Calibration device for verticality detection ruler of construction engineering quality detector group

A technology of construction engineering and calibration device, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of imperfect calibration items, inability to meet the verticality detection ruler, unreliable positioning datum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

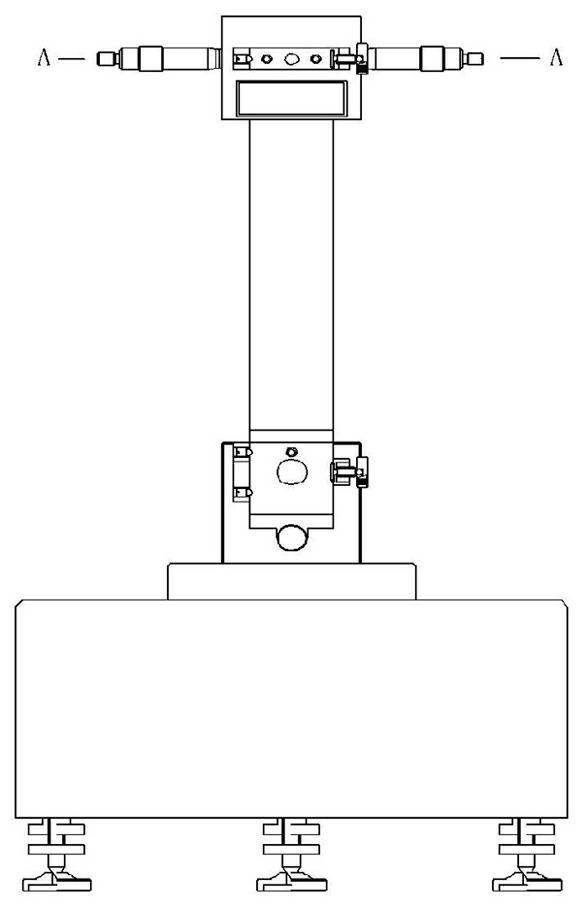

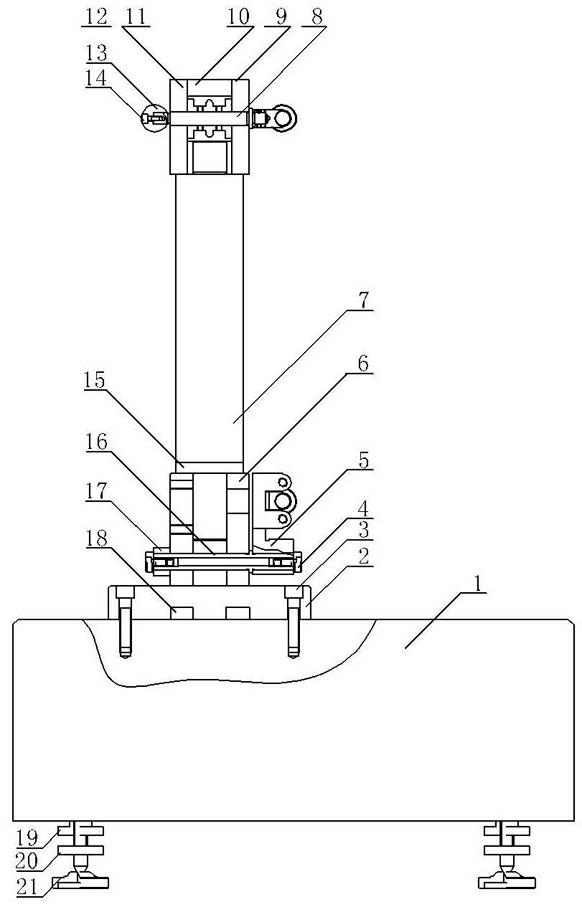

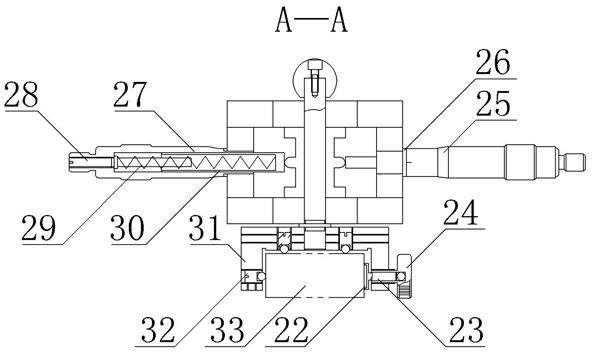

[0017] like figure 1 , 2 , shown in 3, a kind of construction engineering quality detector group verticality detection ruler calibration device, comprises base 1, is installed on the base 1 and is equipped with the verticality detection ruler installation positioning structure of verticality detection ruler 36, is characterized in that : The installation and positioning structure of the verticality detection ruler is set on the base 1 through the flange 2, the base 3 is positioned on the base 1 by the flange 2, the rotary shaft 4 is installed on the base 3, and the ruler base 5 is located on the rotary shaft 4 One side of the guide shaft seat 13 is connected with the base 3 through the connecting rod 11, the guide shaft 16 is fixed in the guide plate through the guide sleeve 17, and the measuring base 19 is installed on the side of the guide shaft 16; the rotation angle calibration mechanism is connected through the guide sleeve 17 The guide shaft 16 is fixed on the guide sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com