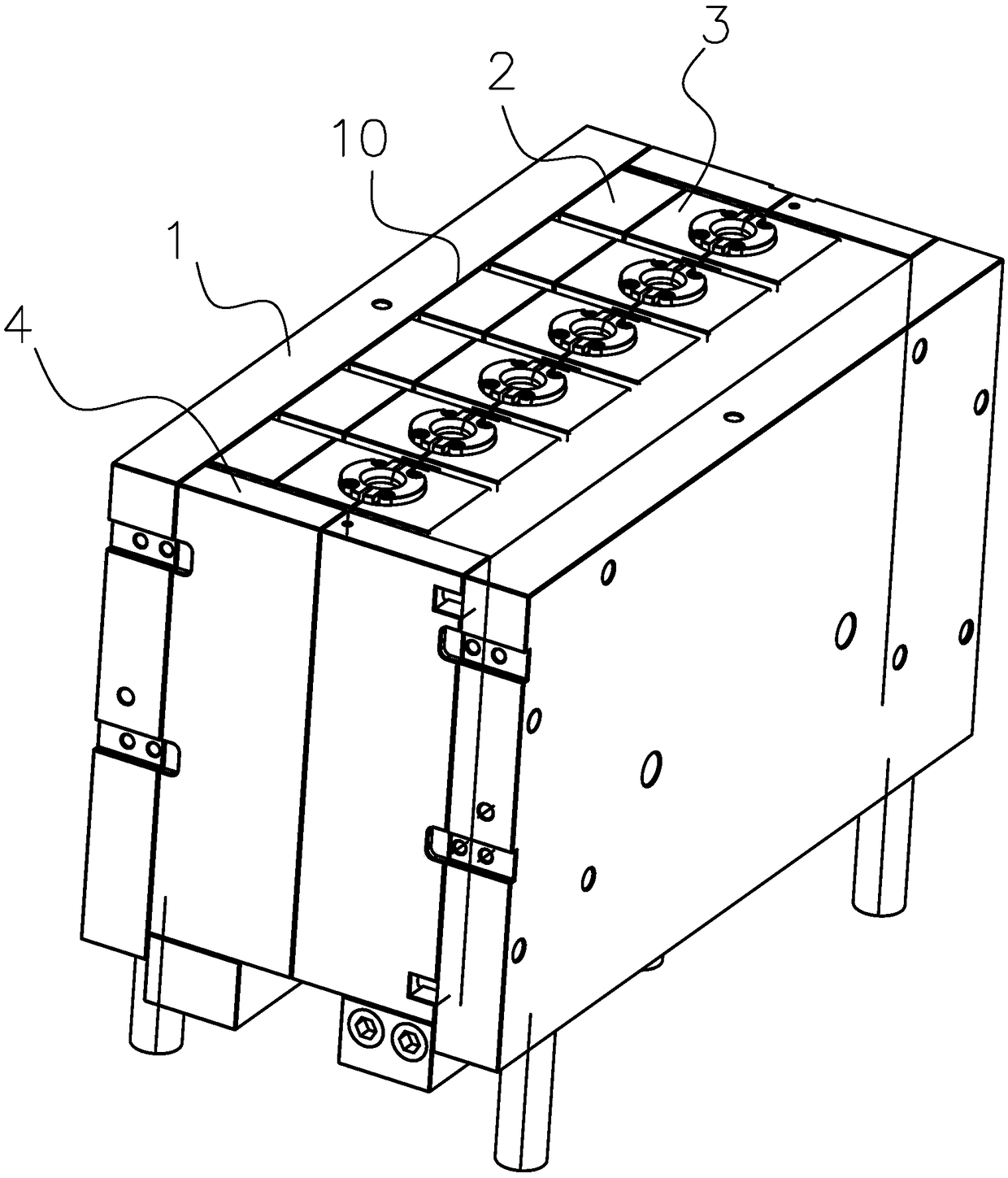

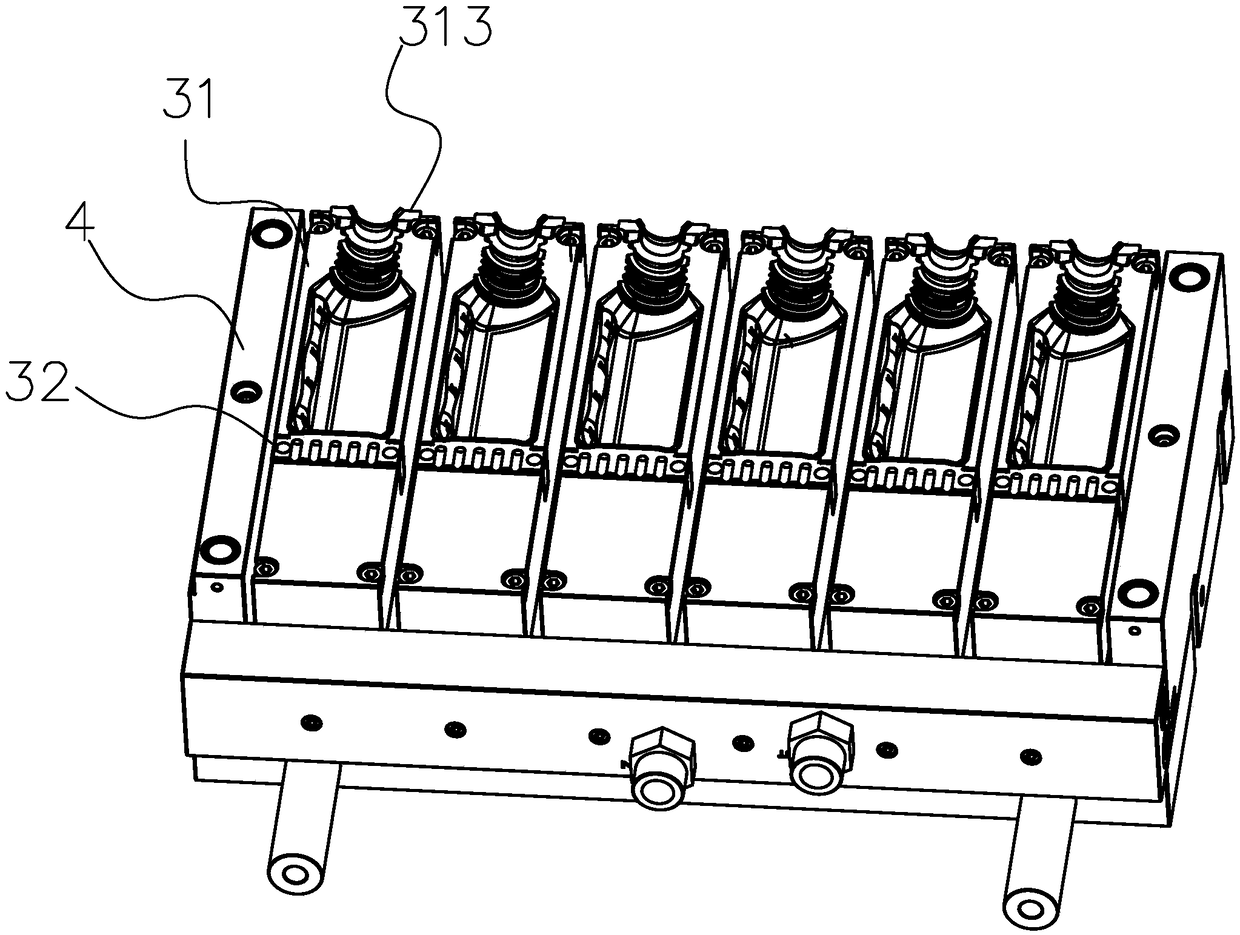

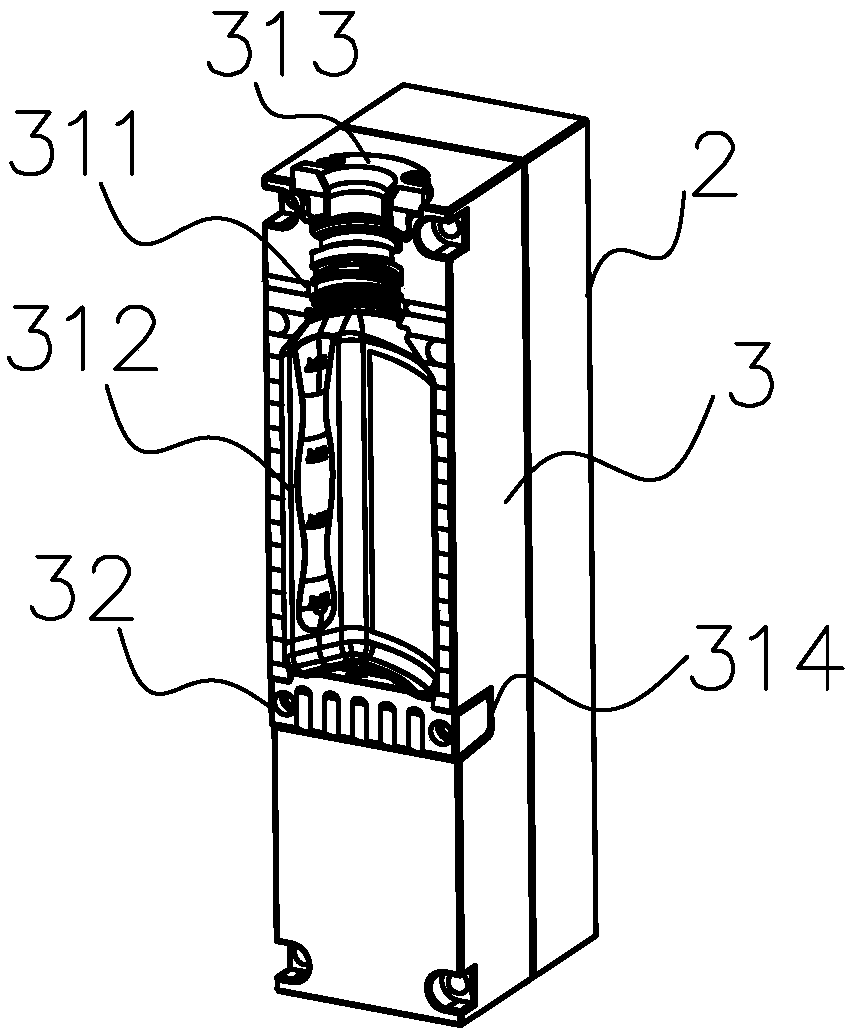

[0022] Such as figure 1 , figure 2 , image 3 and Figure 4 A combined cavity blow mold is shown, comprising: mutually independent cavity modules 3, mutually independent cooling modules 2, and a mold bottom plate 1; the cooling module 2 is installed on the mold bottom plate 1, and the The cavity module 3 is installed on the cooling module 2, and the cavity module 3, the cooling module 2, and the mold bottom plate 1 are all arranged in pairs. Due to the independent cavity module design, different numbers of cavity modules or even different types of cavity modules can be set according to production needs, which makes production more flexible, and the independent cooling modules reduce the number of cavity modules Does not affect cooling effect.

[0023] The cavity module 3 described in the present invention is a spliced module including a bottle body cavity blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com