Fluid supply system and method of operating a fluid supply system

A technology of fluid supply and mass flow, which is applied in transportation and packaging, components with teeth, thin material processing, etc. It can solve the problems of fluid system loss and other problems, and achieve the effect of reducing flow loss and reducing pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

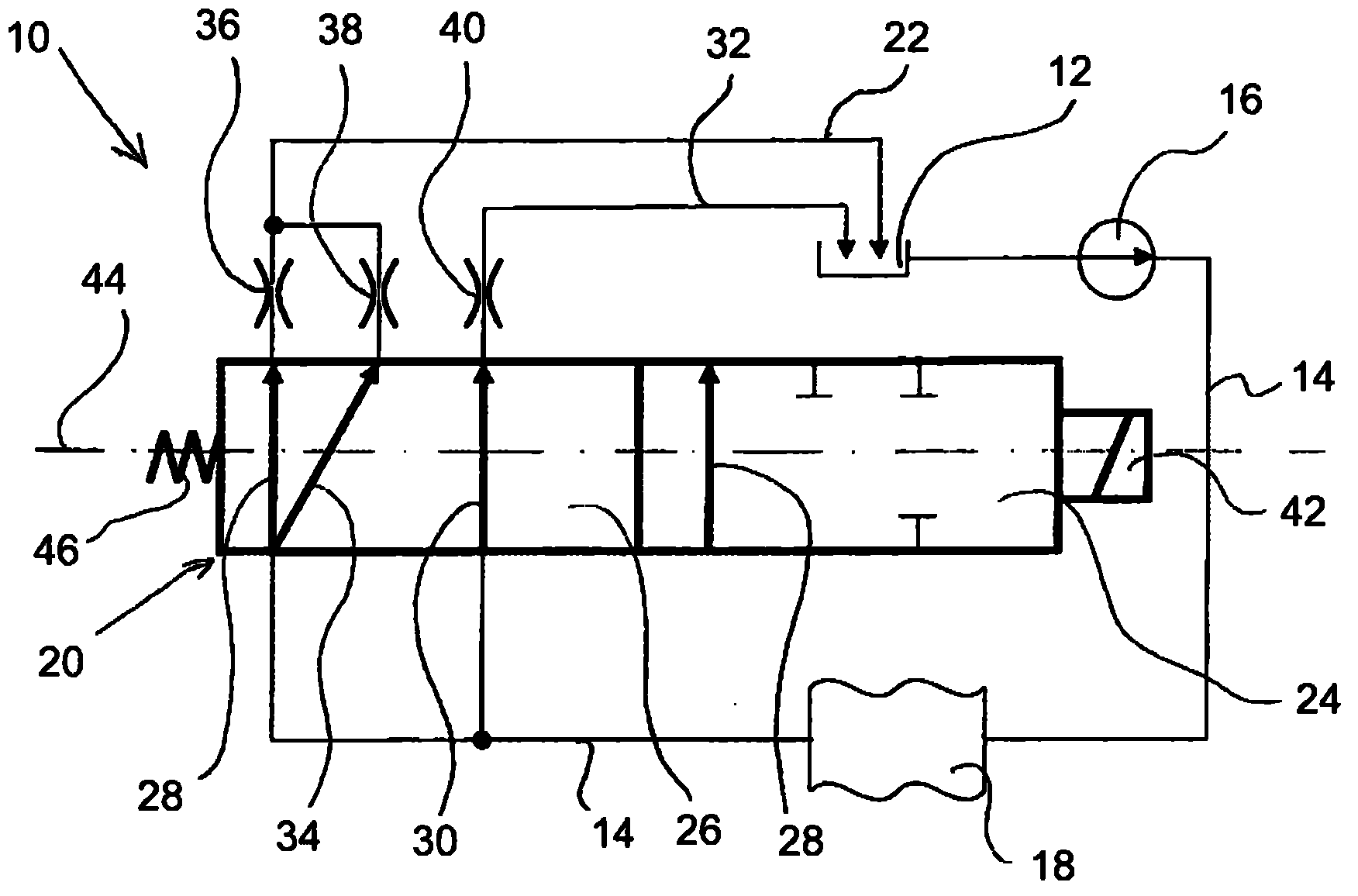

[0023] figure 1 The fluid supply system 10 shown in includes an oil sump 12 through which a transmission oil mass flow Feed to the cooling channel 14. The cooling channel 14 includes a radiator 18 which cools the transmission oil, in particular after it has cooled the automatic transmission, not shown. The cooling channel 15 is connected via a displacement valve 20 to the mass flow Lubricating oil channel 22, said lubricating oil channel terminates at oil groove 12.

[0024] The shift valve includes a figure 1 The first chamber 24 on the right side of the middle displacement valve 20, and is arranged in figure 1 The second chamber on the left side of the shift valve 20. Via the first chamber 24 a first valve state can be set, with which the cooling channel 14 is connected to the lubricating oil channel 22 via a first valve path 28 without any branching. In the first valve state, the cooling mass flow corresponds to the lubrication mass flow

[0025] When the shift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com