Method for calculating strength of main shaft of wind turbine generator set

A wind power generation unit, strength calculation technology, applied in the direction of calculation, electrical digital data processing, special data processing applications, etc., can solve the problems of increased structural size, insecurity, performance impact and transmission, etc., to achieve cost saving and accurate calculation , time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

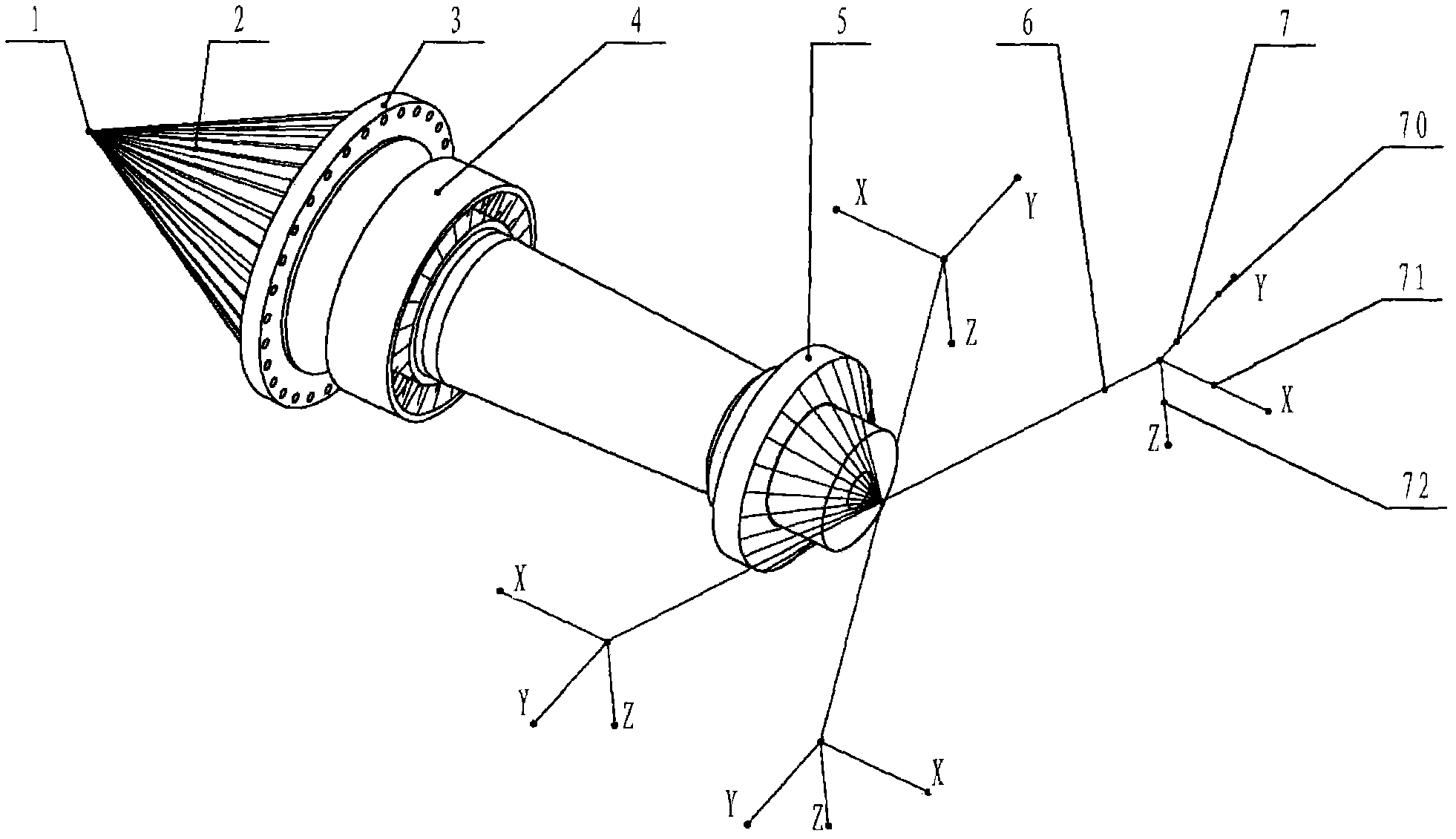

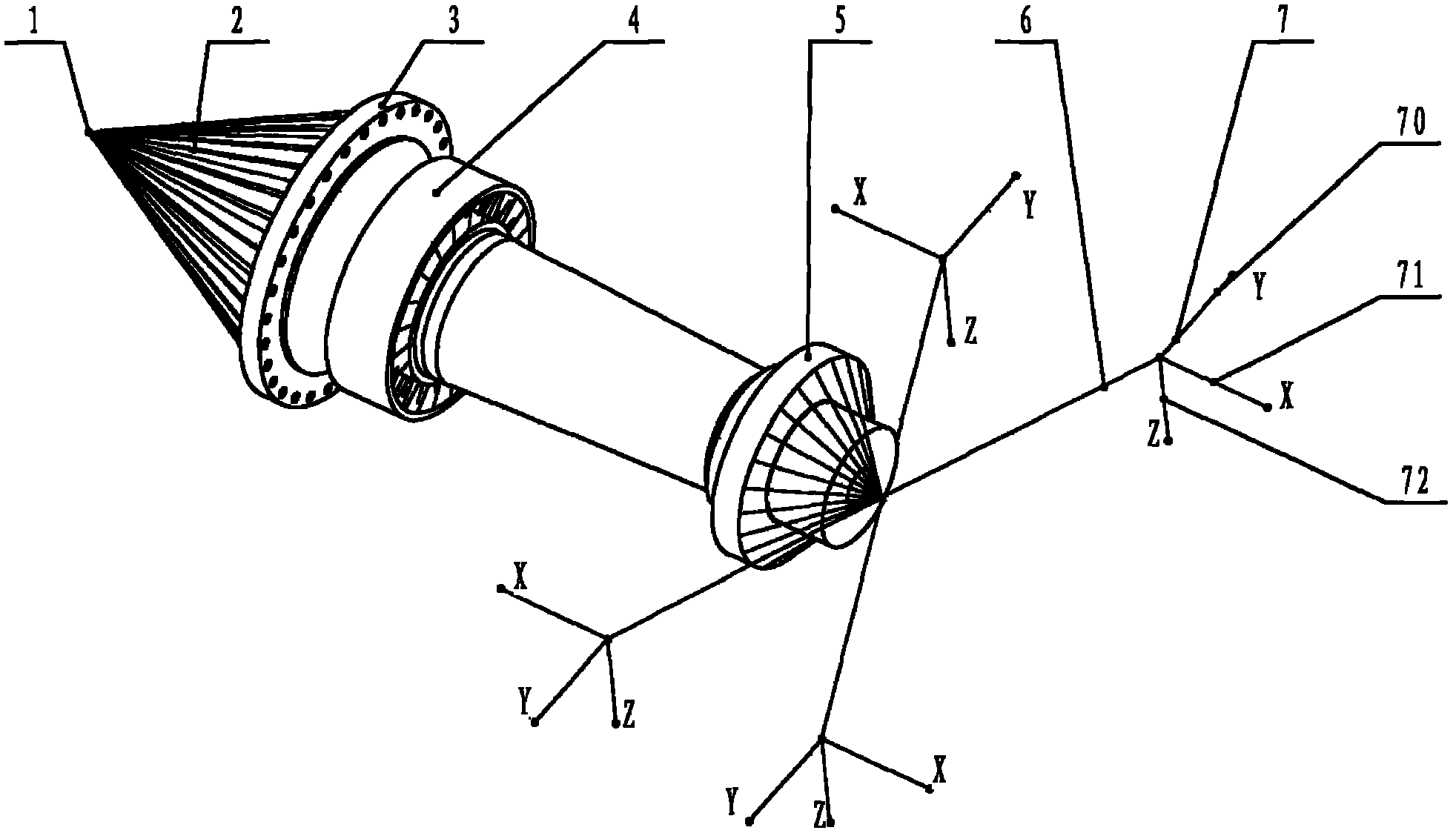

[0019] Such as figure 1 As shown, the method for calculating the main shaft strength of the wind power generating set according to the present invention, its steps mainly include:

