Step type spark plug

A spark plug and spark gap technology, used in the field of spark plugs, can solve problems such as being unsuitable to ensure a stable combustion process, incomplete combustion process, misfire, etc., and achieve the effects of preventing incomplete combustion or even flameout, reducing fuel combustion and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

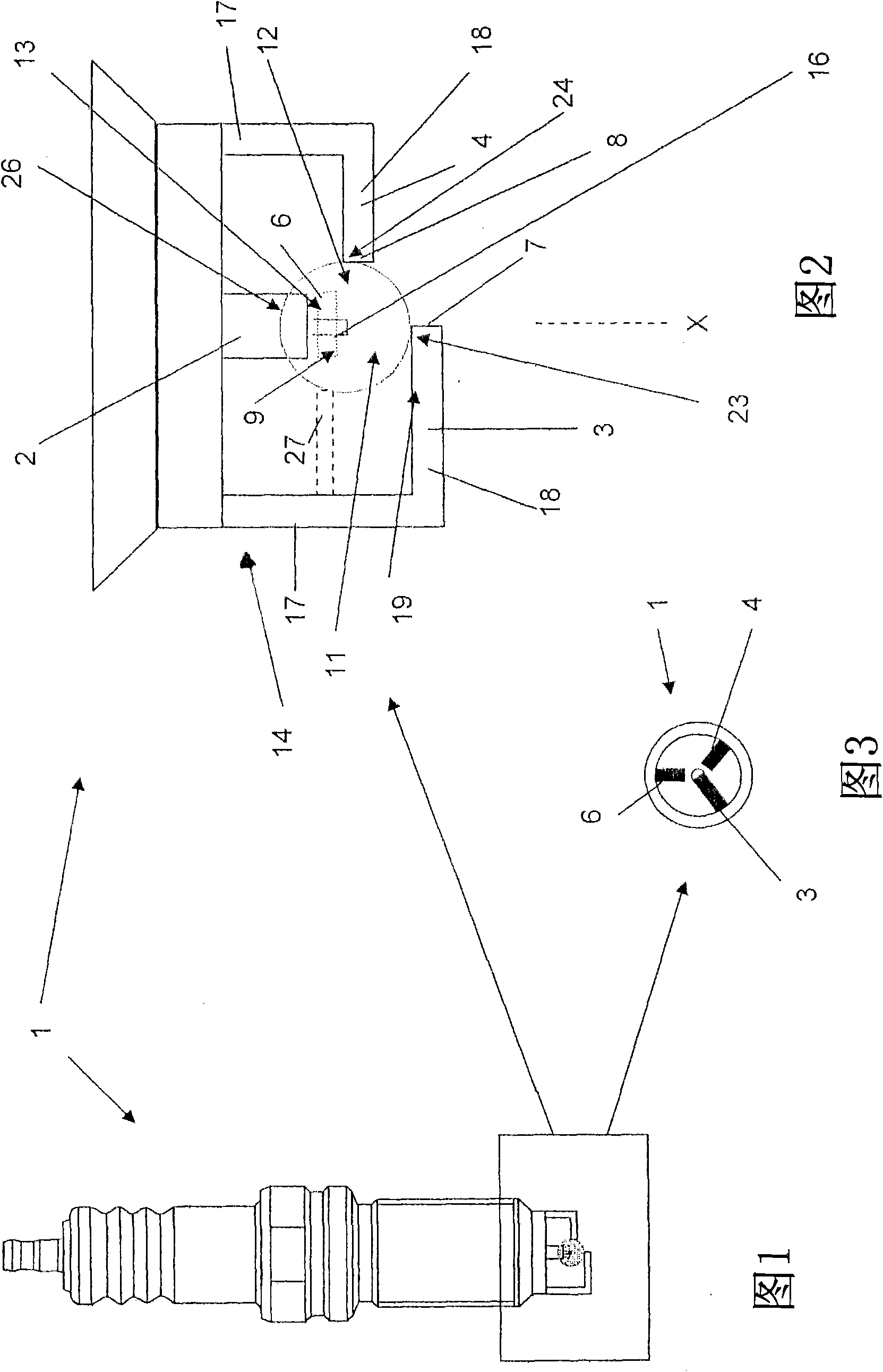

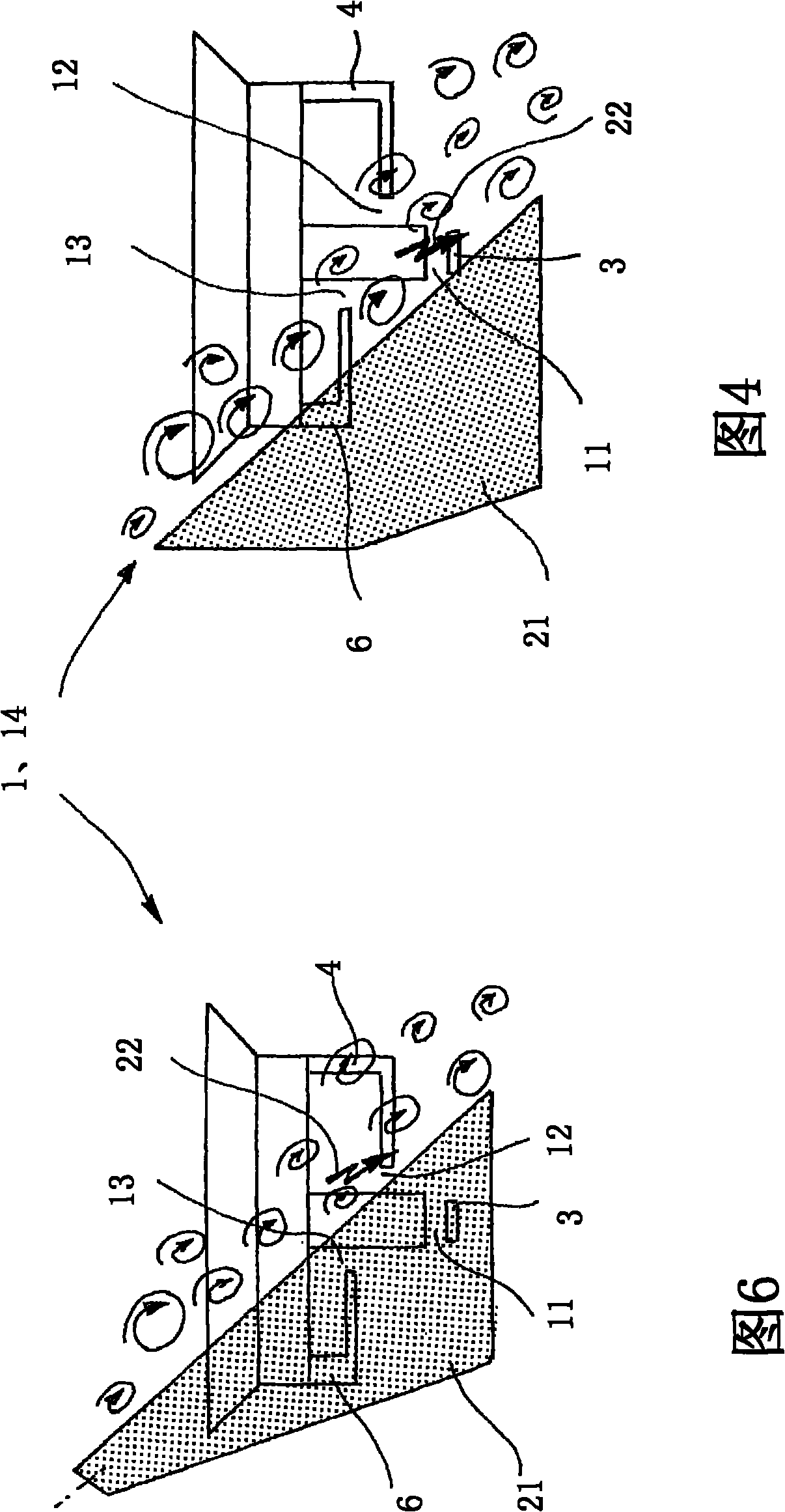

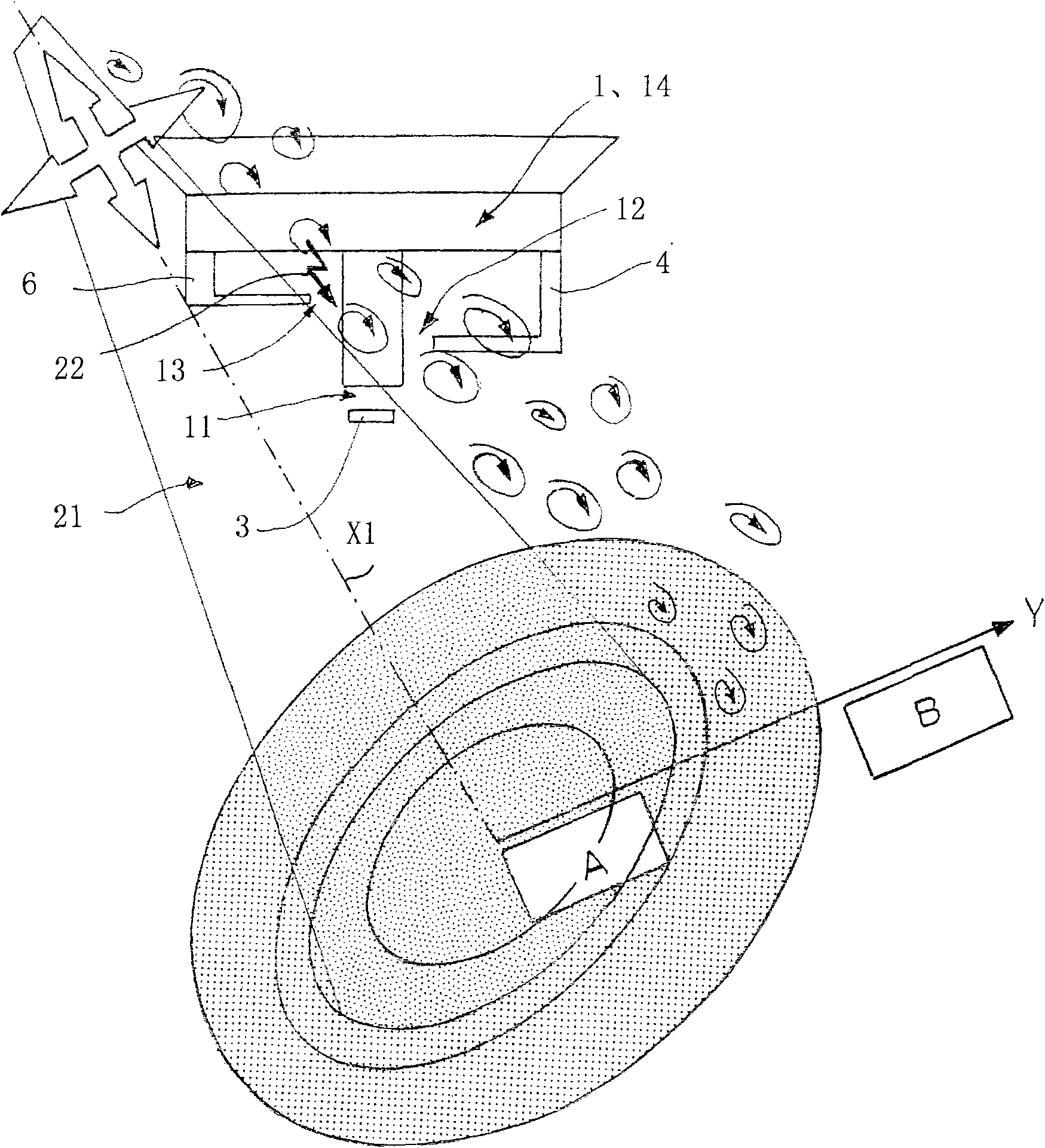

[0031] Figure 1 to Figure 3 Shown is a spark plug 1 comprising a center electrode 2 and a top electrode 3 as well as at least two side electrodes 4, 6 as ground electrodes, both side electrodes 4, 6 and top electrode 3 having exposed sides oriented towards the center electrode 2 (face edge) 7, 8, 9. The side electrodes 4 , 6 embodied as ground electrodes are each arranged with their exposed sides 8 , 9 around the central axis X of the central electrode 2 with lateral spacing, and they are axially spaced apart from each other in such a way Such that the respective exposed sides 7 , 8 , 9 are each arranged at different height levels, so that the spark gaps 11 , 12 , 13 formed are all spatially independent of each other.

[0032] The selected view means that only side electrode 4 of side electrodes 4 and 6 is fully visible. As for the side electrodes 6, only the end faces (indicated by dotted lines) of their exposed sides 9 can be seen.

[0033] The center electrode 2 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com