Forced air cooling chassis resisting marine atmospheric environment

A marine atmosphere, air-cooled machine technology, applied in electrical components, electrical equipment structural parts, cooling/ventilation/heating transformation and other directions, can solve the problems of dust accumulation, corrosion, affecting the cooling effect of equipment, etc., to reduce the difficulty of work , to avoid the effect of dust accumulation and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

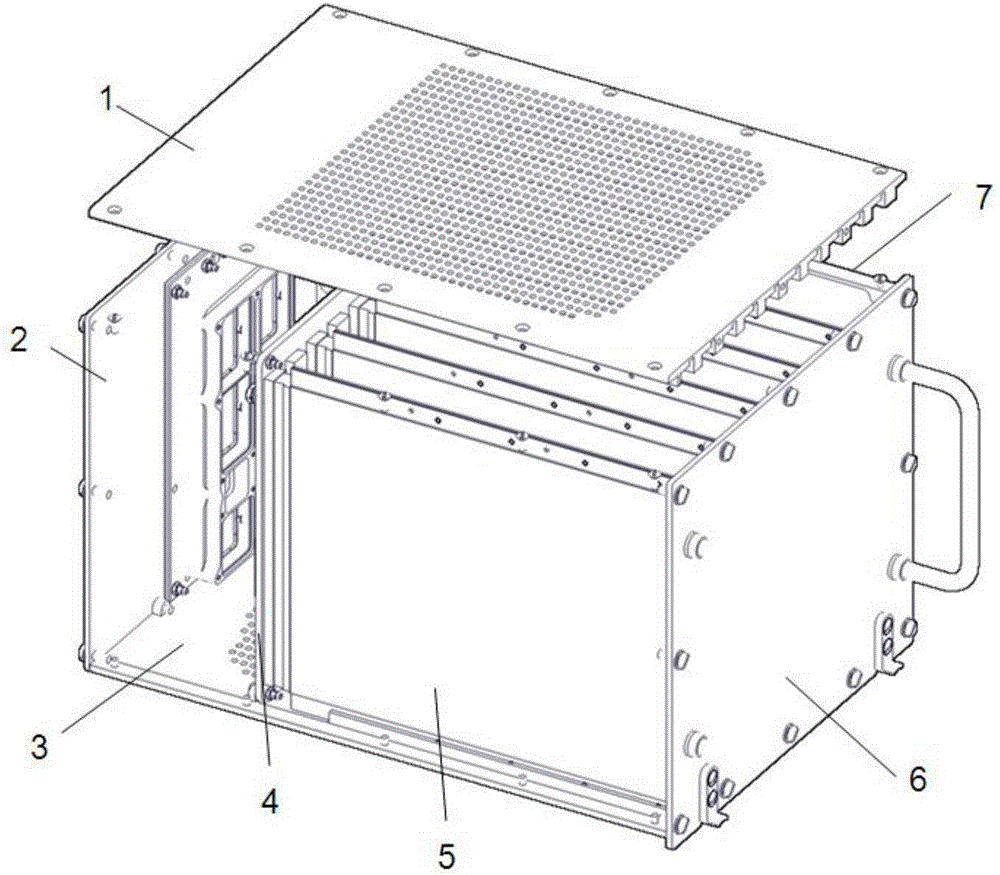

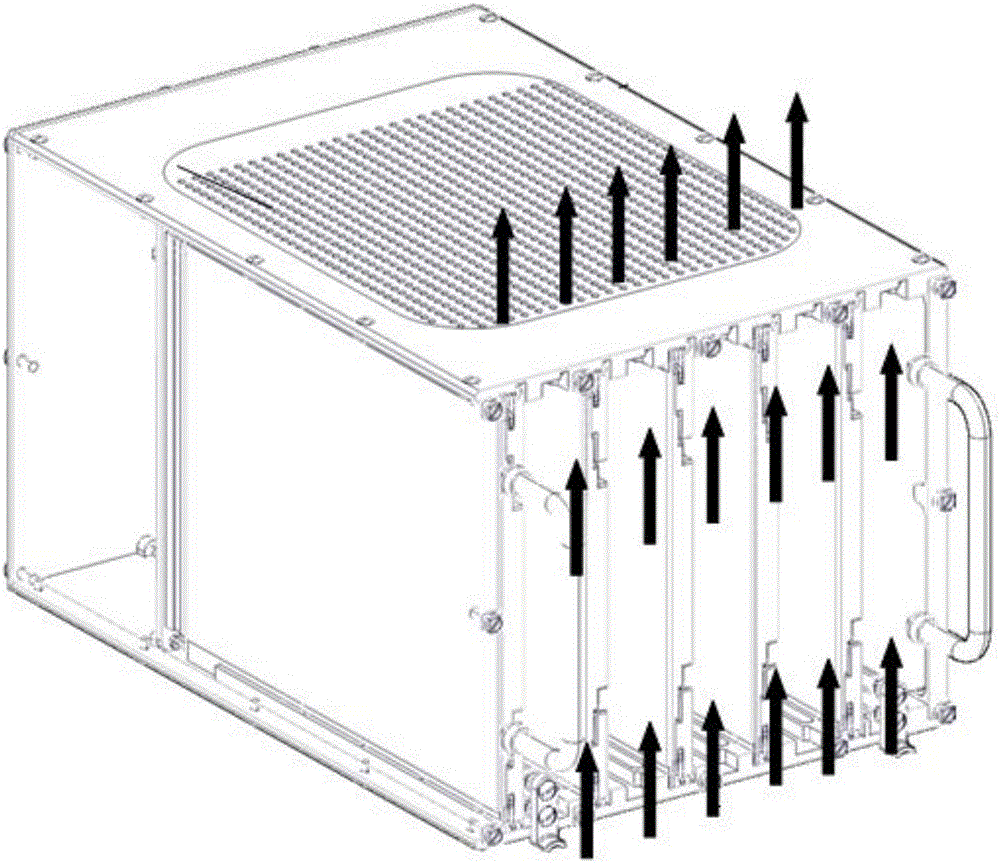

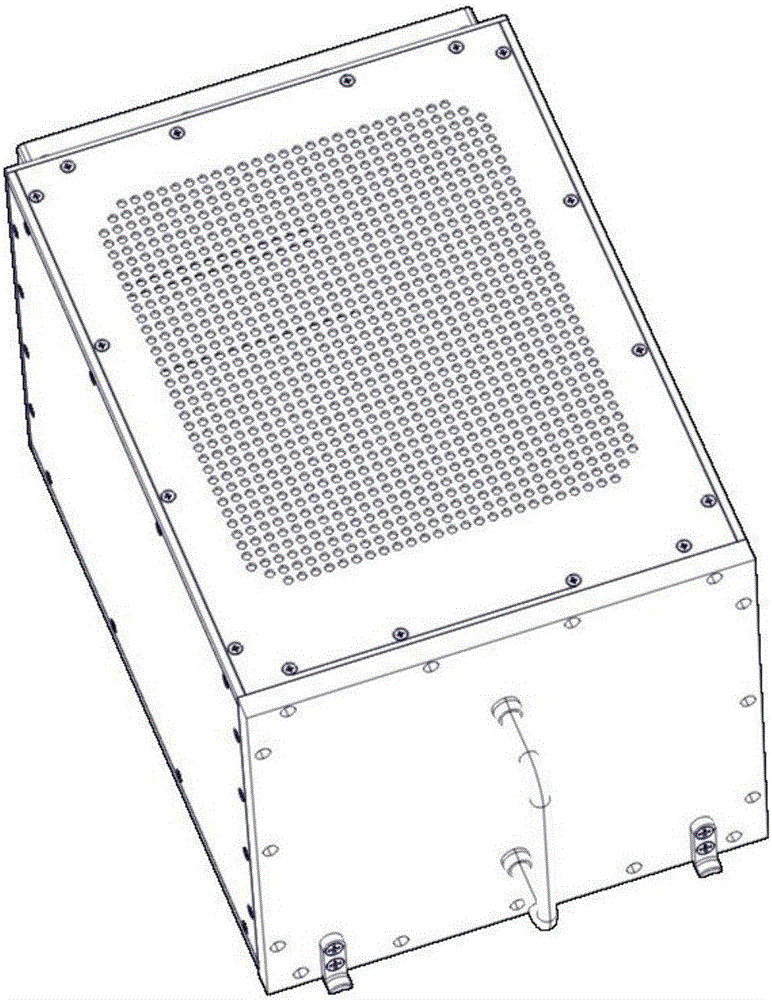

[0020] Such as Figure 3-5 As shown, a forced air-cooled chassis resistant to marine atmospheric environment includes an upper cover plate 1, a rear panel 2, a lower cover plate 3, a front panel 6, a right side plate 7 and a left side plate 8, and the upper cover plate 1 And the lower cover plate 3 has cooling holes for cooling air to enter and exit, it is characterized in that: the forced air cooling cabinet also includes a left cold plate 9, a right cold plate 10, a top plate 11 and a bottom plate 12, by the front panel 6, the rear panel 2. The left cold plate 9, the right cold plate 10, the top plate 11 and the bottom plate 12 constitute the main body of the case with a closed structure, and the upper cover plate 1, the lower cover plate 3, the right side plate 7 and the left side plate 8 cover the outside of the main body of the case , and the left cold plate 9 and the right cold plate 10 have cooling air passages communicating with the upper cover plate 1 and the lower co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com