Micro flapping wing air vehicle

A flapping-wing aircraft and miniature technology, applied in the field of flapping-wing aircraft, can solve the problems of energy consumption, low efficiency of turbine and worm transmission, and disadvantage to the miniaturization of flapping-wing aircraft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

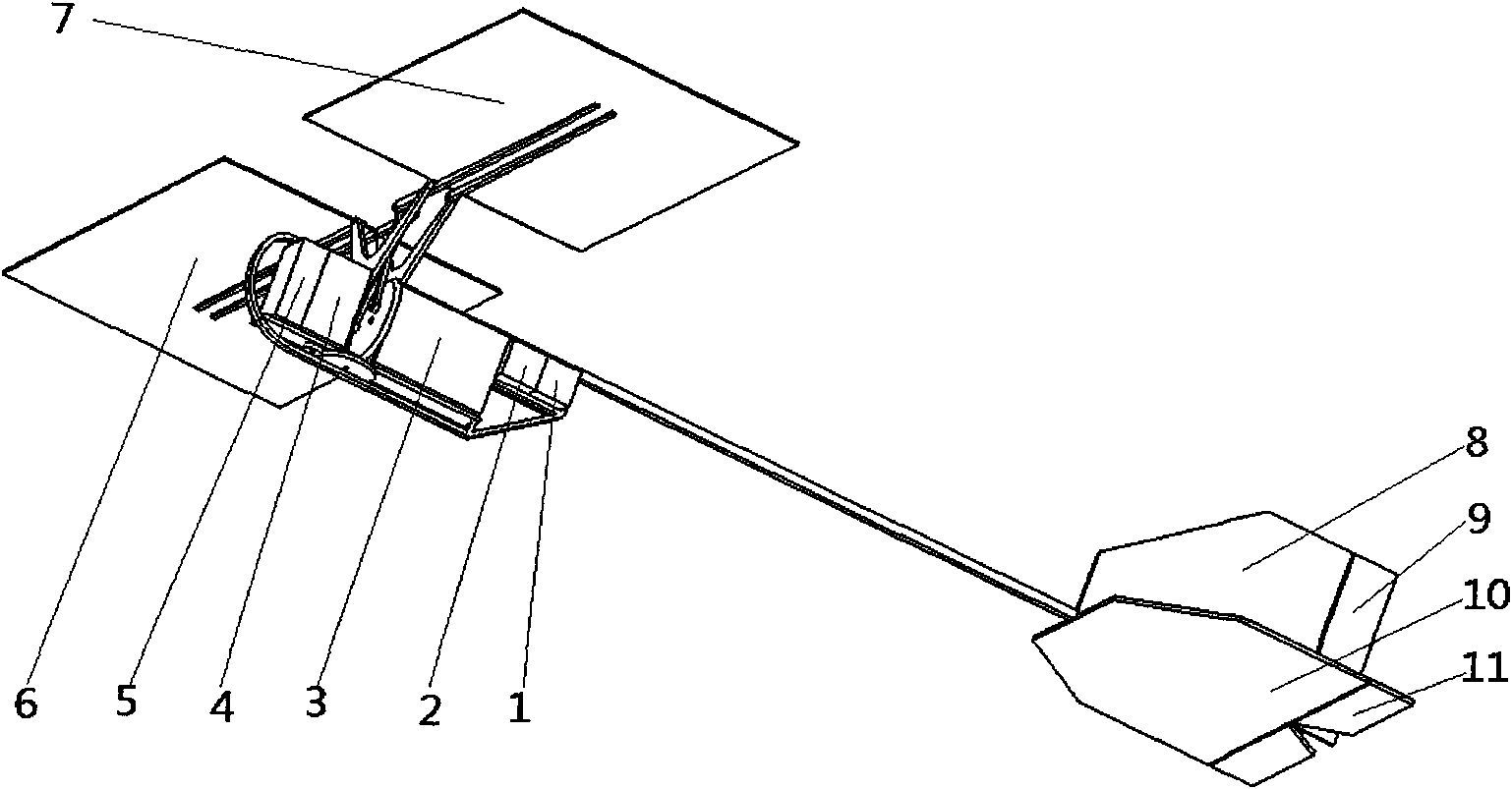

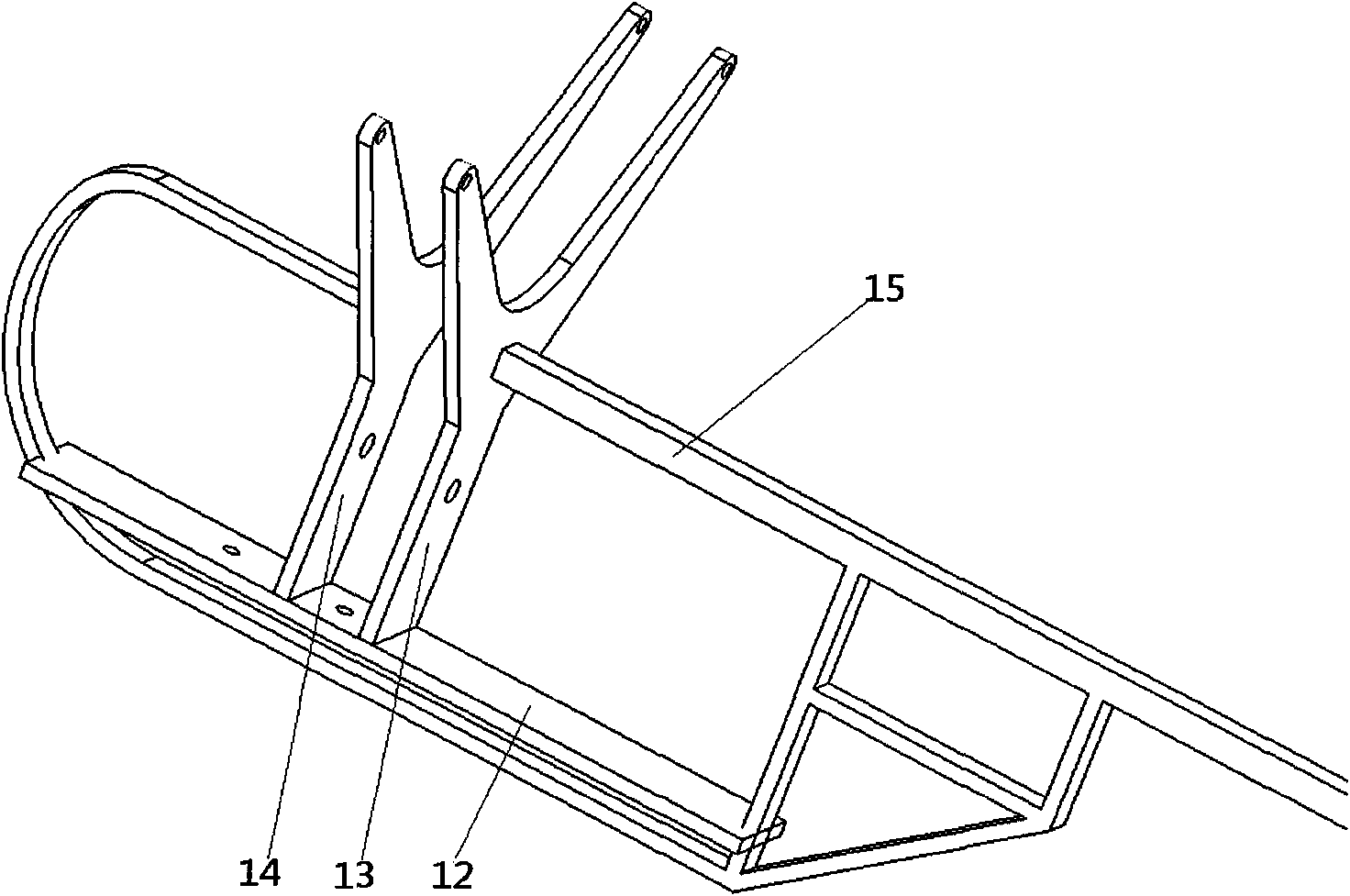

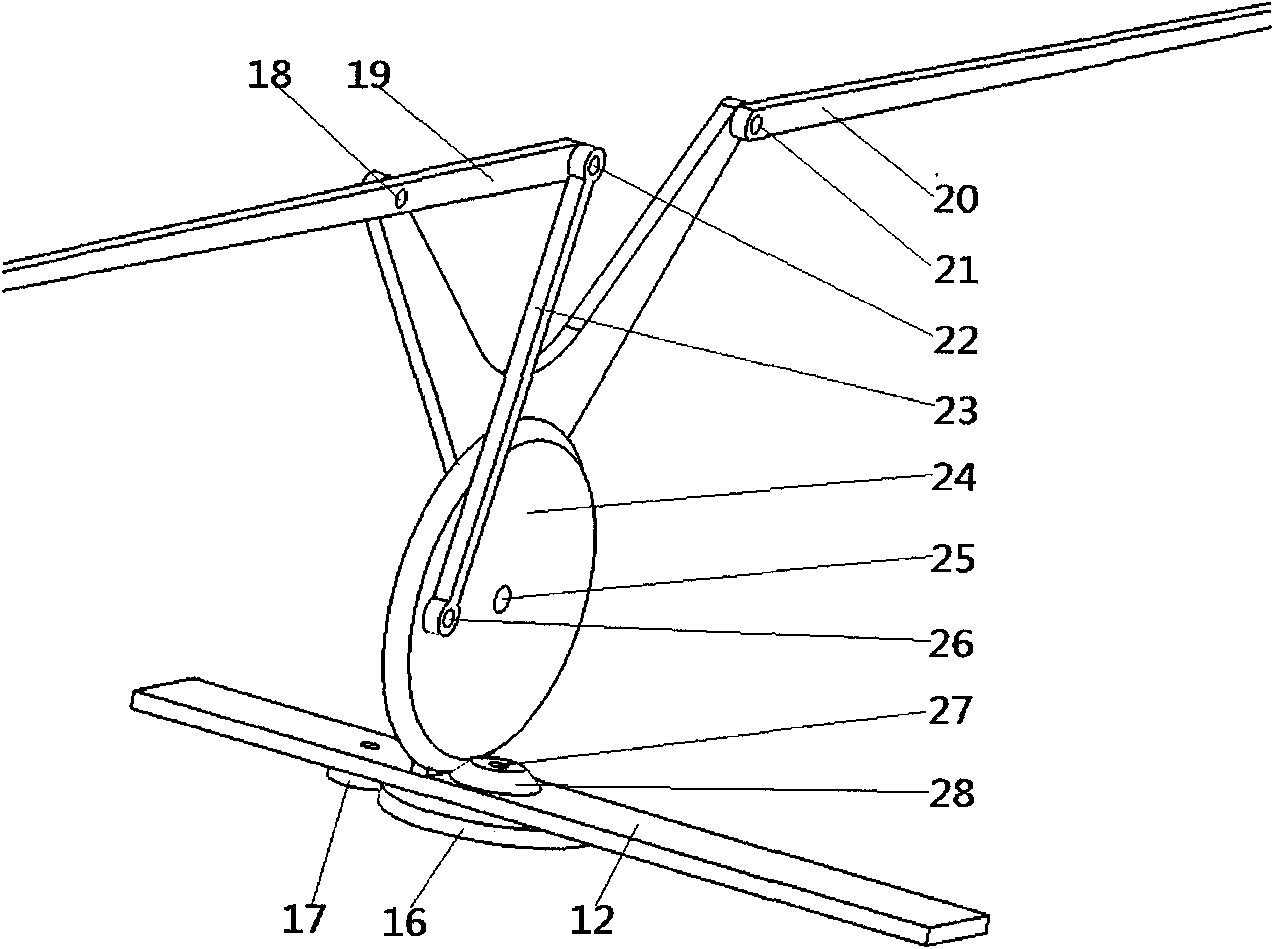

[0026] The present invention is mainly made up of frame, left flapping wing system, right flapping wing system and empennage system. The frame is mainly composed of Y-shaped front bracket 14, supporting base plate 12, Y-shaped rear bracket 13, and external main bracket 15; Gear 28, bevel gear a24, pin d25, pin e26, connecting rod a23, pin c22, pin a18, left driving rocker 19, pin g32, left driven rocker 31, left flapping wing 7 and The control module 5 and the battery 3 are composed; the right flapping wing system is mainly composed of a motor 4, a small gear 17, a large gear 16, a transmission shaft 27, a small bevel gear 28, a large bevel gear b35, a pin shaft i36, a pin shaft j37, and a connecting rod b34 , pin h33, pin f29, right active rocker 30, pin b21, right driven rocker 20, right flapping wing 6, control module 5, and battery 3; the tail system is mainly composed of steering gear 1 and vertical stabilizer 8, the steering system that rudder 9 forms and the lifting sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com