Tool plate-free leakage detection logistics system and leakage detection method

A leak detection and logistics system technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, can solve the problems of low leak detection efficiency and complicated leak detection process, and achieve the effect of improving leak detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

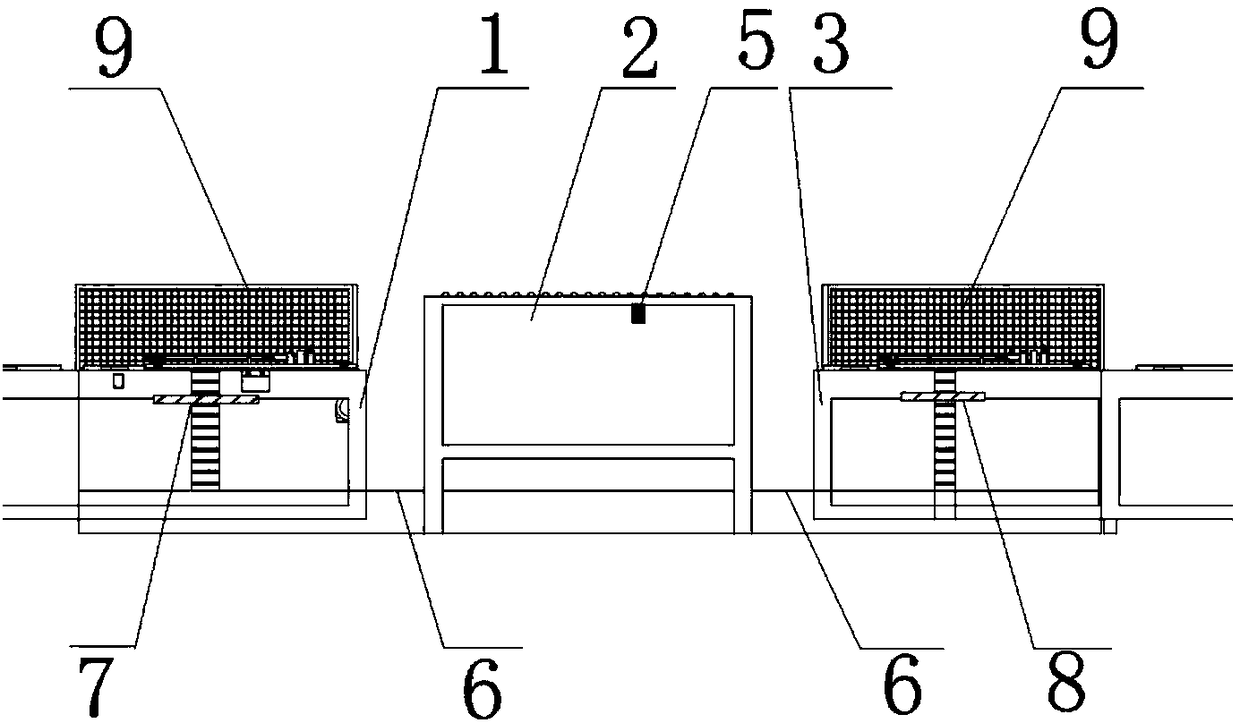

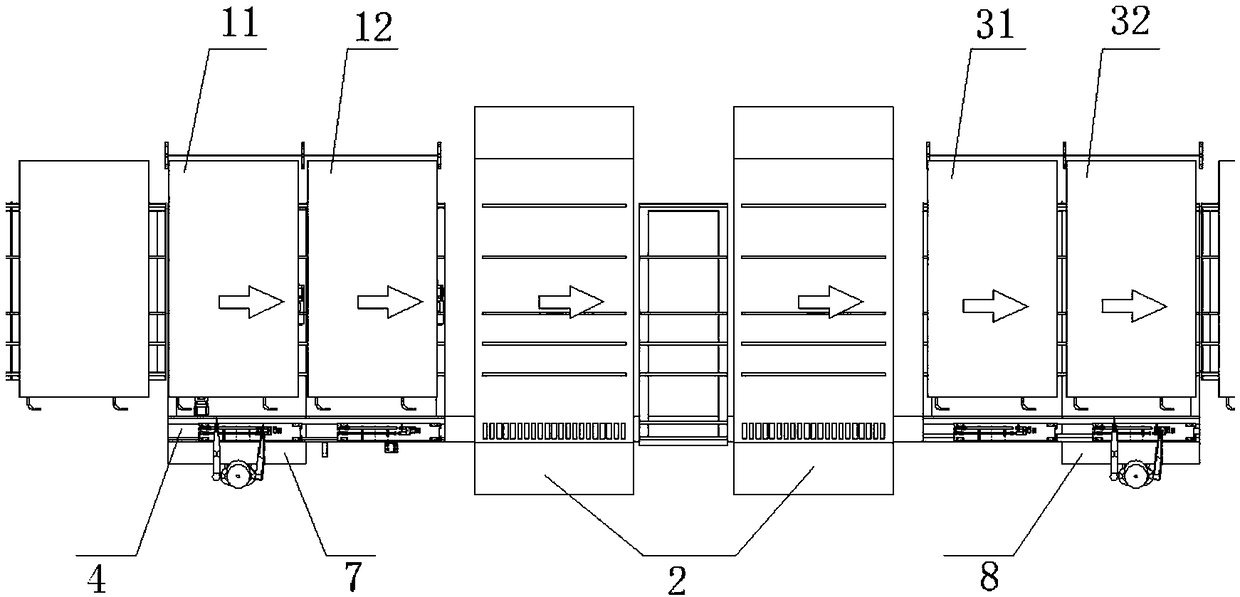

[0019] This embodiment provides a non-tooling plate leak detection logistics system, such as figure 1 As shown, it includes an input device 1, a vacuum leak detection device 2, and an output device 3 that are arranged in sequence to form an automatic leak detection assembly line. The front end of the input device 1 is provided with a positioning tool 4, and the vacuum leak detection device 2 is equipped with a positioning tool. 4 Corresponding positioning automatic plug-in mechanism 5, the lower front end of the output device 3 is provided with a positioning tool return line 6 that is transmitted to the lower front end of the input device 1, and the two ends of the positioning tool return line 6 are respectively arranged with the input device 1 and the output device 3 Lifting mechanism A7 and lifting mechanism B8 corresponding to the front end;

[0020] Wherein, the input device 1 includes a front operation transmission mechanism 11 and a front transition transmission mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com