Method for analysis of color separations

A color separation, color measurement technology, applied in the field of color separation analysis, can solve different problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

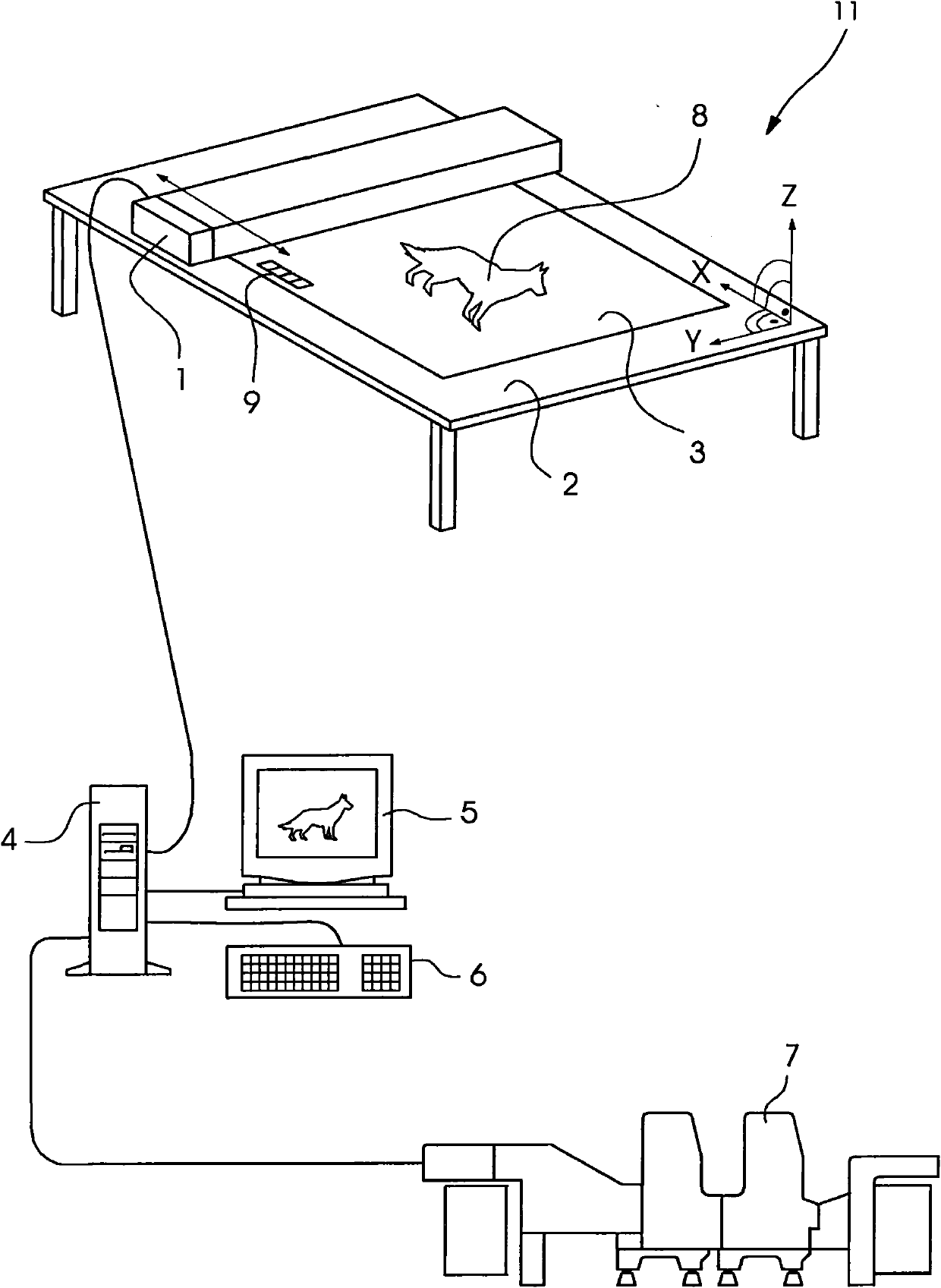

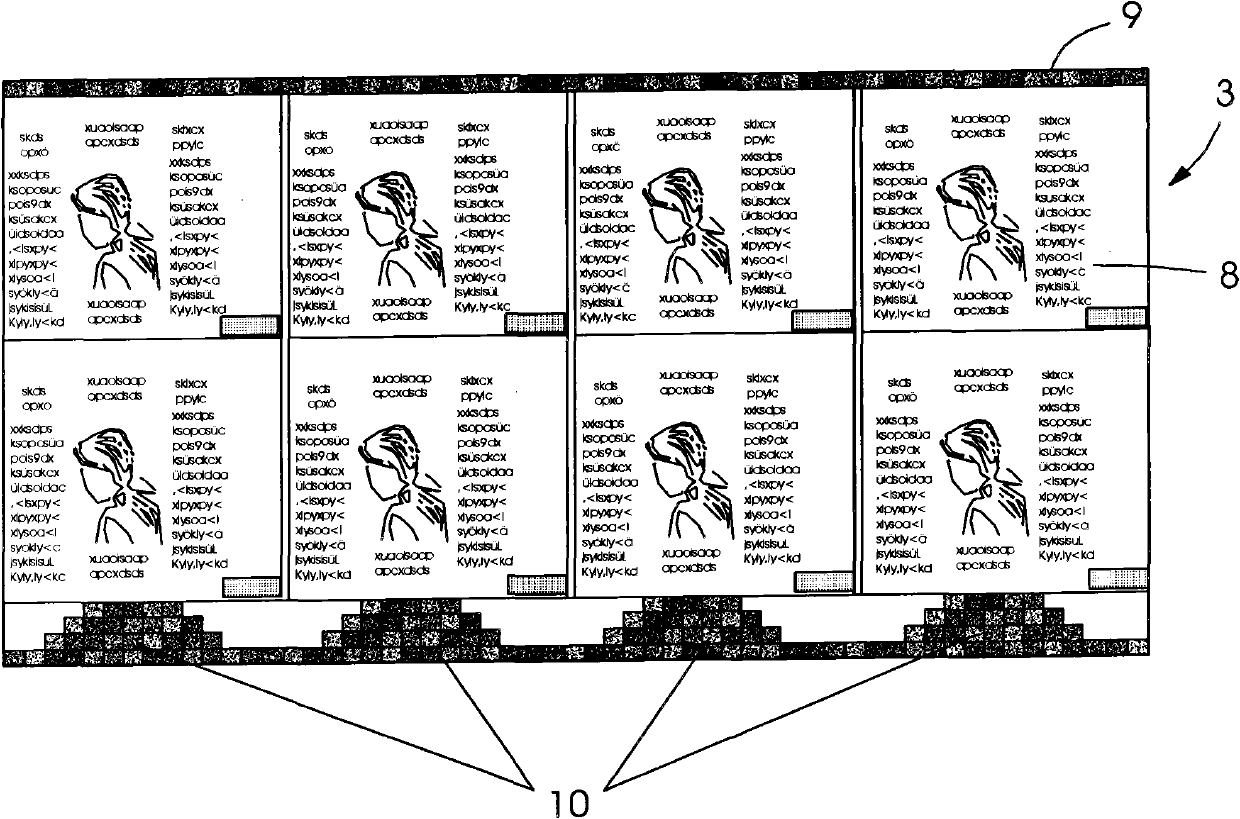

[0026] figure 1 An offset printing press 7 with two printing units is shown, the controller of which is networked with the computer 4 . Also connected to the computer 4 is a color measuring device 11 which can measure the sheet-shaped printing material 3 flatly during the scanning process. For this purpose, measuring beam 1 configured as a scanner moves over the entire sheet 3 in the x-direction and detects here not only the entire printed image 8 but also laterally arranged printing control strips 9 on the sheet 3 . The sheets are laid flat on the measuring table 2 during the measuring process. In this way, both the entire printed image 8 and the laterally arranged printed control strips 9 can be detected by scanning the measuring beam 1 in one pass. The data of the printed image 8 and the printed control strip 9 detected in this way can then be transmitted to the computer 4 , where the actual measured values detected in this way are compared with the corresponding desire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com