A minimally invasive expandable channel system with a new polymer material built-in fiber optic spine

A polymer material and built-in optical fiber technology, applied in the field of spinal minimally invasive surgery system, can solve the problems of inconvenient force to open the forceps, inability to grasp the insertion depth of the cannula, and high replacement cost of the fixed arm, so as to achieve cost reduction and reduction Effects of cross-infection, device fabrication and replacement cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

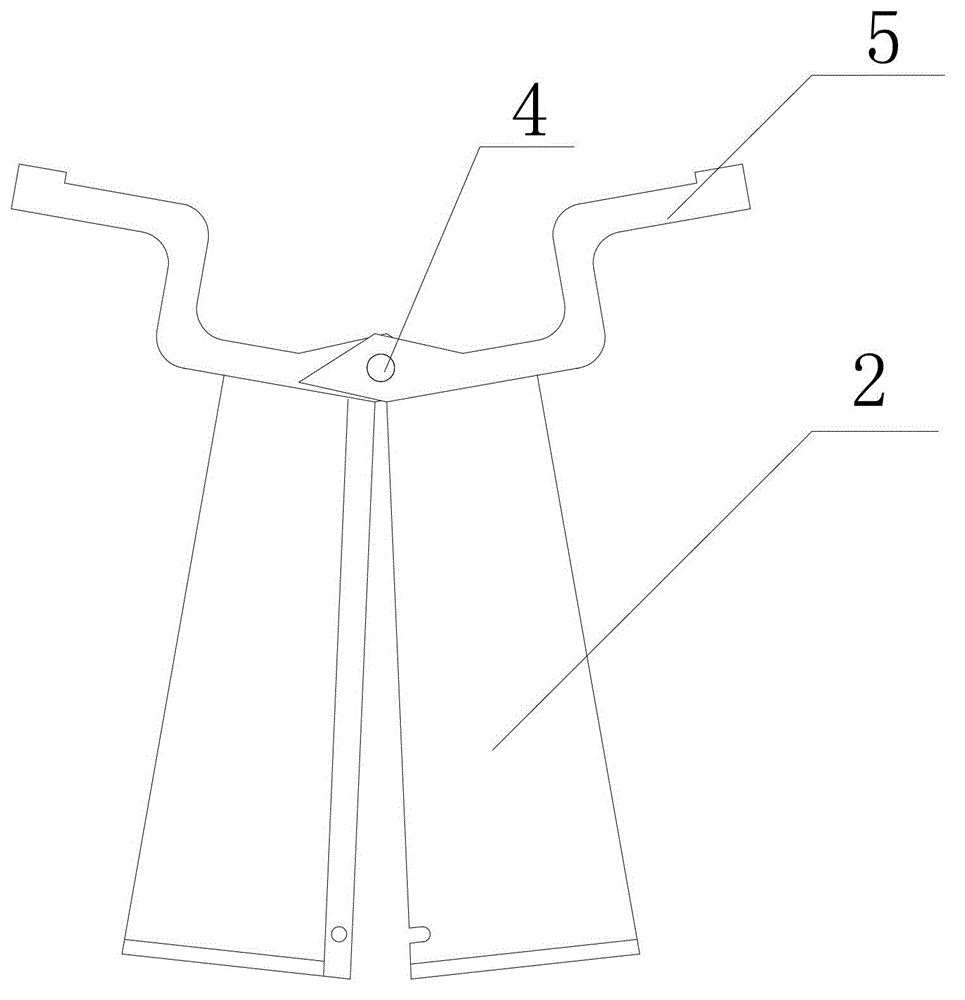

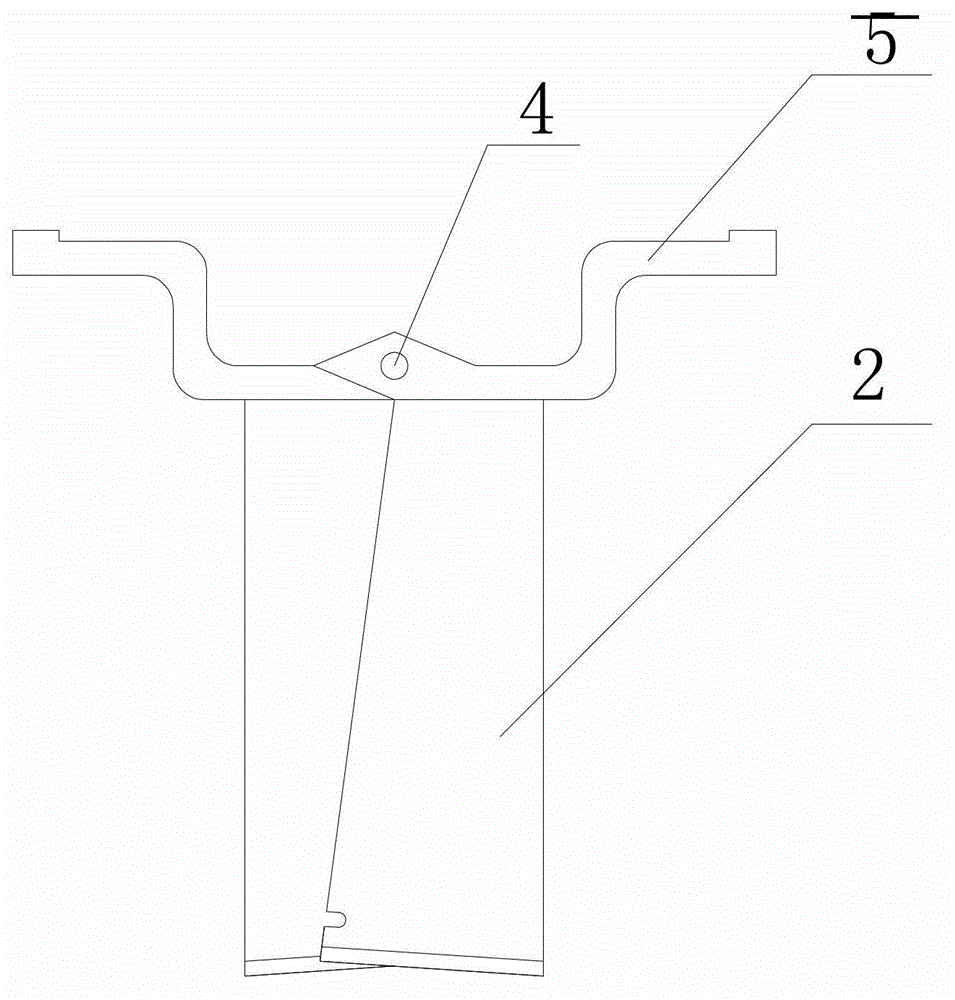

[0031] Such as Figure 1-Figure 8 As shown, the minimally invasive and expandable channel system for the spinal cord with built-in polymer material of the present invention consists of a distraction sleeve 1 , a working sleeve 2 and a fixed arm 3 .

