Operation wire harness connection device and endoscope

A technology of connecting device and endoscope, applied in the field of endoscope, can solve the problems of inability to adjust the spacing between teeth, inability to adjust, and inability to precisely adjust the loosening of operating wire harnesses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

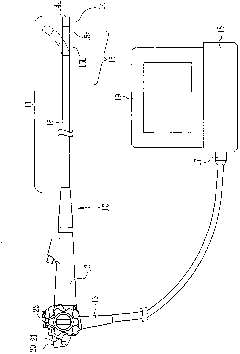

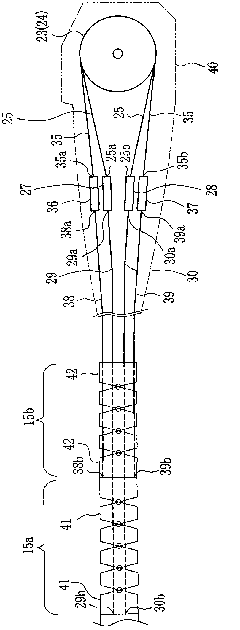

[0034] exist figure 1 Among them, an endoscope 10 includes an elongated insertion portion 11, an operation portion 12 provided on the proximal end side of the insertion portion 11, a universal cord 13, and the like. The insertion part 11 is formed in a tubular shape and includes a front end part 14 , a curved part 15 , and a flexible part 16 in this order from the front end. The bending portion 15 includes a first bending portion 15a that is bent in the vertical direction and a second bending portion 15b that is bent in the left-right direction. One end of the universal cord 13 is connected to the operation unit 12 , and the connector unit 17 at the other end is connected to the processor unit 18 , air supply unit (not shown), light source unit (not shown), and the like.

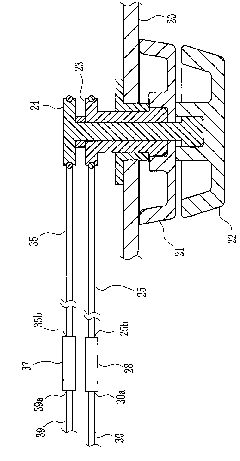

[0035] The front end portion 14 has a cap shape formed of a hard resin material. As is well known, the front end surface 14a of the front end portion 14 is provided with an illumination window for irradiat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com