Novel device for connecting press connecting rod and ball screw rod

A connecting device and press technology, applied in presses, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve problems such as thread deformation, local force, damage, etc., to avoid thread localization The effect of overstressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

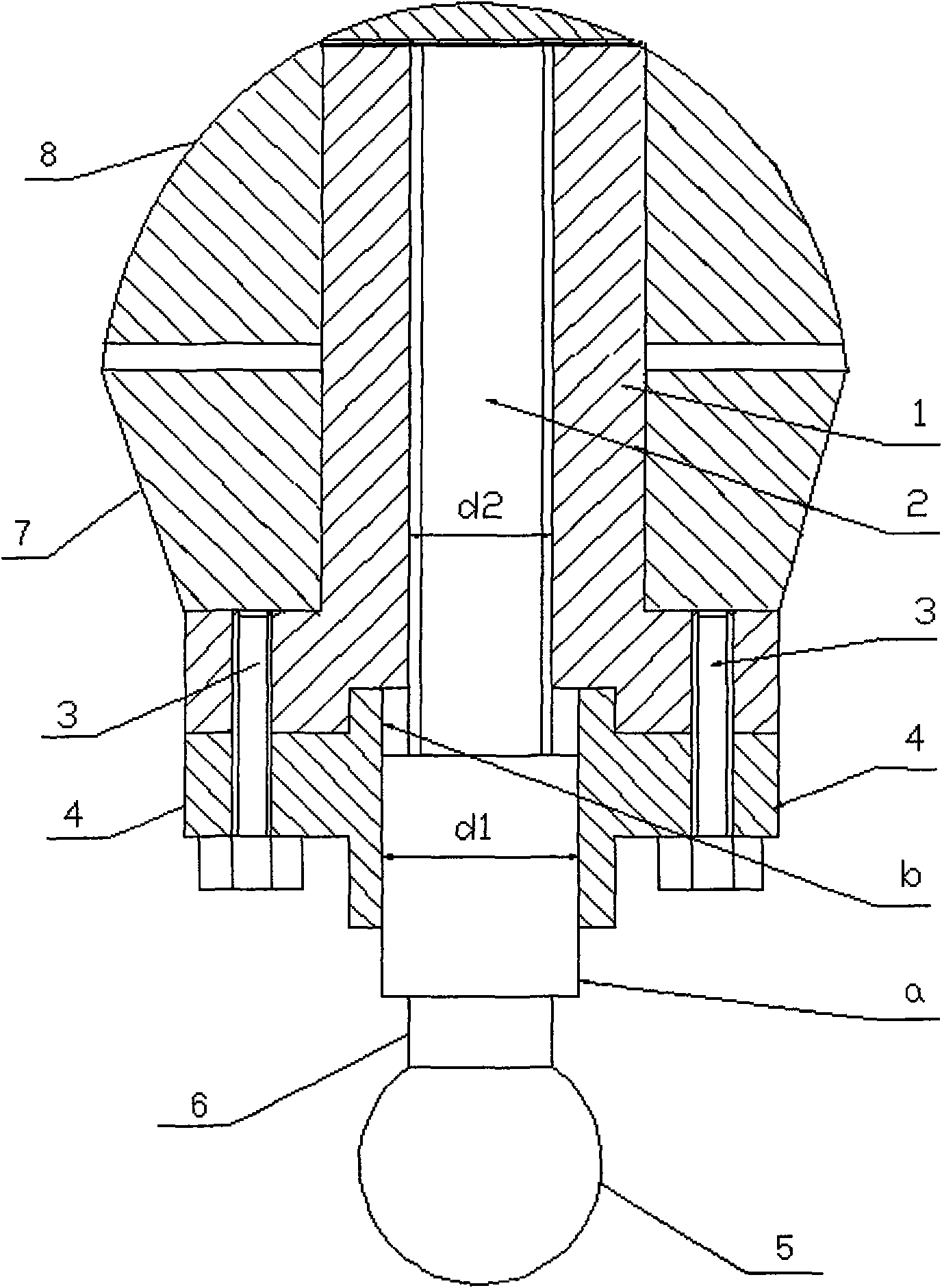

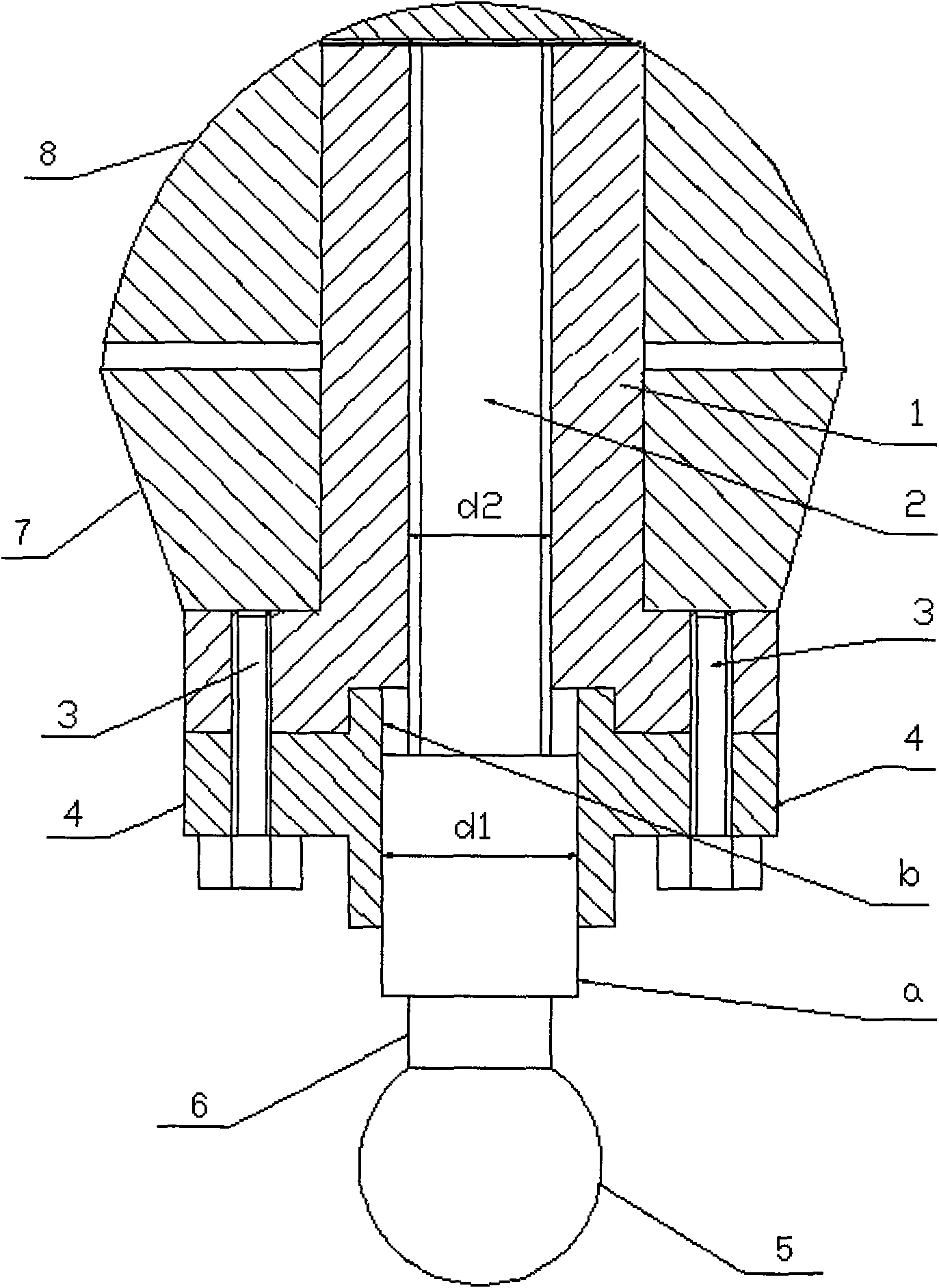

[0008] Fix the positioning flange (3) on the lower port of the connecting rod (1) with bolts (4) and fastening bolts (7). ) is concentric and fixed on the body (8), and the ball screw (3) is installed in the threaded hole of the connecting rod (1) from the middle hole of the positioning flange (3). At the same time, when installing the positioning flange (3), ensure that the axis of the light hole of the flange is concentric with the axis of the thread hole on the connecting rod (1). The large diameter d2 of the internal thread on the rod (1) or the large diameter of the external thread on the ball screw (2) is made in the part of the ball screw (2) and the ball head (5) close to the ball head A section of ball head light cylinder (6), the free size of the outer diameter of the ball head light cylinder (6) is the same as the free size of the central light hole of the positioning flange, and the two form a slight clearance fit in tolerance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com