Mold release structure for four-angle core drawing of side face of air outlet shell

An air outlet and housing technology, which is applied in the field of the release structure of the four-angle core pulling on the side of the air outlet housing, can solve the problems of difficulty in designing the side of the air outlet housing, and achieves reduction in quantity, simplification of the assembly process, and reduction in manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

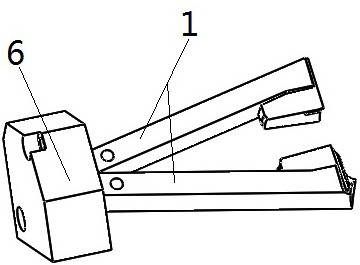

[0036] combined with Figure 1-11 , a demoulding structure with four-angle core-pulling on the side of the air outlet housing in this embodiment, including a first slider seat 301, a second slider seat 310, a third slider seat 311, and a fourth slider seat 312 , the first slider insert 1, the second slider insert 2 and the third slider insert 3, the first slider seat 301 is slidably connected to the second slider seat 310 at one end, the second slider The other end of the seat 310 is fixedly connected with the fourth slider seat 312, the third slider seat 311 is located between the second slider seat 310 and the fourth slider seat 312, and the first slider insert 1 is fixed on On the third slider seat 311, the second slider insert 2 and the third slider insert 3 are fixed on the first slider seat 301, and the second slider insert 2 passes through the second Slider seat 310, the third slider seat 311 and the fourth slider seat 312, the third slider insert 3 passes through the ...

Embodiment 2

[0039] combined with Figure 9 and 11 , a demoulding structure with four-angle core-pulling on the side of the air outlet shell in this embodiment, compared with the technical solution of Embodiment 1, the relative sliding side of the first slider seat 301 and the second slider seat 310 A fifth slider insert 5 is provided, and the second slider seat 310 is provided with a groove 51 opposite to the fifth slider insert 5, and the groove width of the groove 51 is greater than the width of the fifth slider insert 5 .

[0040] A fifth slider insert 5 is provided on a side of the first slider seat 301 that slides relative to the second slider seat 310 , and a groove 51 is provided at a position opposite to the second slider seat 310 and the fifth slider insert 5 . The fifth slider insert 5 is a boss protruding from the surface of the first slider seat 301 , and the groove width of the groove 51 is larger than the width of the boss. When opening the mold, the first slider seat 301...

Embodiment 3

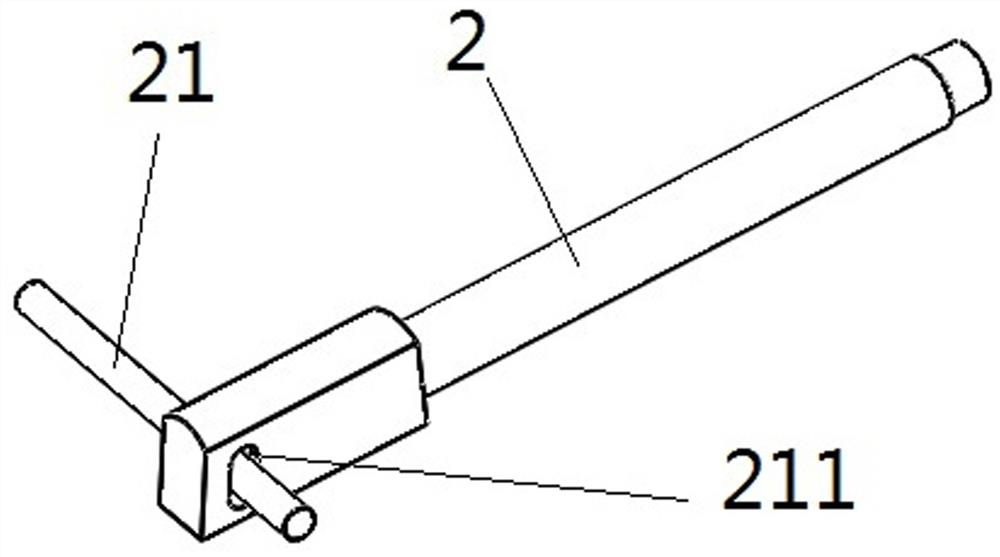

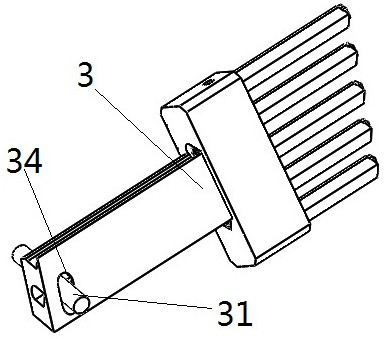

[0042] combined with Figure 2-5 , a demoulding structure with core-pulling at four angles on the side of the air outlet shell of this embodiment, compared with the technical solution of Embodiment 1 or 2, the second slider insert 2 is provided with a second positioning pin 21 and The first U-shaped hole 211, the third slider insert 3 is provided with a third positioning pin 31 and the second U-shaped hole 34, and the first slider seat 301 is respectively provided with a The first groove and the second groove of the piece 2 and the third slider insert 3, the second positioning pin 21 is set in the first groove, and the third positioning pin 31 is set in the second groove. The second slider insert 2 and the third slider insert 3 are respectively fixed on the first slider seat 301 through the second positioning pin 21 and the first U-shaped hole 211, the third positioning pin 31 and the second U-shaped hole 34. superior. When fixing, the second positioning pin 21 passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com