Conveyor belt longitudinal tear detection device based on dual vision image feature fusion

A technology of image features and longitudinal tearing, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of poor practicability and poor pertinence, and achieve the goal of improving reliability, enhancing spectral information, and enriching image information Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

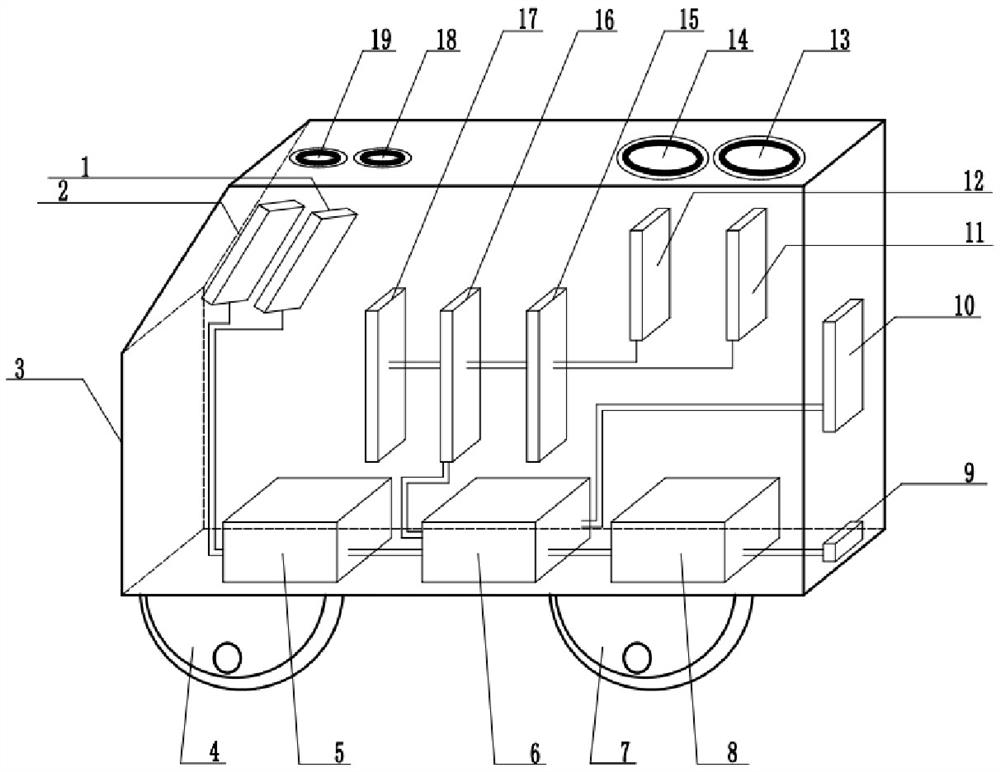

[0029] Such as Figure 1~3 As shown, it is a schematic structural diagram of a conveyor belt longitudinal tear detection device based on dual vision sensors provided in Embodiment 1 of the present invention; it includes a housing 3, and the housing 3 is fixedly equipped with an infrared light emitting module 1, a visible light Emitter module 2, power supply module 5, infrared light detection module 11, visible light detection module 12, collected data preprocessing module 15, storage module 17 and data processing module 16, the described housing is provided with infrared light emission glass window 18, visible light Emitter glass window 19 , infrared light detection glass window 13 , visible light detection glass window 14 and fixed base 4 .

