Novel press machine link mechanism

The technology of a connecting rod mechanism and a press, applied in the field of forging machinery, can solve the problems of thread deformation, eccentric load on the thread, difficult adjustment of the thread, etc., and achieve the effect of avoiding excessive local force on the thread

Inactive Publication Date: 2013-06-05

王传平

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The connecting rod is an important functional part of the press. They transmit pressure by the cooperation of the internal and external threads of the two, and at the same time, the adjustment of the working mechanism of the press is realized by the adjustability between the two threads. At present, in actual use During the process, it often happens that the thread between the two is difficult to adjust, and even the thread is damaged. Since the pressure transmission of the connecting rod is not always along the axis of the two, the stress between the threads occurs. Eccentric load, excessive local force, resulting in deformation or even damage between threads

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

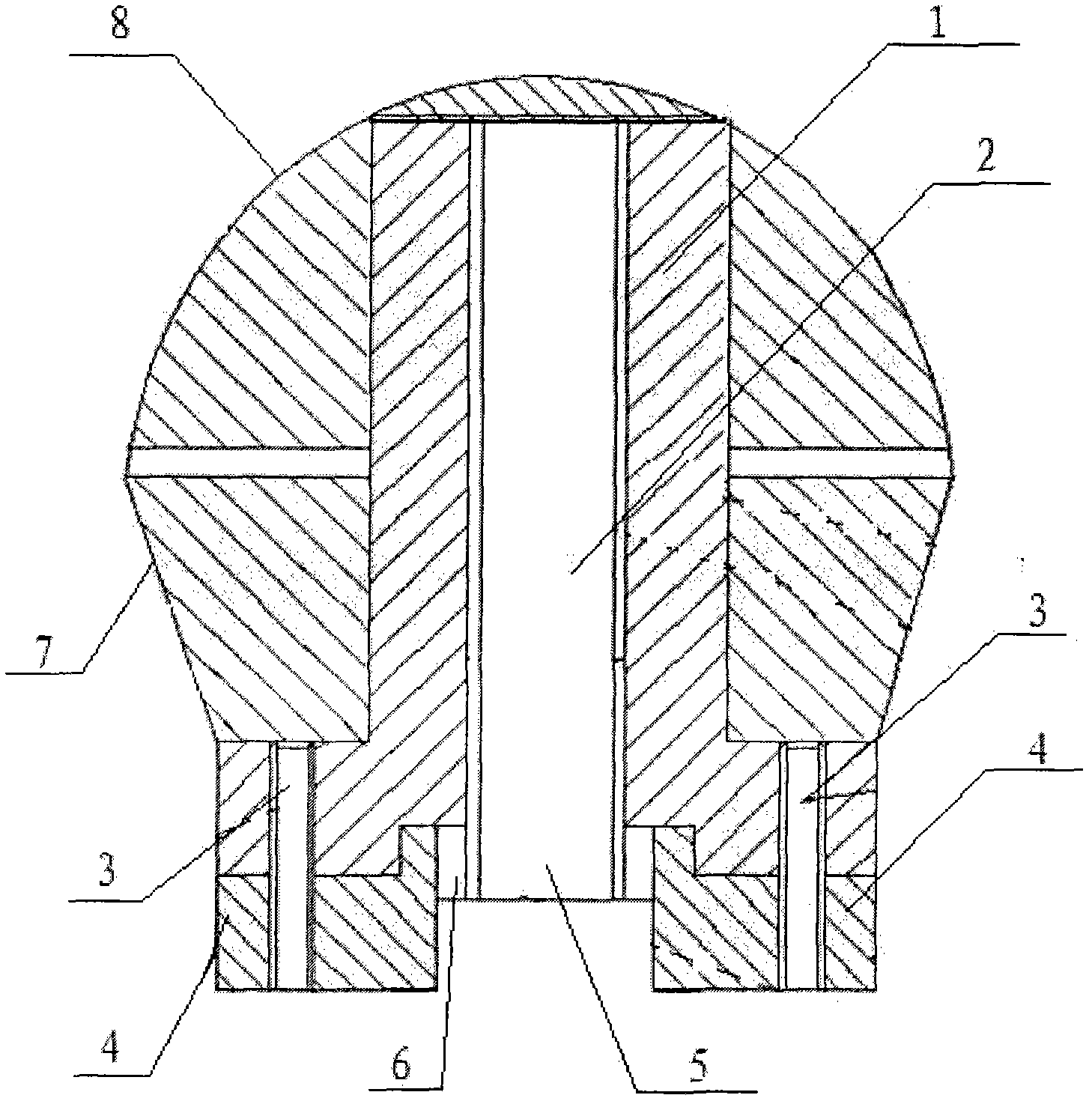

[0008] Install the positioning flange (3) on the top of the connecting rod (1) with bolts (4) and fastening bolts (7), and install the lead screw (2) from the middle hole of the positioning flange (3) to the In the threaded hole of the connecting rod (1), a shaft sleeve (6) is arranged at the part of the screw rod (2) and the screw shaft (5). The free dimensions of the central aperture are the same.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Disclosed is a novel press machine link mechanism. A positioning flange is installed on a connecting link through bolts and fastening bolts. A lead screw is installed from the inside of a middle part hole of the positioning flange to the inside of a threaded hole of the connecting link. A shaft sleeve is arranged in the parts of the lead screw and a screw shaft, and the free size of the external diameter of the shaft sleeve is the same as the free size of a center unthreaded hole of the positioning flange. Due to the fact that the positioning flange can compulsorily ensure that the axis of the connecting link and the axis of the positioning flange are concentric, and thereby the defect that deformation occurs or even damage occurs among threads caused by the fact that the partial stress of the threads is excessive due to unbalance loading of stress of the connecting link is overcome.

Description

technical field [0001] The invention relates to a connecting rod mechanism, in particular to a novel press connecting rod mechanism, which belongs to the technical field of forging machinery. Background technique [0002] The connecting rod is an important functional part of the press. They transmit pressure by the cooperation of the internal and external threads of the two. At the same time, the adjustment of the working mechanism of the press is realized by the adjustability between the two threads. At present, in actual use During the process, it often happens that the thread between the two is difficult to adjust, and even the thread is damaged. Since the pressure transmission of the connecting rod is not always along the axis of the two, the stress between the threads occurs. Partial load, excessive local force, resulting in deformation or even damage between threads. Contents of the invention [0003] The object of the present invention is to provide a novel press l...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21J9/18

Inventor 王传平

Owner 王传平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com