Design method for interference-free installation of gear tooth phase of internal gear ring plate in outer three-ring speed reducer

A design method and technology of internal gear ring, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of lack of three-phase internal gear ring plate and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

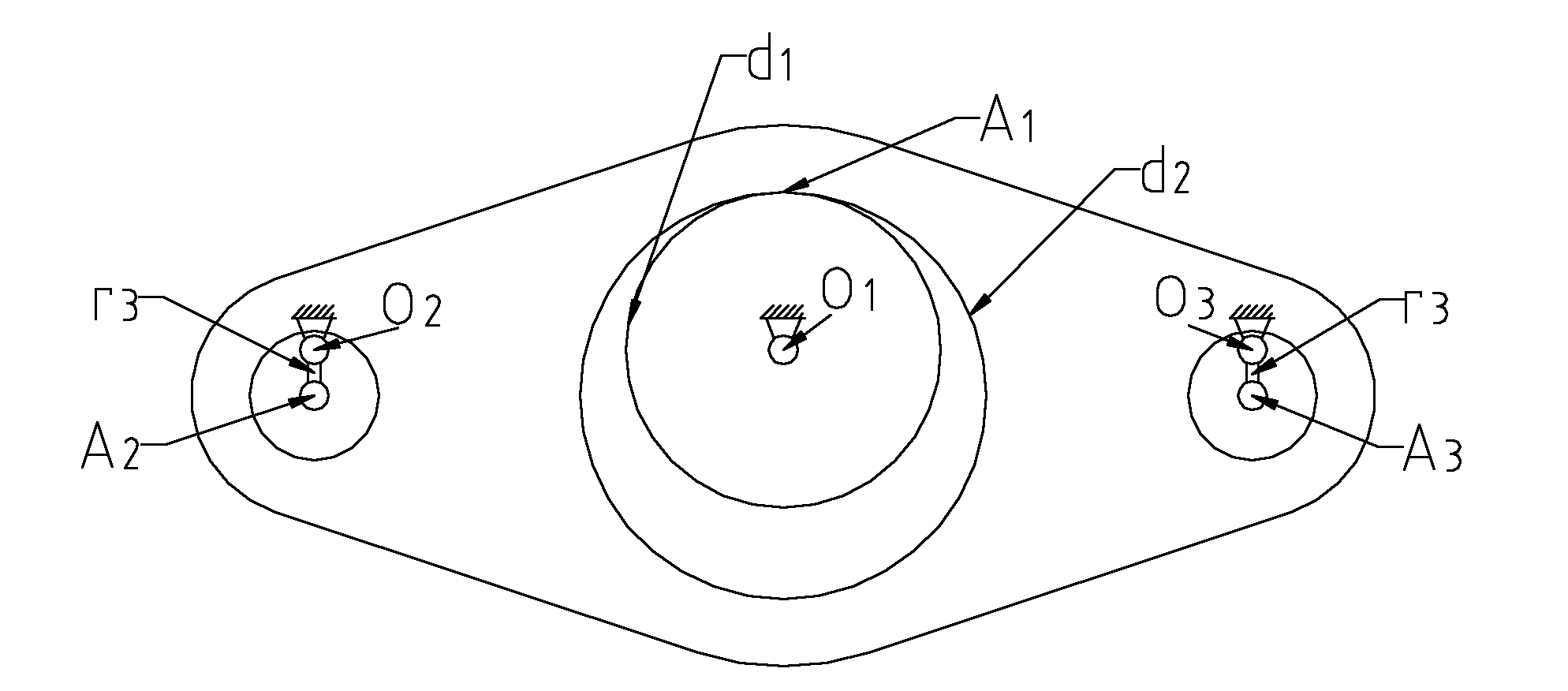

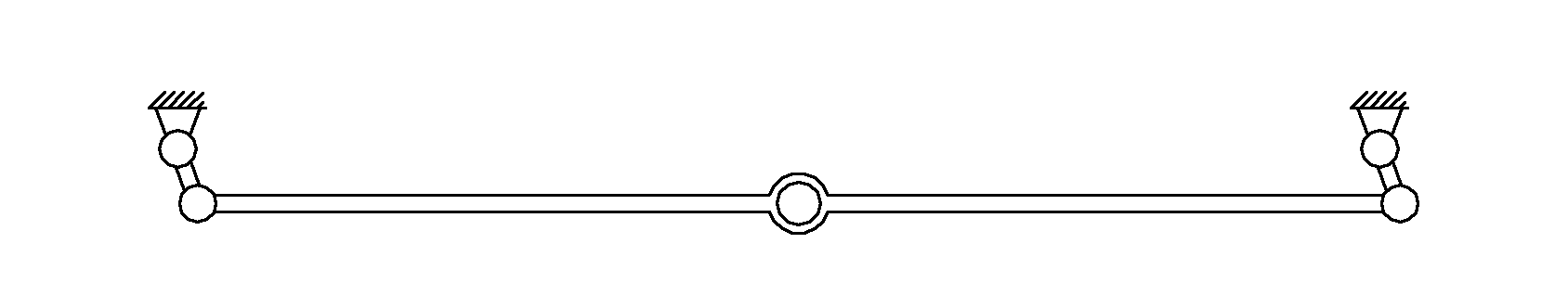

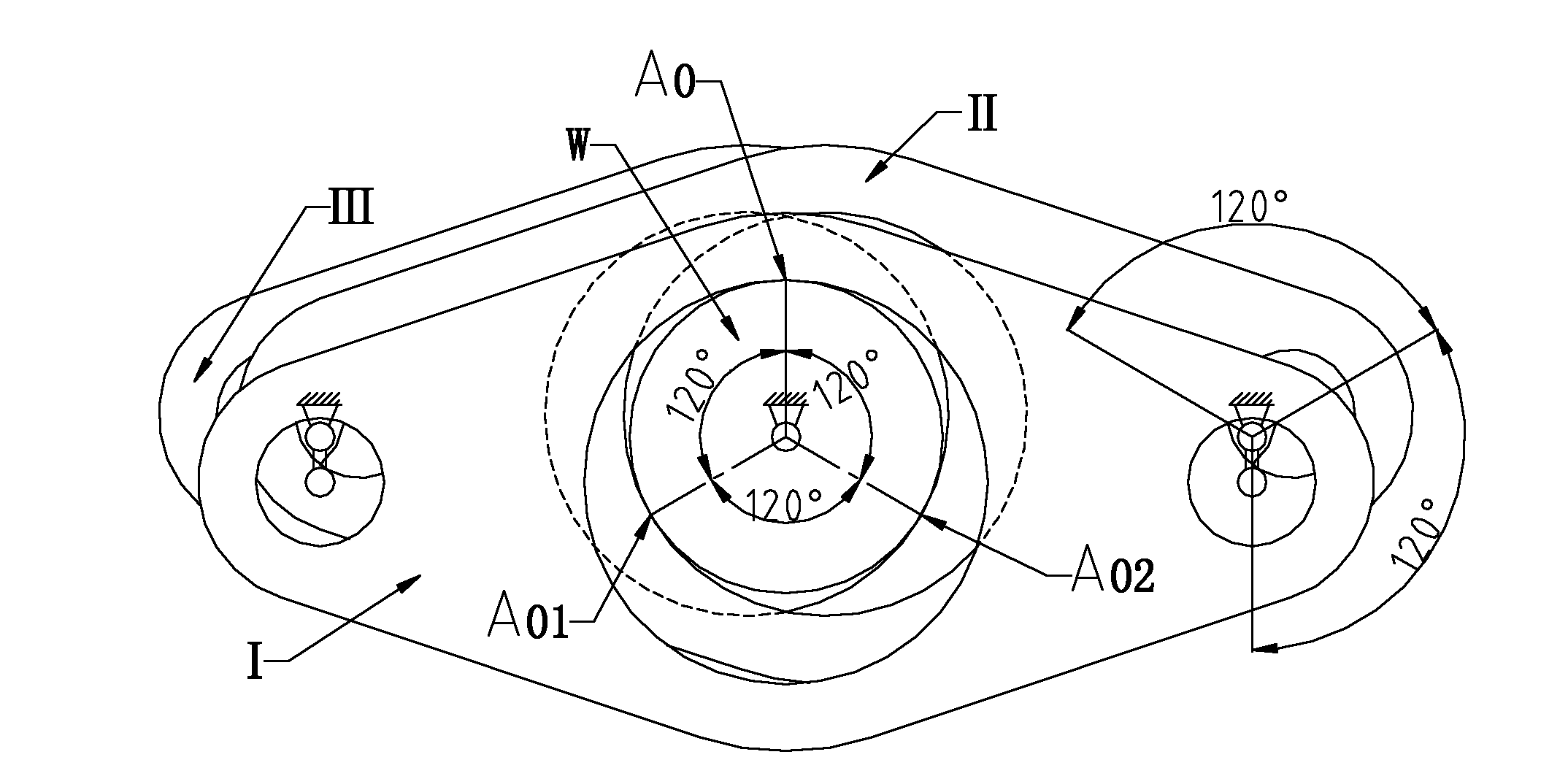

[0130] The present invention relates to the gear tooth phase technology for the non-interference assembly of the three-phase inner gear ring plate of the outer three-ring reducer. Before that, because there was no relevant theoretical support, whether it is in the design stage or in production, it can be said that it is related to this The solution to the problem is in a state of blindness. The method of the invention can effectively solve this problem.

[0131] The content of the design method for the non-interference installation of the tooth phase of the inner gear ring plate of the outer three-ring reducer provided by the present invention is as follows:

[0132] 1. Determination of the tooth phase angle of the inner gear ring plate of the outer three-ring reducer, also known as the spin angle

[0133] Based on the first (No. 0) inner gear ring plate, determine the phase angle Pn of the second (No. 1) and third (No. 2) inner gear ring plate teeth according to the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com