Novel connecting device for connecting rod and ball screw rod

A technology of connecting device and connecting rod, which is applied in the field of forging machinery, can solve the problems of difficult adjustment, damage and equipment damage of connecting rod and ball screw thread, and achieve the effect of avoiding excessive force on the thread locally.

Inactive Publication Date: 2012-12-05

李克信

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a novel connection device for connecting rods and ball screw rods, which overcomes the problem of the existing press connecting rods and ball screw rods due to the use of direct threaded connections: The pressure transmission of the screw rod during work is not always carried out along the axes of the two, which may easily lead to unbalanced loading of the force between the threads, excessive local force, and deformation or even damage between the threads; and thus As a result, the thread between the connecting rod and the ball screw is not easy to adjust, or the equipment is damaged.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

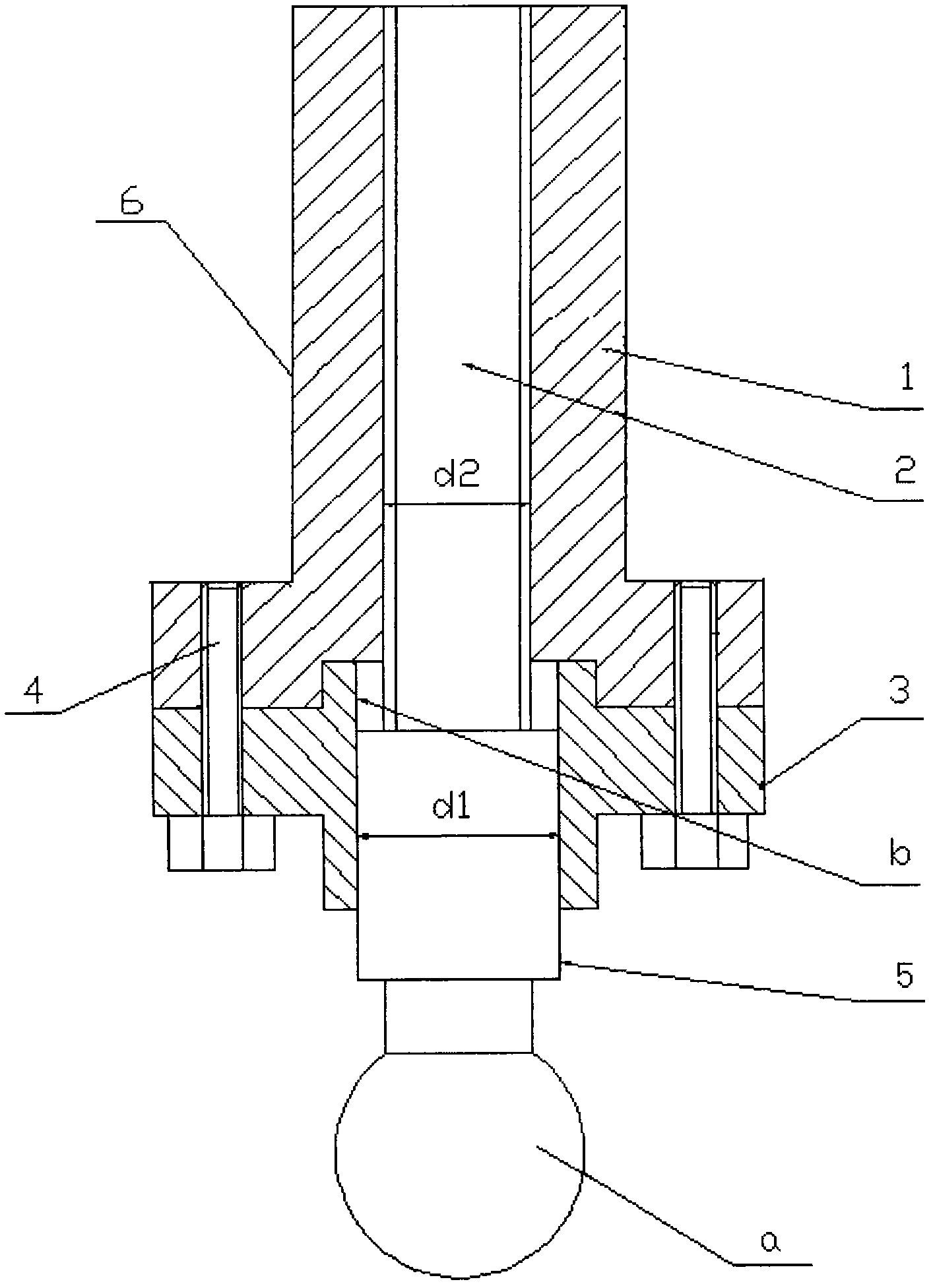

[0008] Fix the positioning flange 3 on the lower port of the connecting rod 1 with the bolt 4, and install the ball screw 2 from the middle hole of the positioning flange 3 into the threaded hole of the connecting rod 1; The part of the rod 2 close to the ball head a is provided with a ball head light cylinder 5 , the size d1 of the ball head light cylinder 5 is the same as the free size of the center b of the positioning flange 3 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A novel connecting device for a connecting rod and a ball screw rod is fixedly arranged at the lower port part of the connecting rod by using bolts through a positioning flange; a ball head screw rod is arranged in a thread hole of the connecting rod through a middle hole of the positioning flange; a ball head polished cylinder is arranged at a part, which is close to a ball head, of the ball head screw rod; and the size of the ball head polished cylinder is identical with the free size of the center of the positioning flange. The positioning flange can mandatorily enable the axis of the ball head screw rod to be concentric with the axis of the positioning flange, so that the defect that parts among threads deform and are damaged due to the fact that local parts of the threads are excessively stressed because unbalanced loading exists in the stress between the connecting rod and the ball head screw rod and the defect that the threads between the connecting rod and the ball head screw rod are not easy to adjust or damage accidents of the equipment occur due to that the parts among threads deform and are damaged are avoided.

Description

technical field [0001] The invention relates to a connection device between a connecting rod and a ball screw, in particular to a novel connection device between a connecting rod and a ball screw, and belongs to the technical field of forging machinery. Background technique [0002] The connecting rod and the ball screw are important functional parts of the press. They transmit pressure by the cooperation of the internal and external threads of the two, and at the same time, the adjustment of the working mechanism of the press is realized by the adjustability between the two threads. At present, in the actual use process, it often happens that the thread between the two is difficult to adjust, and even the thread is damaged. The main reason for this phenomenon is that the connection mechanism between the connecting rod and the ball screw is through two The thread of the other is directly connected, this connection method is not reasonable, because the pressure transmission b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21J9/02

Inventor 李克信

Owner 李克信

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com