Composite sheet based on glassy carbon and carbon additives and method for its preparation

A technology of composite thin plates and additives, applied in the field of composite materials, can solve problems such as difficult graphitization, long production cycle, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

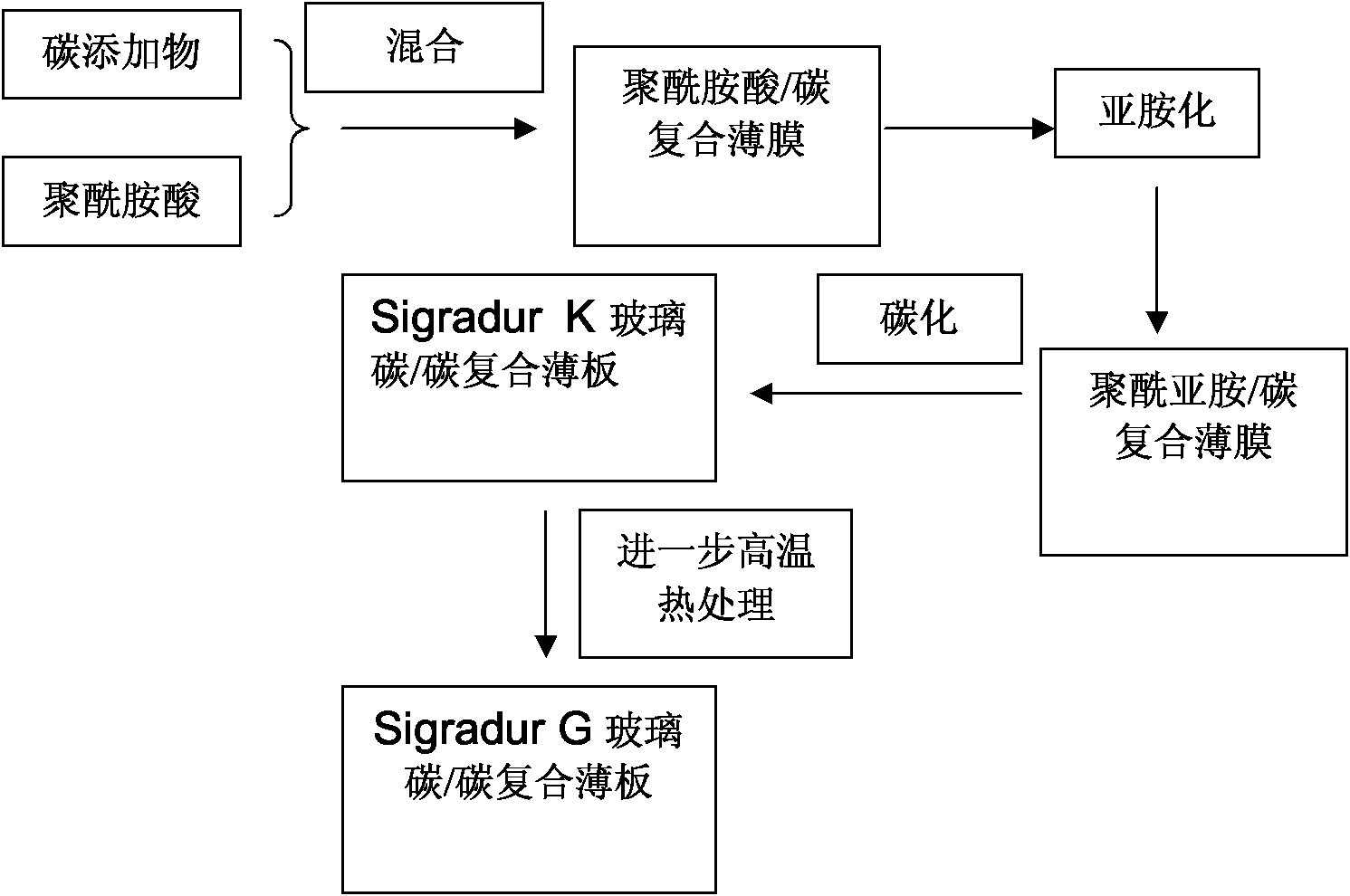

Method used

Image

Examples

Embodiment 1

[0028] The randomly arranged PAN-based chopped carbon fibers with a volume percentage of 20% and an average length of about 10 mm are immersed in a N, N-dimethylacetamide solution of polyamic acid (PMDA / ODA system) with a solid content of 10% , place the mixture on the substrate, control the thickness to 300 microns, heat at 60°C for 1 hour, at 90°C for 1 hour, at 120°C for 1 hour, and at 150°C for 1 hour. After removing the polar solvent, place in a vacuum oven at 180 ℃ for 1 hour, 200°C for 1 hour, 250°C for 1 hour, and 300°C for 1 hour to complete the imidization, thereby forming a polyimide precursor / carbon composite film with a thickness of about 30 microns. The obtained composite film has a tensile strength of 230 MPa.

Embodiment 2

[0030] The procedure was the same as in Example 1, replacing the randomly arranged PAN-based chopped carbon fibers with randomly arranged long carbon fibers. The composite film obtained at this time had a tensile strength of 300 MPa.

Embodiment 3

[0032] The procedure was the same as in Example 1, replacing the randomly arranged PAN-based chopped carbon fibers with woven long carbon fibers. The tensile strength of the composite film obtained at this time was 700 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap