A New Type of Durable Magnetized Anchor Rod

A bolt and durable technology, applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of bolt support strength reduction, back buckle pre-tightening force, bolt failure, etc., to avoid bolt fatigue Effects of damage and corrosion, relaxation of load transfer, and enhancement of bolt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

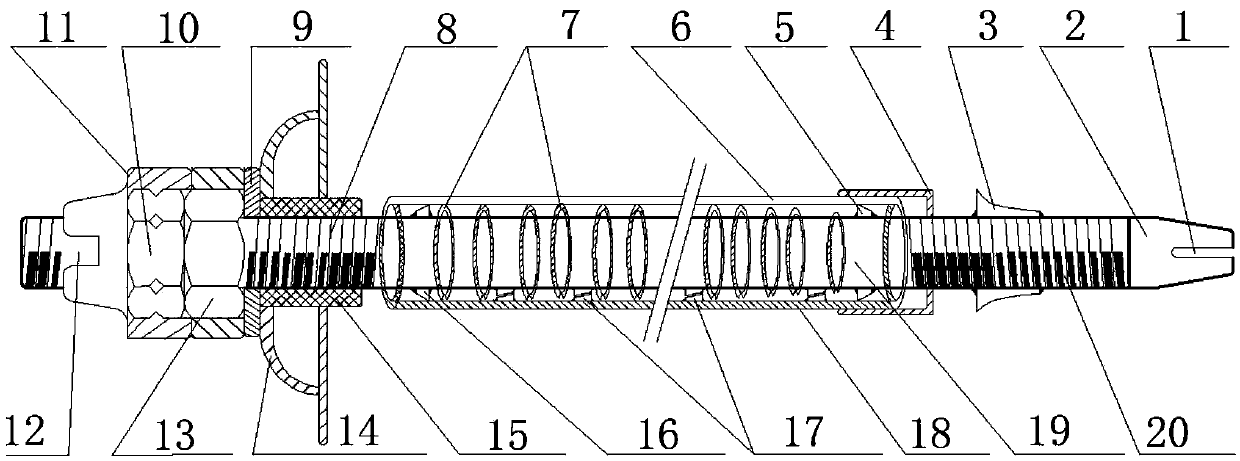

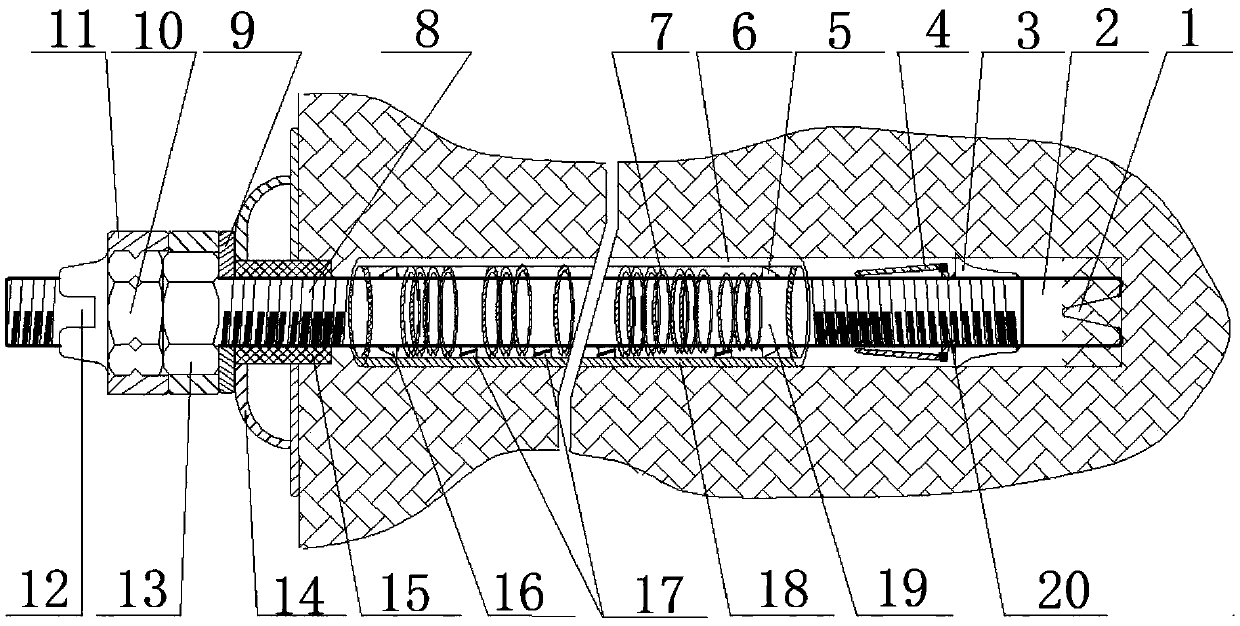

[0035] The present invention will be further described below in conjunction with accompanying drawing:

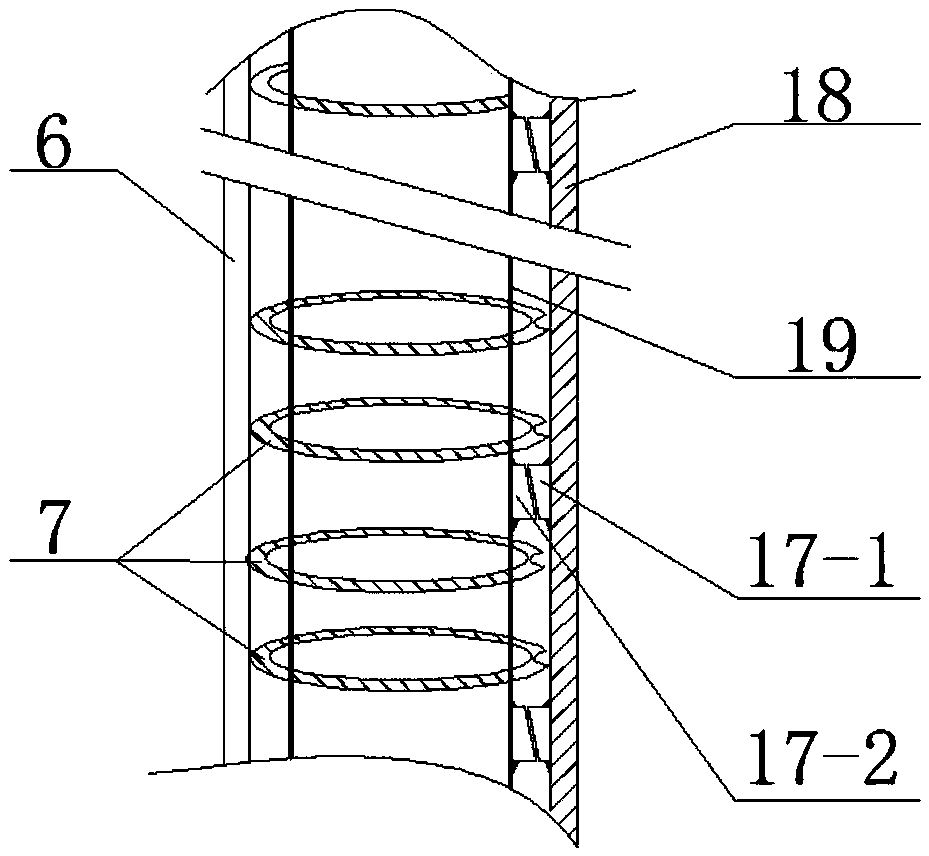

[0036] Working principle: The tapered end sleeve 2 with a symmetrical gap is used as a guiding element to drill the anchor rod body into the borehole. When the wide end of the tapered stop nut 3 is embedded in the surrounding rock deep in the borehole, the The threaded section 20 at the front end of the rod body constitutes a helical pair, which converts the rotary motion of the anchor rod body 19 into the axial propulsion movement of the borehole, thereby driving the claw-shaped elastic anti-expansion outer bushing 4 together with the threaded section 20 at the front end of the anchor rod body to the deep part of the borehole Pushing forward, the symmetrically distributed elastic claws 4-1 disengage and release the elastic magnetized slotted steel pipe 18. At the same time, the elastic claws 4-1 shrink radially and tightly fit the threaded section 20 at the front end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com