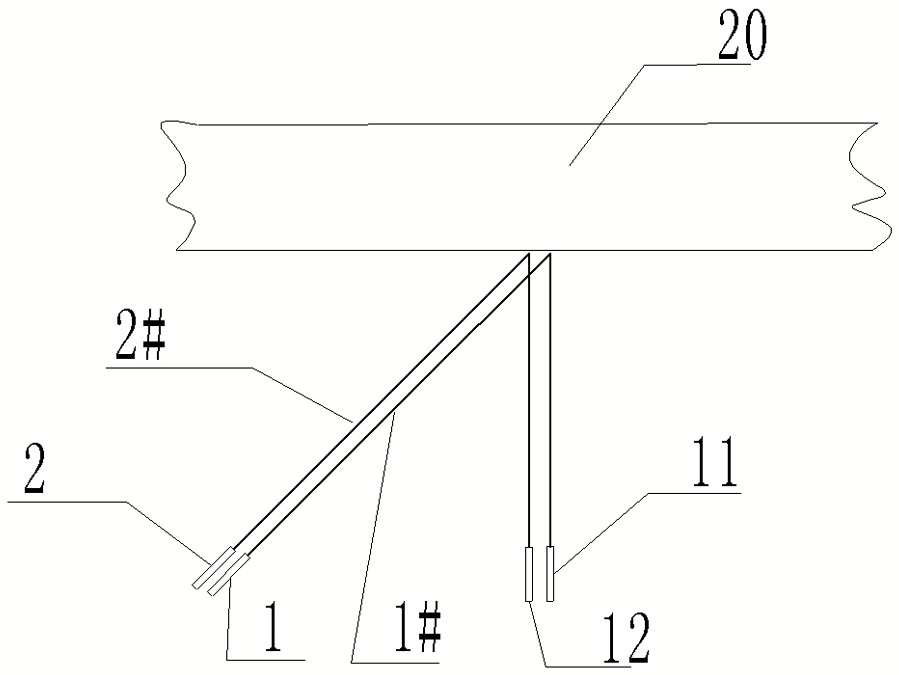

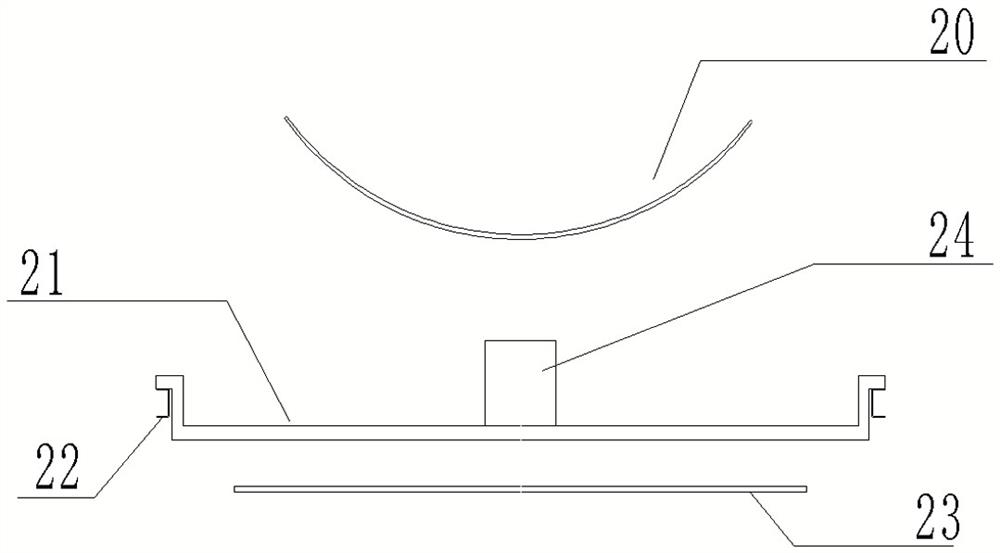

[0030] Such as figure 2 and image 3 As shown, the housing 3 is fixed on the connecting bracket 21 below the upper conveyor belt 20 through the fixed base 4, and the inline beams emitted by the infrared light emitting module 1 and the...

Embodiment 2

[0067] In this embodiment, the width of the detected conveyor belt is 800 mm, and the running speed of the conveyor belt is 6.0 m / s. The device is installed in the middle of the connecting bracket between the conveyor belt racks, and the upper surface of the device is 550mm away from the lower surface of the upper conveyor belt. The frame rate of the collected image is 17 frames / s, and other parameters are the same as those in Example 1. In this example, the detection device can detect the longitudinal tear of the conveyor belt with an accuracy of over 98% when the conveyor belt is running fast.

Embodiment 3

[0069] In this embodiment, the width of the detection conveyor belt is 1600mm, and the running speed of the conveyor belt is 6.0m / s. Two sets of devices are used to install on the left and right sides of the connecting bracket between the large conveyor belt racks respectively. The distance between the upper surface of the device and the lower surface of the upper conveyor belt is 550mm. In this embodiment, two sets of detection devices are used to simultaneously detect the longitudinal tear of the large belt running at high speed, and the detection accuracy rate is above 98%.

[0070] The present invention makes full use of the advantages that infrared light has good thermal imaging and penetrability, and visible light images have better detailed information, reflecting the real environment target situation, and performs feature-level fusion of infrared light images and visible light images to enrich image information , enhance the spectral information of the image, make up f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com