Thermostatic control valve

A thermostatic control valve and valve body technology, applied in the field of machinery, can solve the problems of cumbersome maintenance, complex system structure, inability to close the thermostatic control valve, etc., and achieve the advantages of simplified HVAC system pipeline, high stability and high practical value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

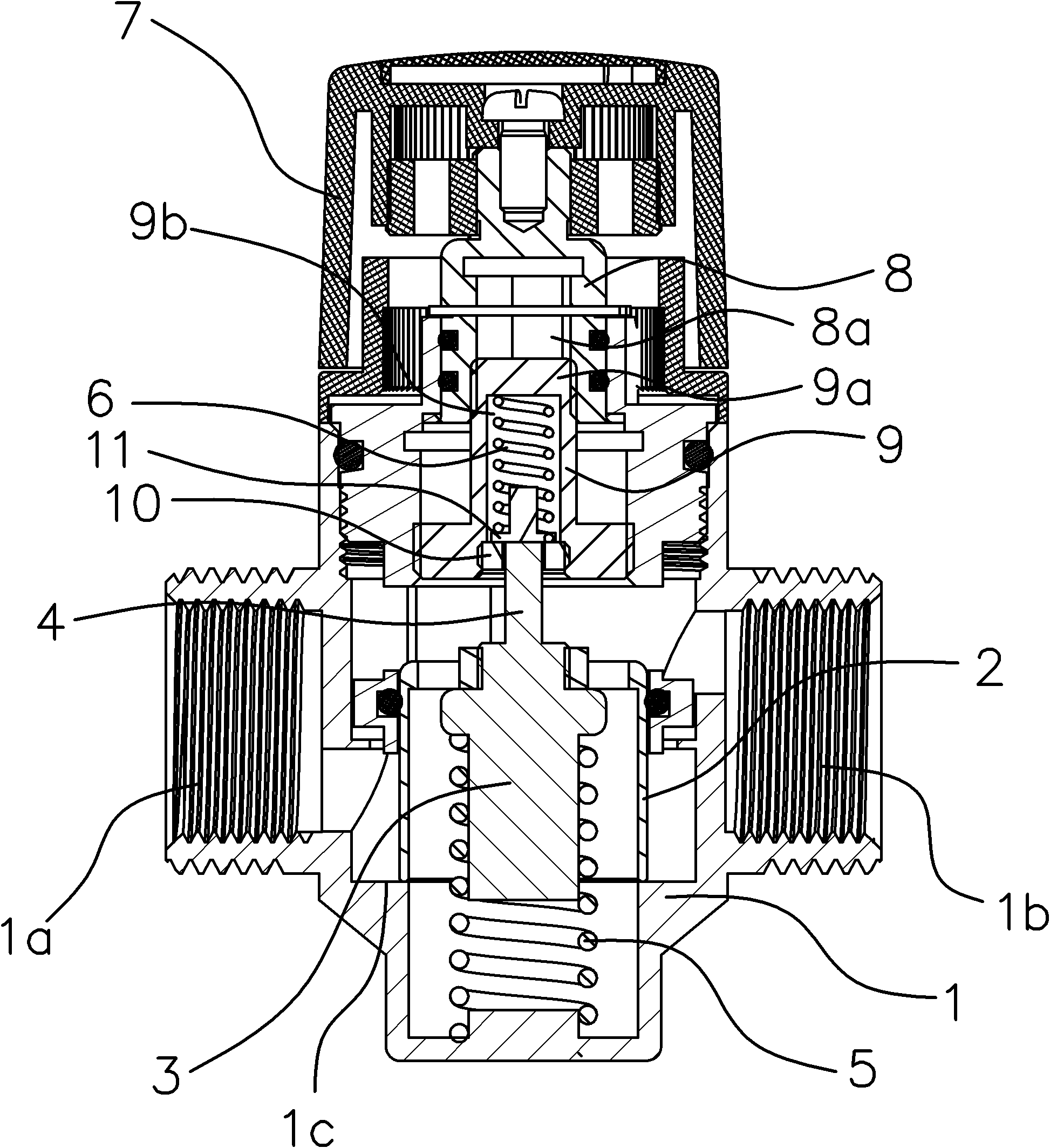

[0042] Such as figure 1 As shown, the thermostatic control valve includes a valve body 1 with a cavity inside, the two ends of the valve body 1 are the water inlet 1a and the water outlet 1b respectively, and the cavity between the water inlet 1a and the water outlet 1b is the fluid supply The water cavity through which the medium passes.

[0043] The spool 2 is set at the water cavity of the valve body 1 and can block the water cavity after it moves. There is also a thermal expansion device on the spool 2, and a spring is set between the spool 2 and the bottom of the valve body 1. a 5.

[0044] The thermal expansion device is composed of a thermal expansion sleeve 3 and a thermal expansion tube 4 arranged in the thermal expansion sleeve 3. The thermal expansion sleeve 3 is filled with a thermal expansion agent, and one end of the thermal expansion tube 4 is located in the thermal expansion sleeve 3. The thermal expansion tube 4. The other end stretches out the thermal expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com