Device and method for testing foaming performance of surfactant under high-temperature and high-pressure conditions

A surfactant, high temperature and high pressure technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of less foam, difficult to measure, high instrument cost, etc., achieve good promotion and application prospects, low production cost, and more foam Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

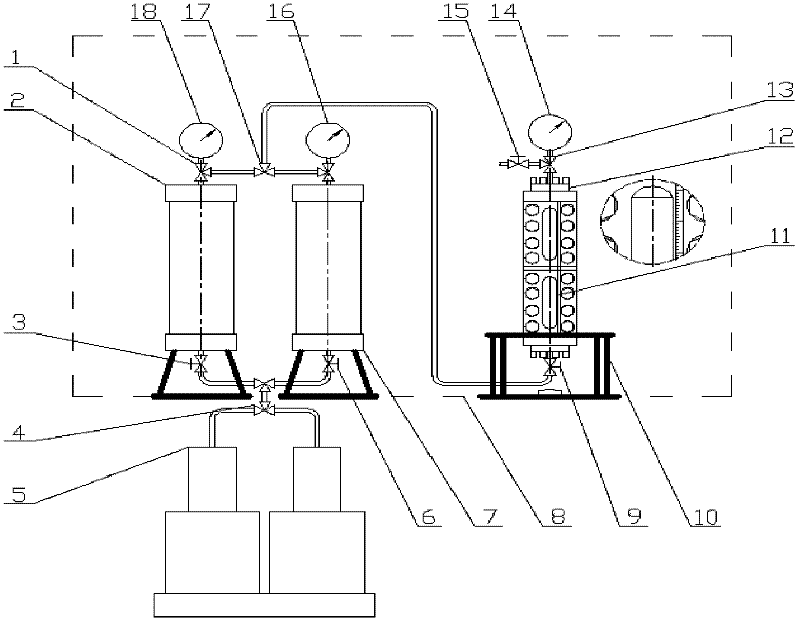

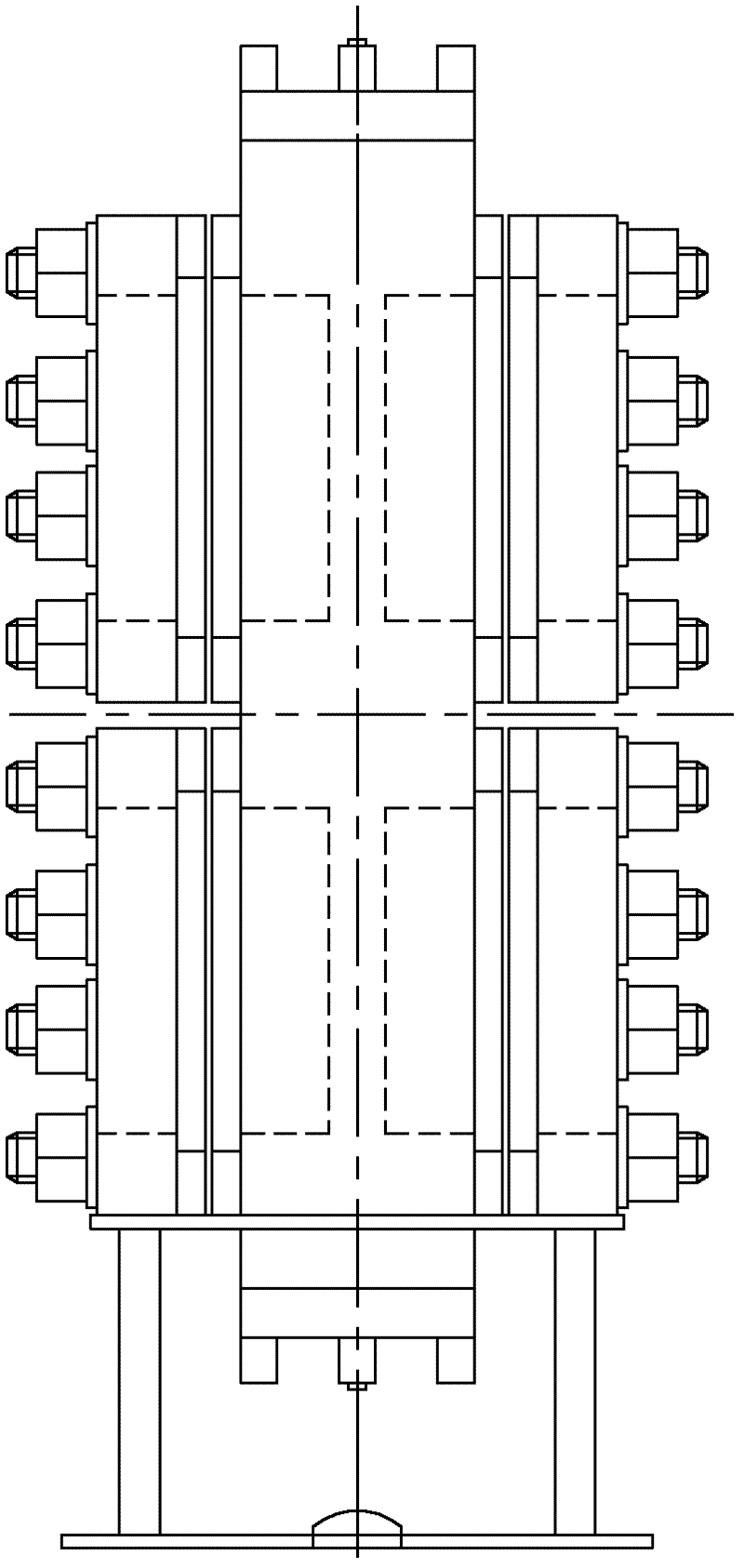

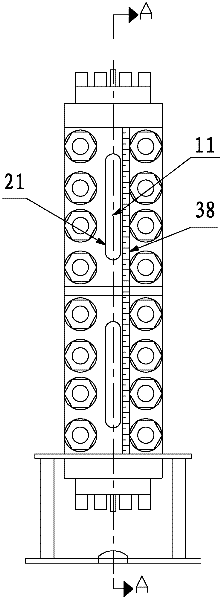

[0028] This device described in the present invention, its overall structure is as follows figure 1 As shown, it is composed of high-pressure constant-speed constant-pressure pump 5, No. 1 piston container 2, No. 2 piston container 7, reactor 12 and constant temperature box 8. The high-pressure constant-speed constant-pressure pump, No. 1 piston container, and No. 2 piston container Both the container and the reactor are vertically fixed and placed in a temperature-adjustable thermostat;

[0029] Wherein, the two outlet ports of the high-pressure constant-speed constant-pressure pump are combined and output through the outlet three-way valve of the high-pressure constant-speed constant-pressure pump, and then respectively pass through the inlet valve of the No. 1 piston container and the inlet valve of the No. 2 piston container and are connected to the The bottoms of No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com