Flexible hydraulic jaw

A hydraulic pliers, flexible technology, applied in the field of flexible hydraulic pliers, can solve the problems of different curvatures and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

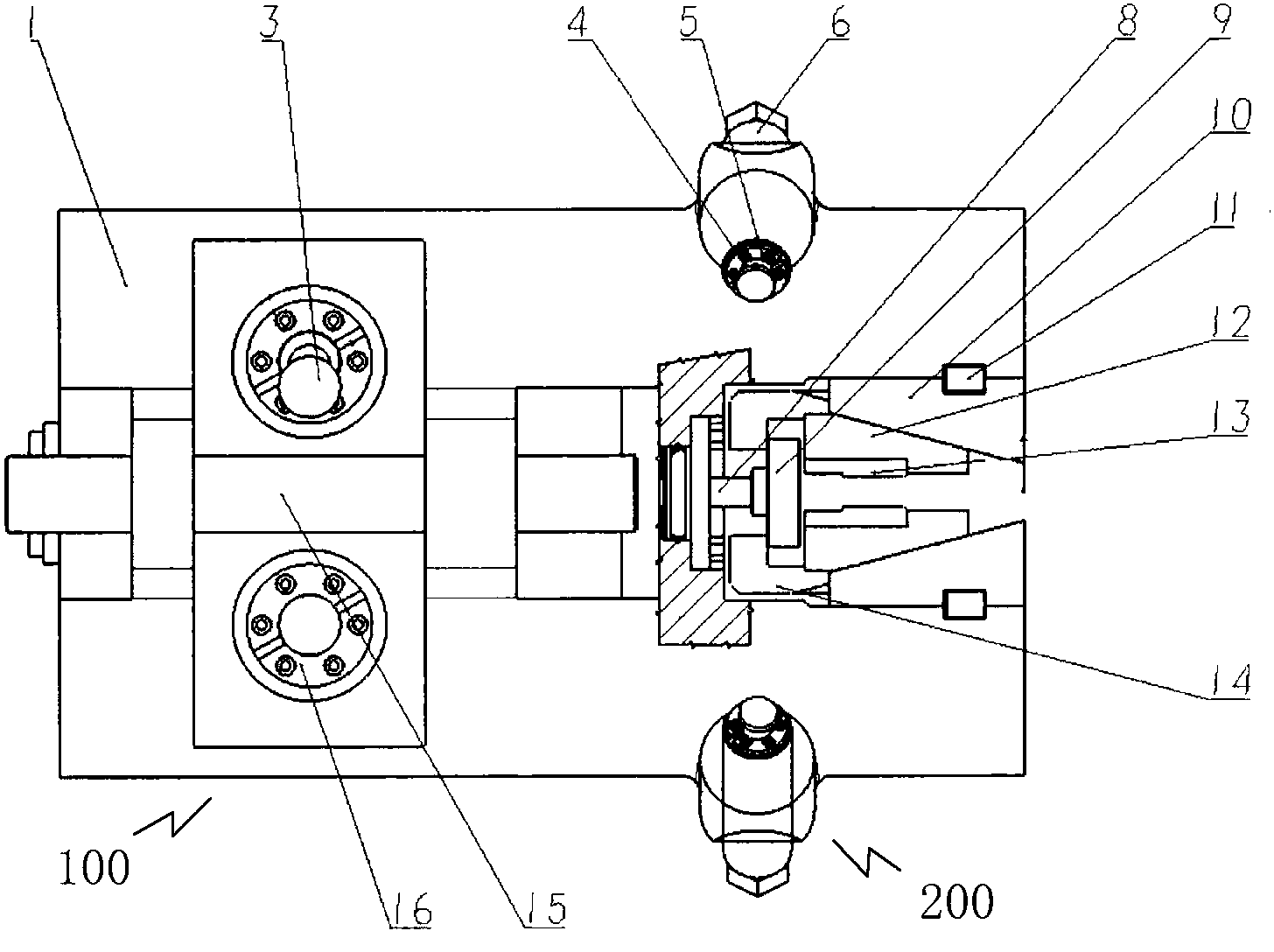

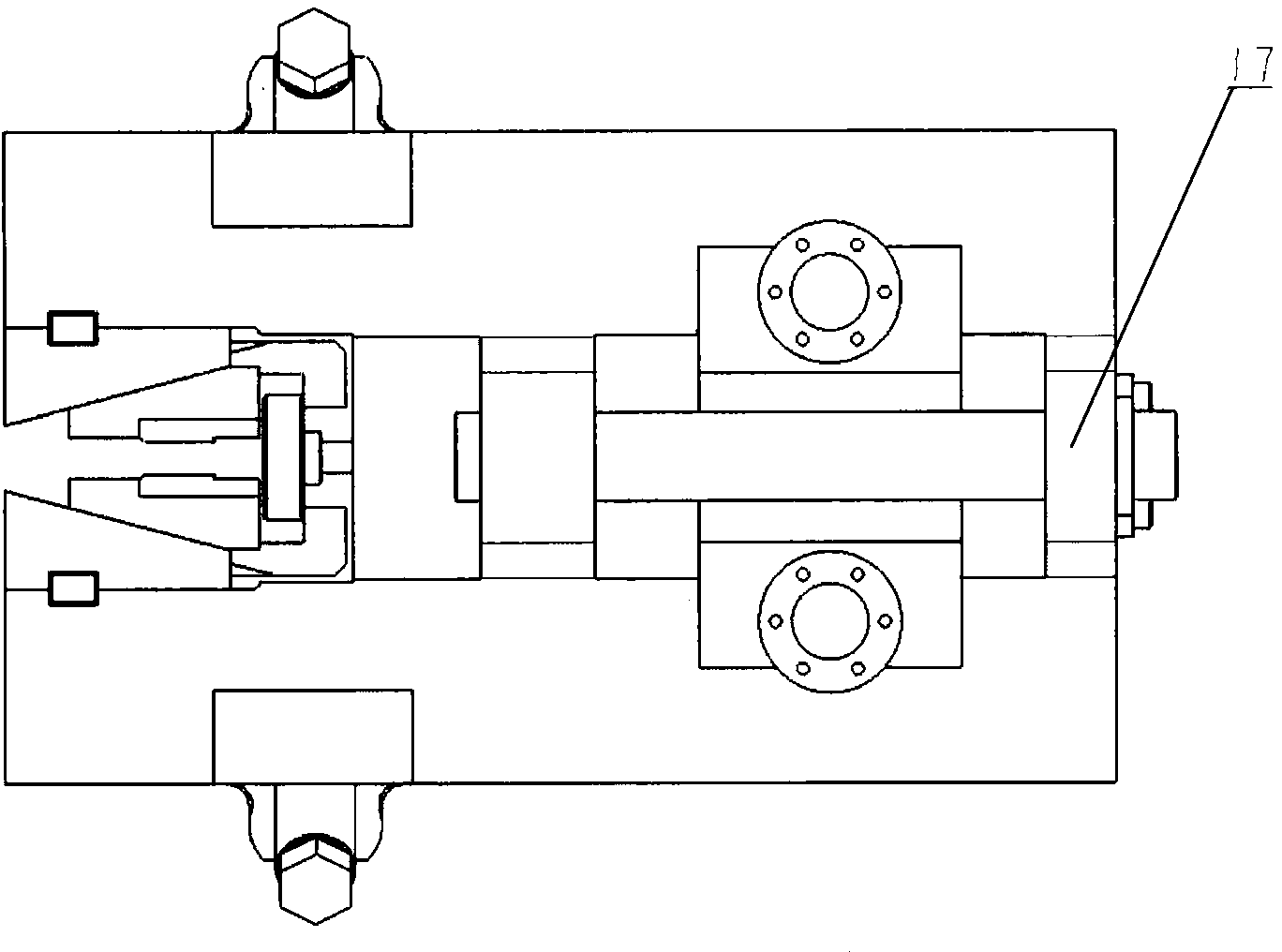

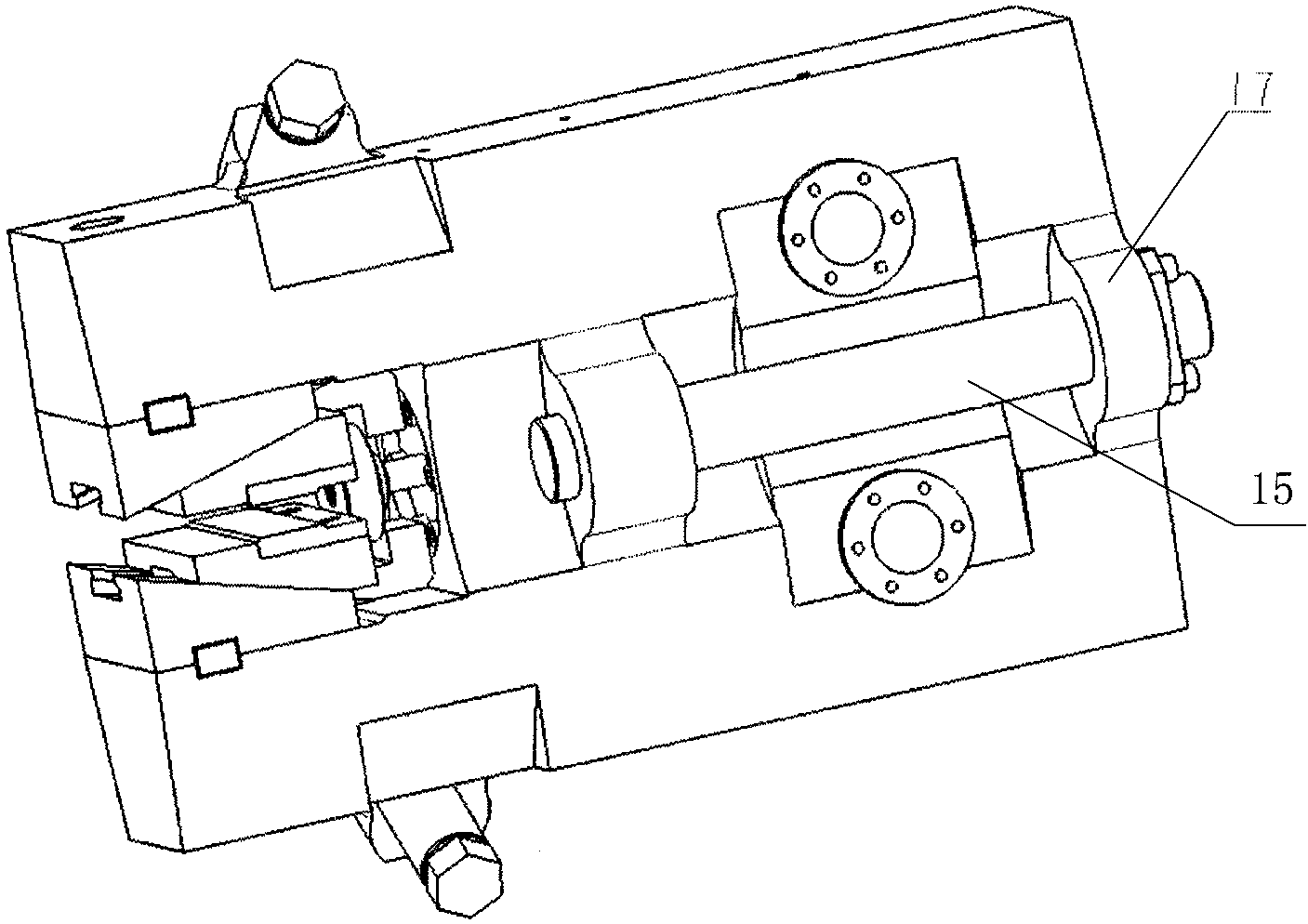

[0014] like Figure 1 to Figure 4 As shown, a flexible hydraulic jaw is provided with a double-acting hydraulic cylinder in the middle of the clamp body 1, and the top of the double-acting hydraulic cylinder piston 8 is movably connected with two symmetrically distributed guide rails 14 through a top block 9, and the two The inboard of guide rail 14 is respectively provided with wedge-shaped slide block 12, and the inboard surface of slide block 12 is provided with clamping spacer 13, is connected with wedge-shaped fixed block 10 by flat key 11 at clamp body 1, and the slope of fixed block 10 and The inclined planes of the slider 12 cooperate; two parallel lugs 17 are arranged on the front and rear surfaces of the clamp body 1 respectively, and a pin shaft 15 is arranged between the two lugs 17 on the rear surface. When multiple clamp bodies 1 are connected, the lugs 17 on the front surface are movably connected with the lugs 17 on the rear surface of the previous clamp body t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com