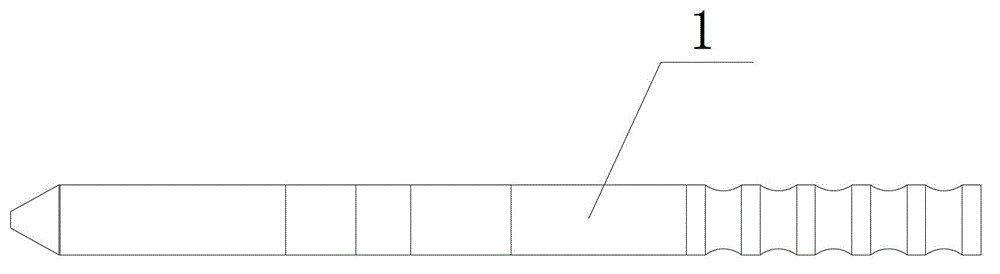

[0032] Such as figure 1 As shown, the stretching sleeve 1 is used to place the incision of the target surgical part of the patient, and then insert the working sleeve 2 after stretching the surgical area. Starting from the bottom of the cone, color identification sections of different lengths are set, which are green 5cm, pink 1cm, yellow 1cm, and blue 3cm. The different color identification sections are different from the scale, so that the approximate range of insertion depth can be quickly determined, and it is easy to grasp the insertion depth. The rear end of the expansion sleeve 1 is provided with a plurality of anti-slip segments, which can effectively increase the convenience of use and facilitate the insertion of the exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com