Method for eliminating local wear of working roller of CVC (continually variable crown) mill

A technology for local wear and work rolls, applied in rolling mill control devices, keeping roll equipment in an effective state, metal rolling, etc., can solve problems such as high-order wave shape, influence, coating, coiling process product quality influence, etc. To achieve the effect of eliminating local wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

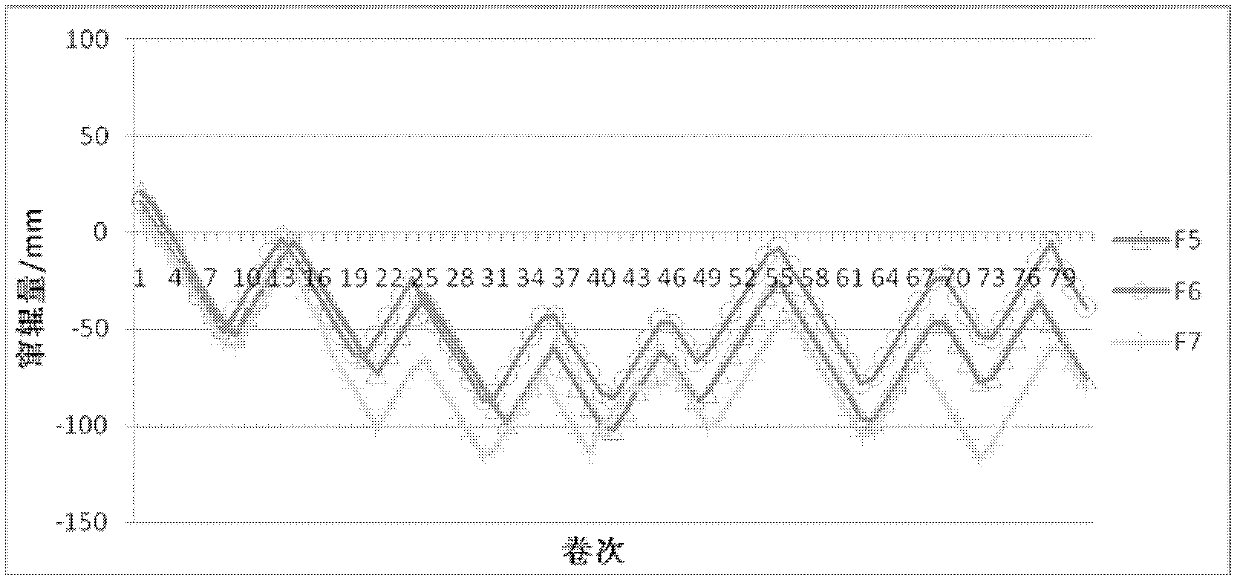

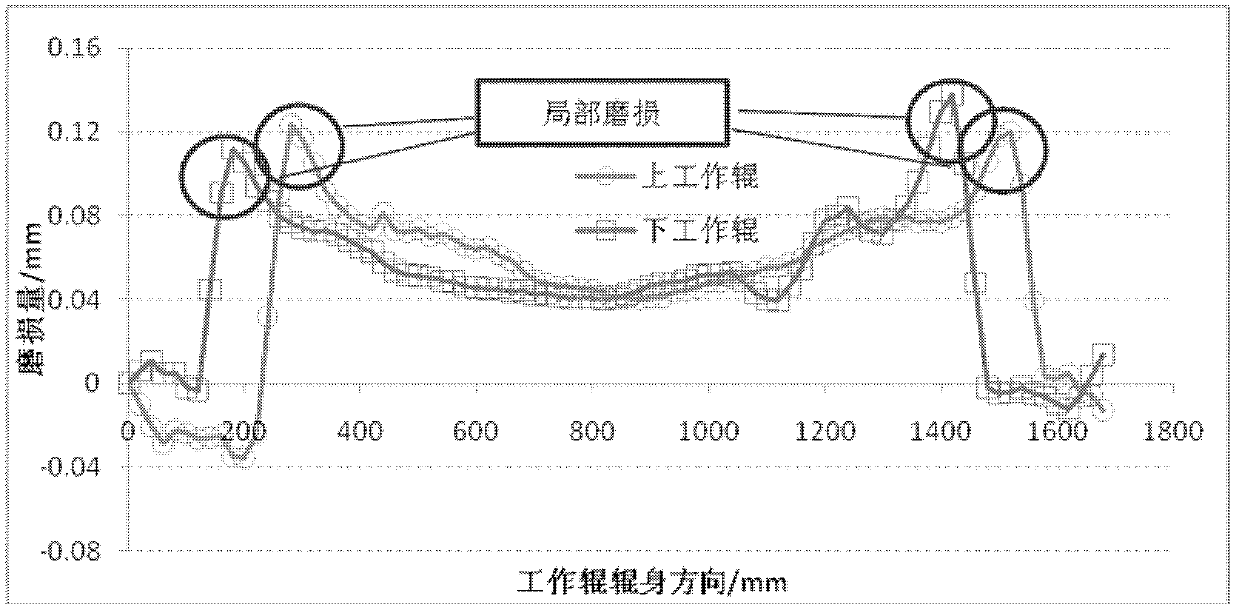

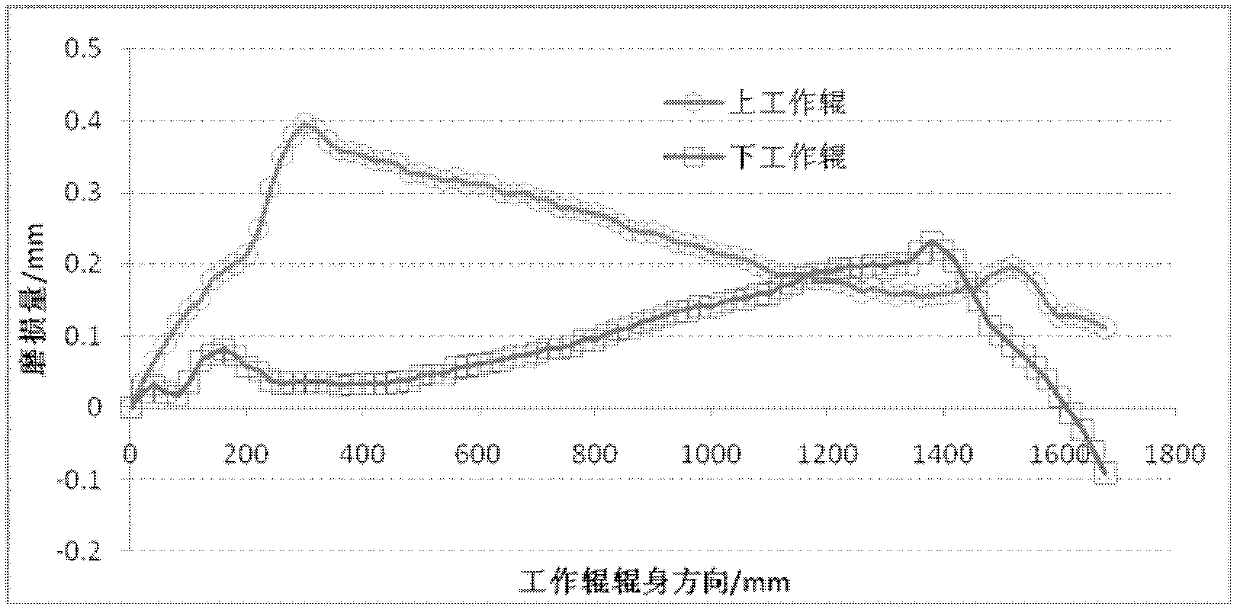

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0034] Embodiments of the present invention provide a method for eliminating local wear of work rolls of a CVC rolling mill, comprising the following steps:

[0035] (1) Set the work roll shifting step length δ (δ>0mm) and the upper limit F of bending force compensation UL , Bending force compensation lower limit F BL , so that the work roll shifting increment ΔD = δ;

[0036] In order to ensure the effect of periodic roll shifting of the work rolls to eliminate the local wear of the work rolls, and at the same time reduce the influence of changes in the amount of roll shifting on the shape of the strip, the step length of the work roll shifting is set to δ = 10mm;

[0037] In order to ensure that the periodical roll shifting amplitude of the work rolls can meet the needs of eliminating the local wear of the work rolls, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com