A guide rail device for plastic pipe welding

A technology for plastic pipes and guide rails, which is applied in the field of plastic processing, can solve the problems of unguaranteed pipe welding quality, high randomness of operation, hidden quality problems, etc., and achieve the effect of ensuring the coaxiality of welding, convenient insertion depth, and avoiding randomness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the present invention will refer to the prior art for the parts that are the same as those of the prior art.

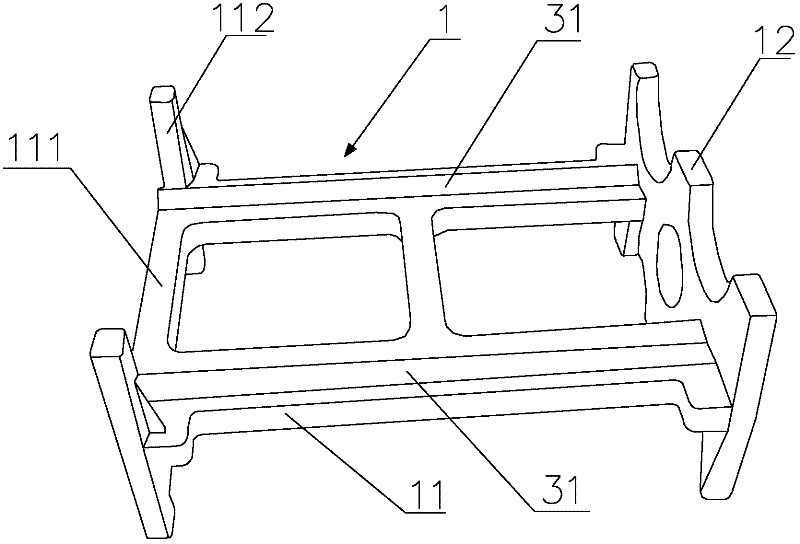

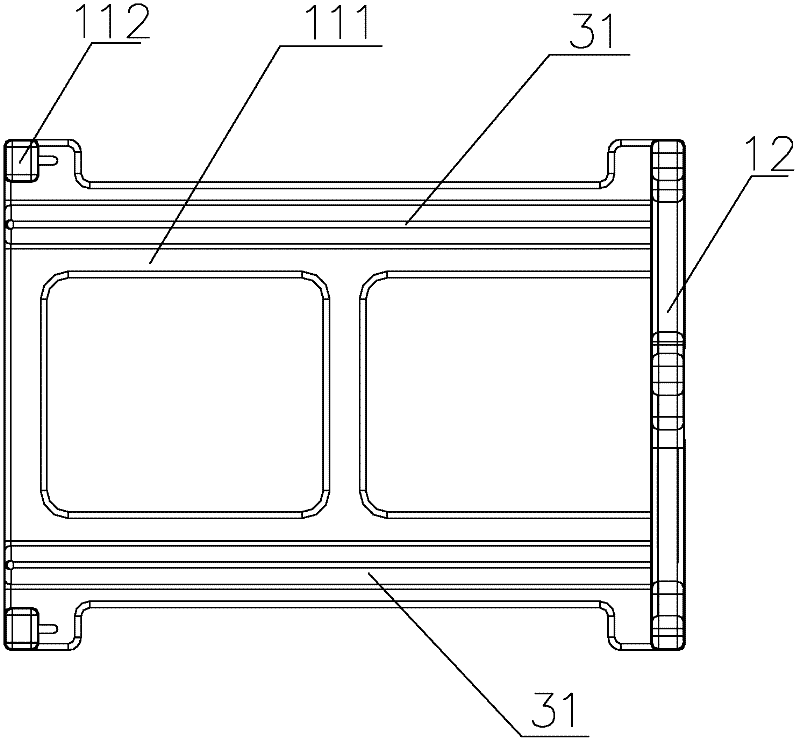

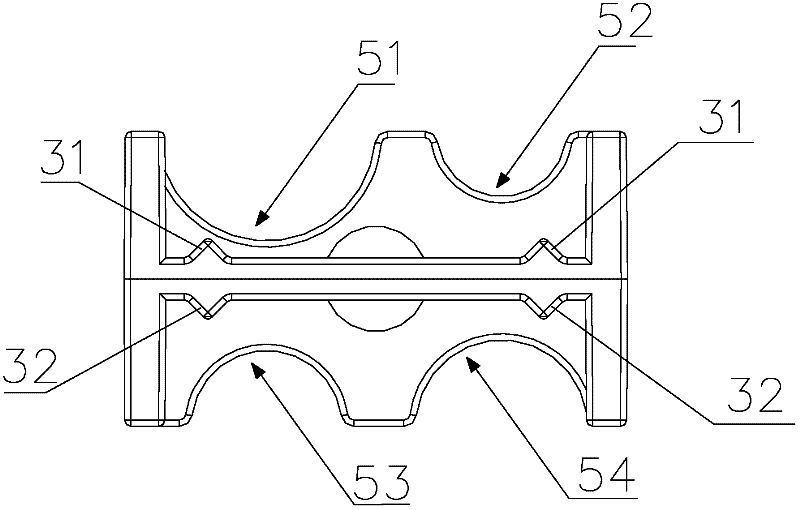

[0024] Such as Figure 1-Figure 8 As shown, the guide rail for plastic pipe welding of the present invention includes a base 1 and two sliders 2, which are respectively slider I21 and slider II22, the base 1 includes a bracket 11 and a baffle 12, and the baffle The plate 12 is integrally formed with the bracket 11, the bracket 11 has a horizontal part 111 and a vertical part 112, and on both sides of the top and back of the horizontal part 111 of the bracket, there are rails 31 and 32 protruding from the plane and having a triangular cross-section , on both sides of the bottom surface of the slider I21 and the slider II22, there are grooves 41 and 42 that match the shape of the rail and have a triangular cross-section; on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com