Connecting device of novel press connecting rod and sphere lead screw

A connecting device and press technology, which is applied to the driving device of forging presses, presses, stamping machines, etc., can solve the problems of difficult adjustment of threads, damage, equipment damage, etc., and achieve the effect of avoiding excessive local stress on threads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

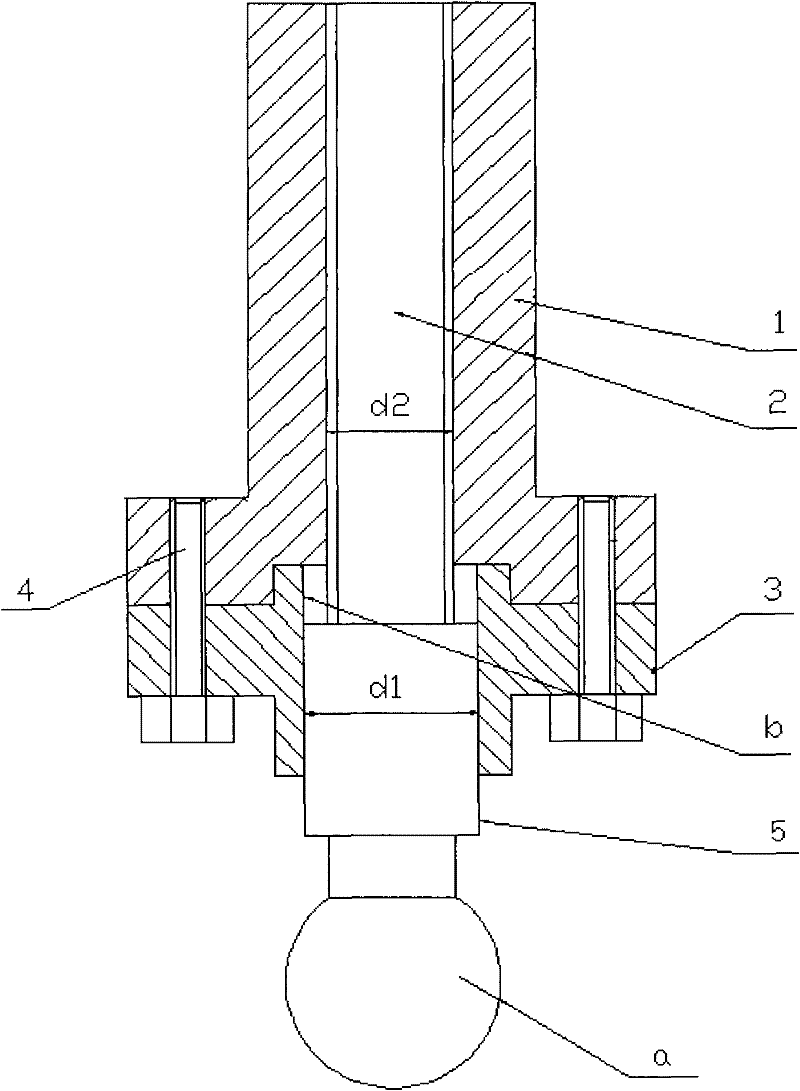

[0008] Fix the positioning flange (3) to the lower port of the connecting rod (1) with bolts (4), and install the ball screw (2) to the connecting rod through the middle hole of the positioning flange (3) In the threaded hole of (1); in the part of the ball screw rod (2) close to the ball head a, a ball head light cylinder (5) is made, and the size d1 of the ball head light cylinder (5) is consistent with the positioning flange (3) The free dimensions of the center b of are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com