Water-cooling and air-cooling electronic power heat dissipation device

A technology of electronic power and heat dissipation devices, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve problems such as single, burnt out, and affect the stable operation of electronic equipment, so as to avoid wear gaps and ensure The effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

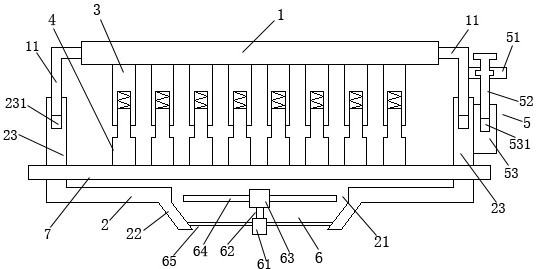

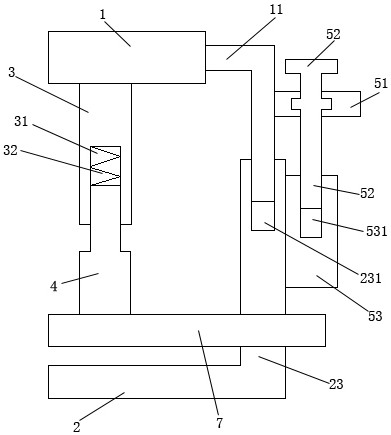

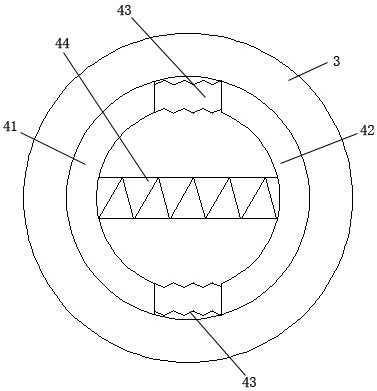

[0020] Such as Figures 1 to 3 As shown, a water-cooled air-cooled electronic power heat dissipation device includes a heat dissipation plate 1, a positioning heat dissipation fin 3, a floating heat dissipation fin 4, a telescopic drive mechanism 5, an abutting cooling water plate 7, a lower connecting plate 2, and an exhaust mechanism 6. The lower connection plate 2 is installed relatively parallel directly under the heat dissipation plate 1; the lower connection plate 2 is installed directly below the heat dissipation plate 1 floating up and down; the telescopic drive mechanism 5 is installed on the heat dissipation plate 1 and the lower connection One side of the plate 2; the telescopic drive mechanism 5 drives the lower connecting plate 2 to move up and down; the lower end surface of the heat dissipation plate 1 is uniformly and vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com