Method for confirming damage of cooling water pipe of blast furnace cooling wall

A technology of cooling water pipes and staves, which is applied in the direction of measuring the rate of increase and deceleration of the fluid, using liquid/vacuum degree to measure the liquid tightness, etc., which can solve the problems of reducing cooling intensity, safety hazards, and damage to cooling water pipes, and achieve reduction Potential safety hazards, reduce labor intensity, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention is further described below:

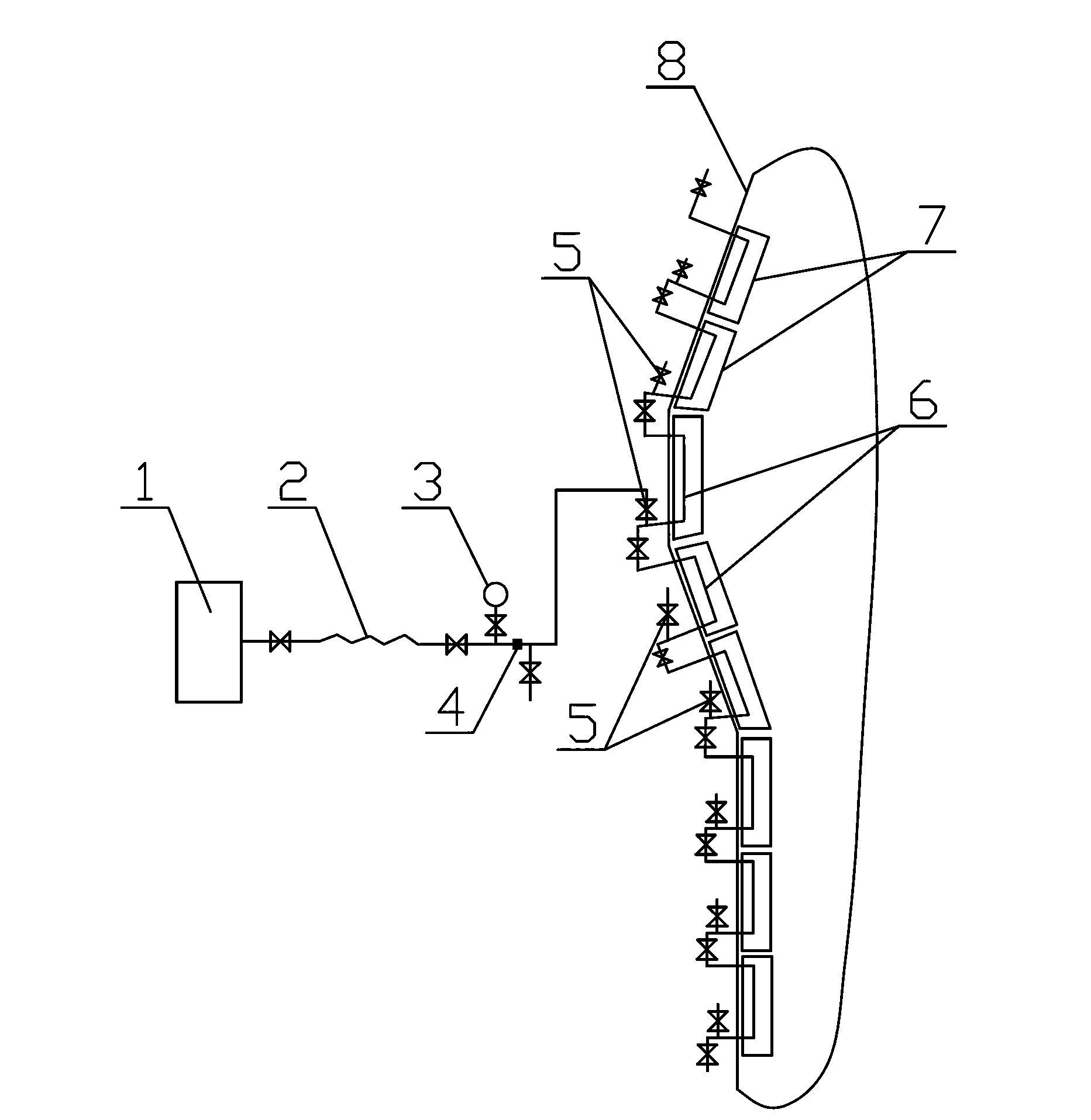

[0023] The invention discloses a method for confirming the damage of the cooling water pipe of the cooling wall of the blast furnace. Firstly, one wind belt 2 is prepared before the blast furnace is closed. , one side of the tee is provided with a pressure gauge 3, and the other side is provided with a joint 4, and then after the blast furnace is shut down, when there is no gas in the furnace body, each section of the cooling water pipe 6 that needs to be suppressed is exported, and the water discharge valve 5 of the cooling water pipe 6 is used , Connect the wind belt 2 to the water discharge valve 5 of the cooling water pipe 6, and press it step by step, first confirm that the water discharge valve 5 at both ends of the cooling water pipe 6 is closed, then open the water discharge valve 5 and connect it to the joint 4 of the tee, and close the water discharge Valve 5, and then open the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com