Transmission roller mold

A technology for conveying rollers and moulds, which is applied in manufacturing tools, ceramic molding machines, etc., and can solve problems such as air bubbles, insufficient compaction, and air mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

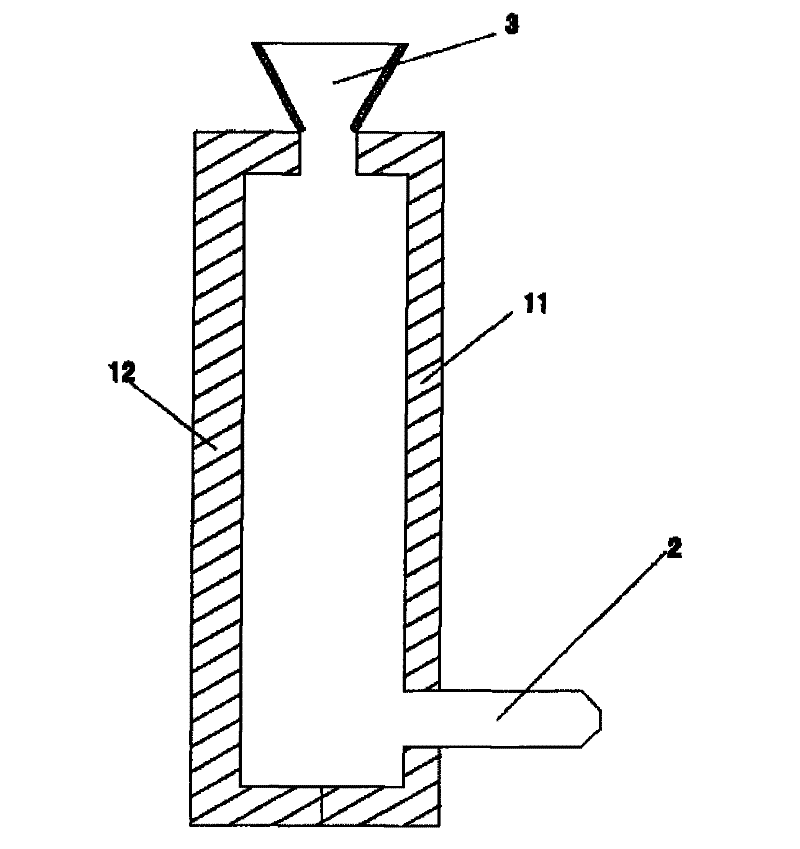

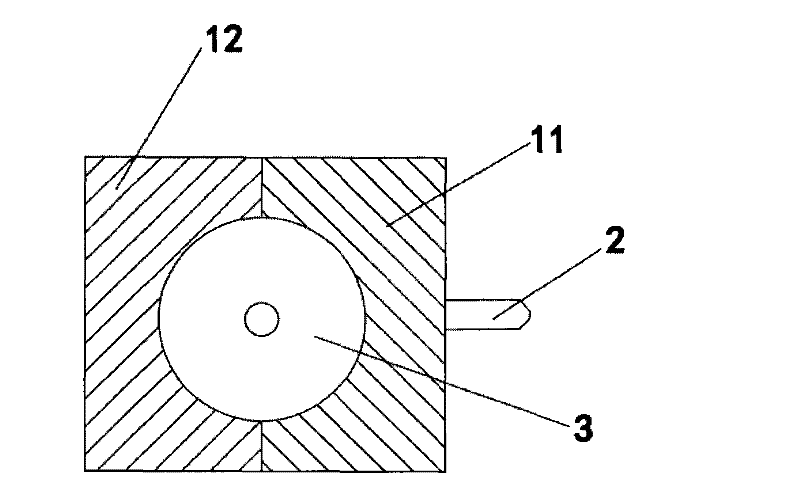

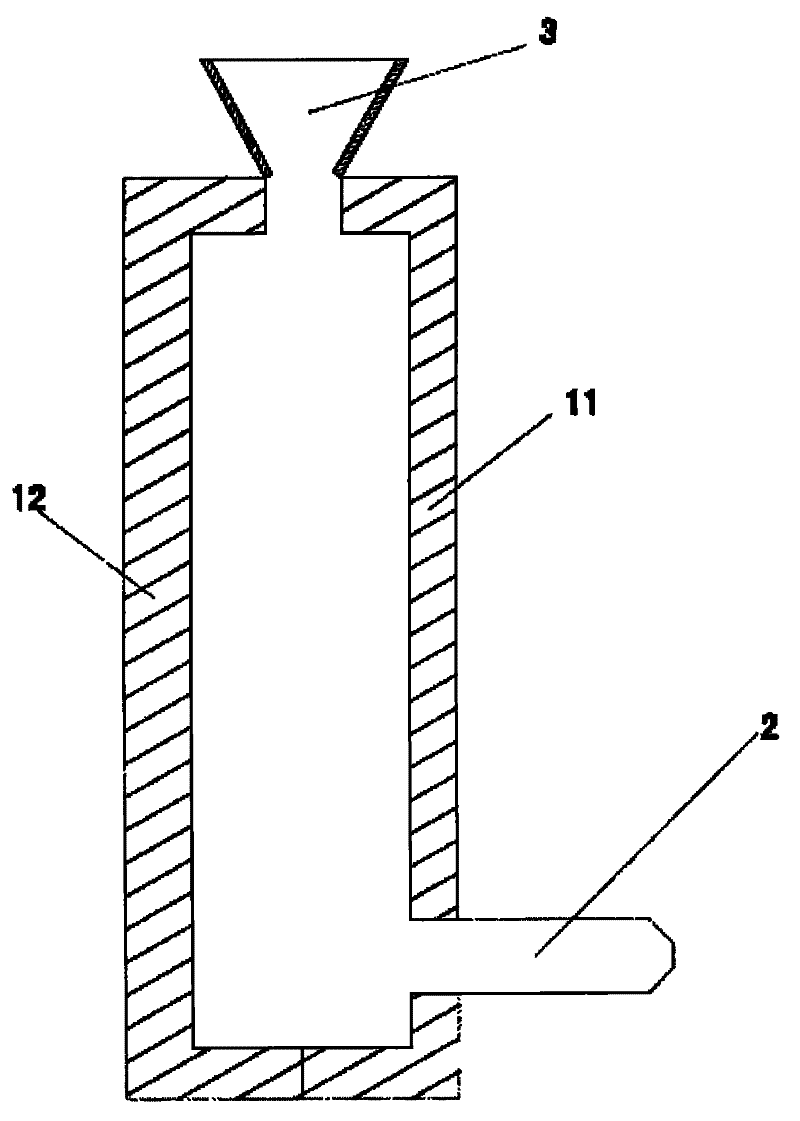

[0017] The present invention discloses a transfer roller mould, which comprises a first mold 11 and a second mold (12). The first mold 11 and the second mold 12 are closed and tightened by a tightening belt (not shown in the figure). After the mold, a cylindrical mold core with a circular opening at the upper end and a closed lower end is formed. A circular tube protrudes from the bottom of the first mold 11 to form an injection device 2 , and a funnel 3 is provided at the top of the mold. The lower end opening of the funnel 3 communicates with the circular opening behind the mold closing.

[0018] When the mold is in use, the first mold 11 and the second mold 12 are first tightened by a tightening belt, and the slurry is injected into the mold from the injection device 2 below the first mold 11 through a vacuum pump. When the slurry is full of the mold, it will cause the backflow of the material when it is left to form the mold. In order to prevent the backflow from causing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com