Ink nozzle preparation method

An ink filling and ink injection technology, which is applied in printing and other directions, can solve the problems of poor performance of ink filling nozzle products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preparation method of the ink filling nozzle of the present invention will be described in detail below with reference to the accompanying drawings.

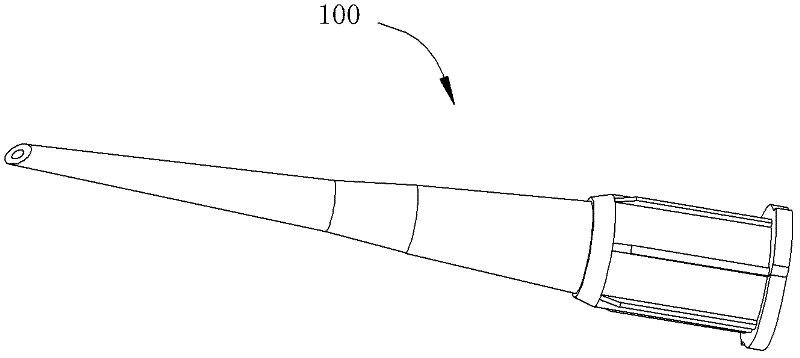

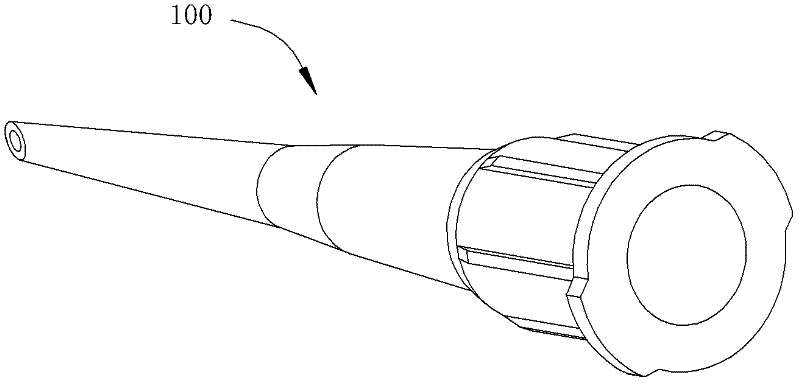

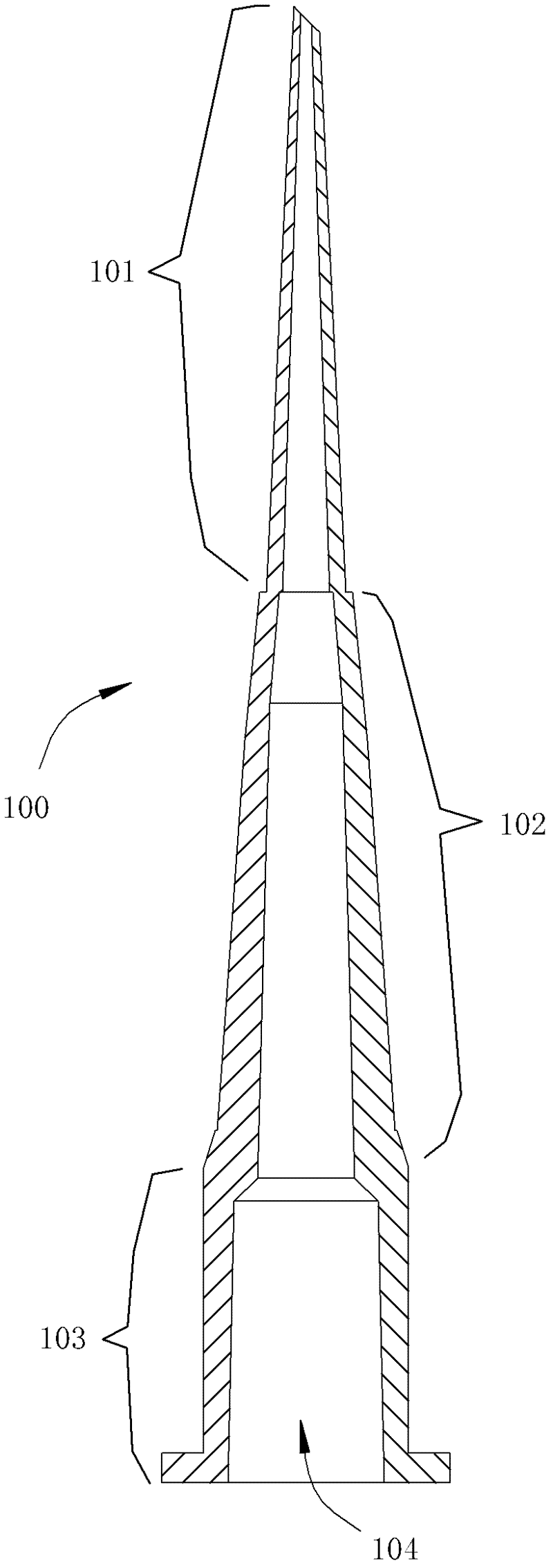

[0017] see figure 1 , 2 , 3, respectively show the perspective view and cross-sectional view of the ink filling nozzle prepared by the method of the present invention under different viewing angles.

[0018] The ink filling nozzle 100 is installed at the outlet of the ink replenishment bottle to undertake the task of ink output. It is mainly composed of an ink filling section 101 , a bridge section 102 and a base section 103 connected in sequence. The ink filling section 101 undertakes the task of being inserted into the ink filling hole of the ink cartridge. The base section 103 undertakes the task of connecting the ink replenishment bottle. The diameters of the outer tubes of the base section 103 , the bridge section 102 and the ink injection section 101 gradually shrink in sequence until reaching the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com