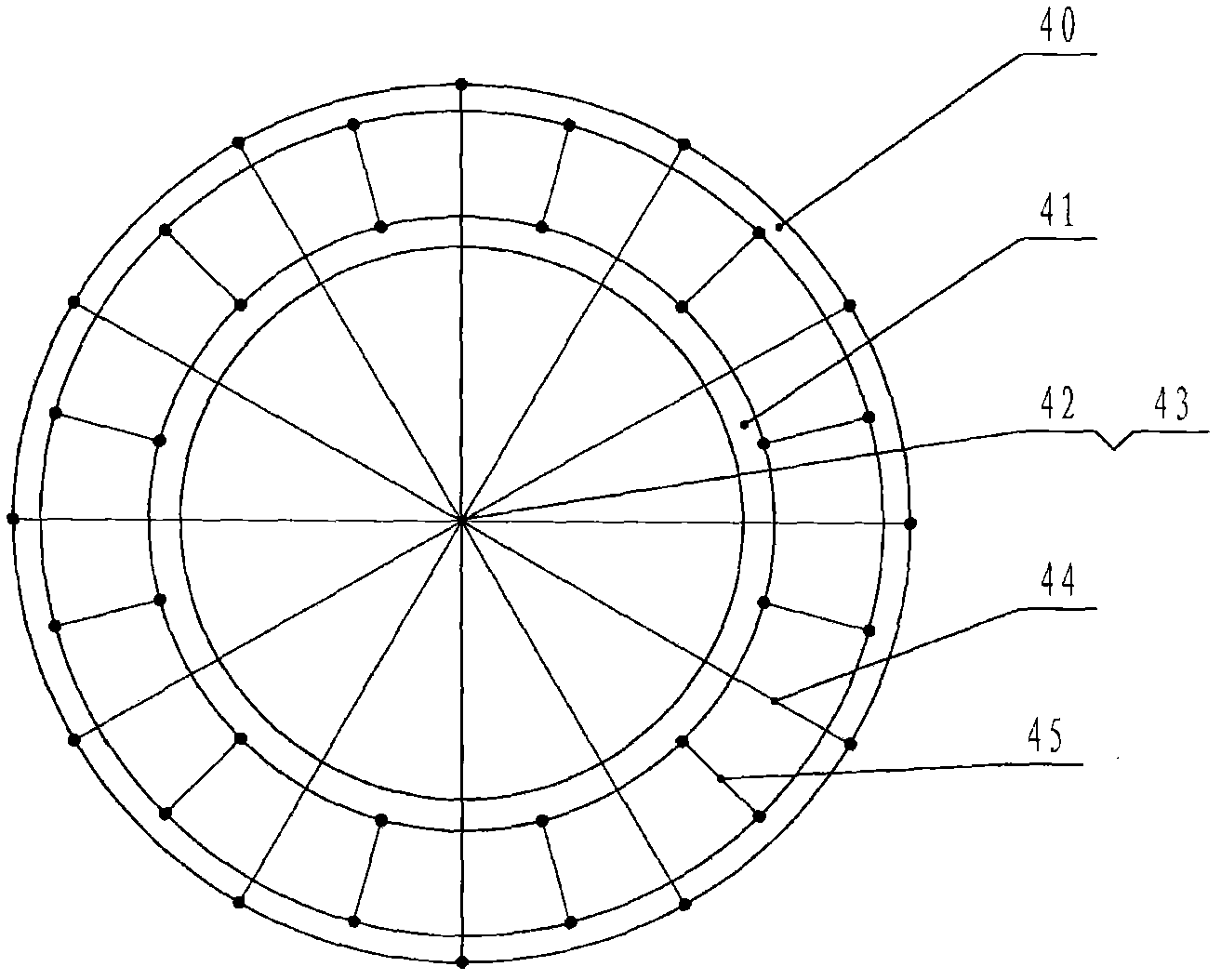

[0020] (1) Using the existing finite element software as a platform to implement modeling, firstly, the main shaft 3, bearing 4 and locking disc 5 are combined into one structure with solid element simulation settings, and the solids can be combined by node merging. The bearing 4 and the locking disc 5 are solidly modeled, which can effectively reduce the stress concentration problem at the contact position; the wind wheel part is simulated to set a wind wheel node 1 and its position is the center point of the wind wheel;

[0021] (2) Secondly, four gear box elastic supports are arranged outside the locking disc 5, and the elastic support of each gear box is simulated by the spring unit group 7, and the flange bolt holes of the wind wheel node 1 and the main shaft 3 are connected by the rigid beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com